Method of consolidating precipitation-hardenable alloys to form consolidated articles with ultra-fine grain microstructures

a technology of nanocrystalline microstructure and precipitation hardening alloy, which is applied in the direction of metal-working apparatus, transportation and packaging, etc., can solve the problems of inability to induce large strains of very strong materials, such as tool steels, and significant uncertainty in the deformation field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

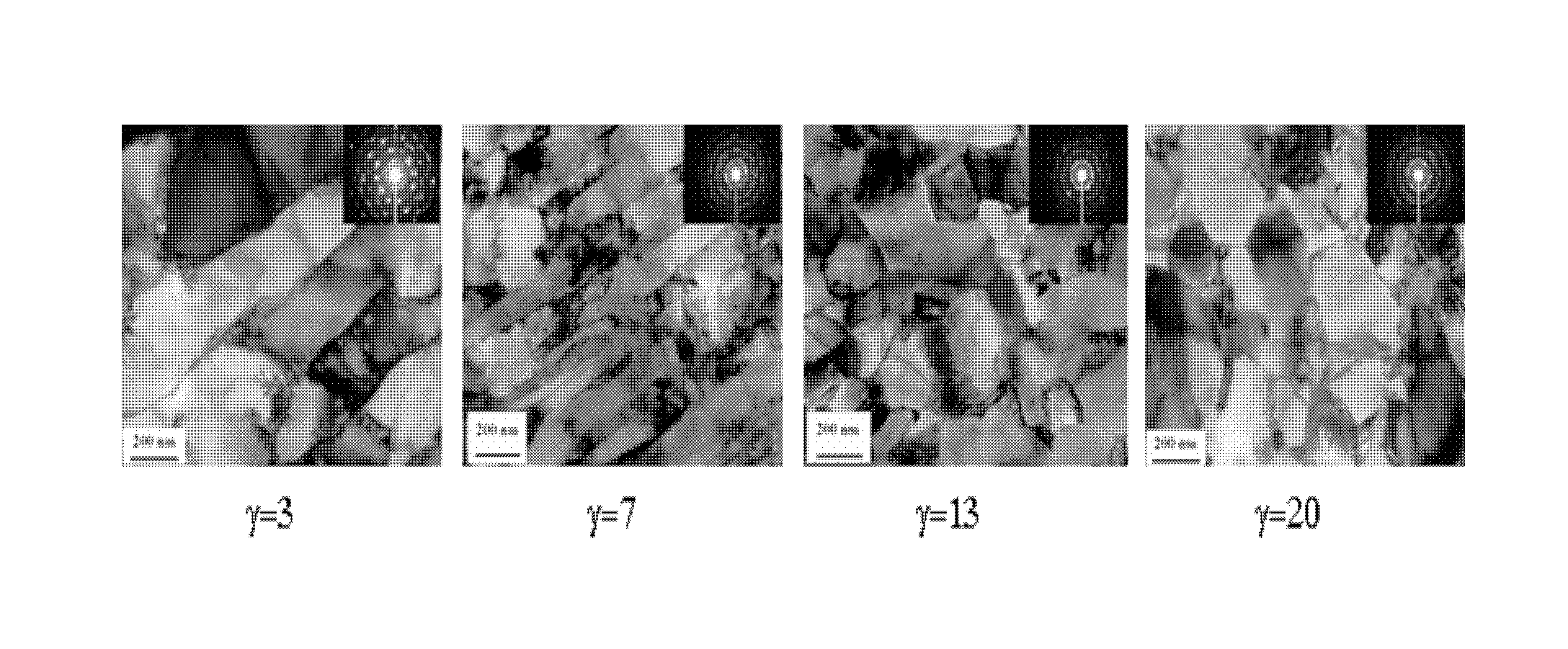

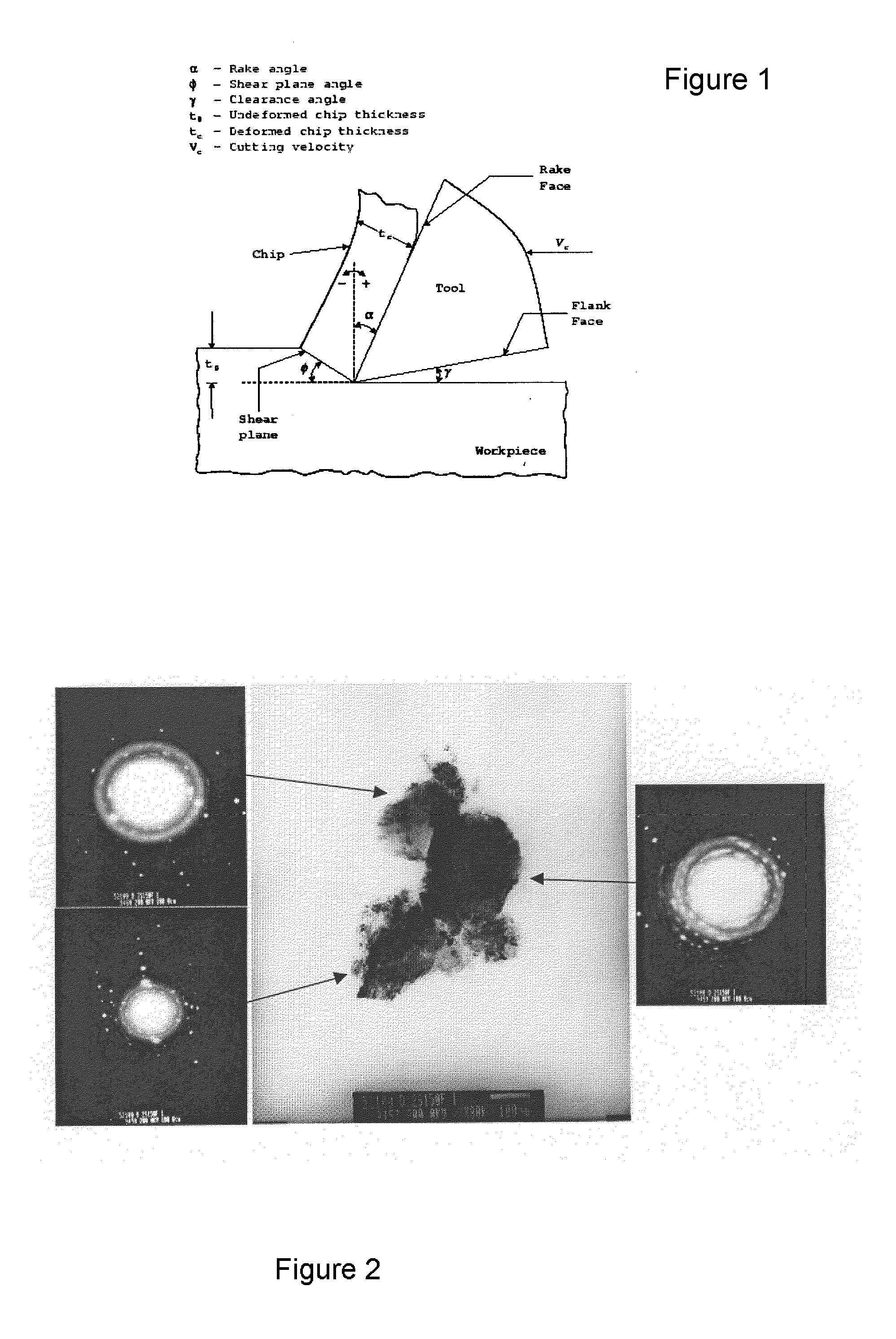

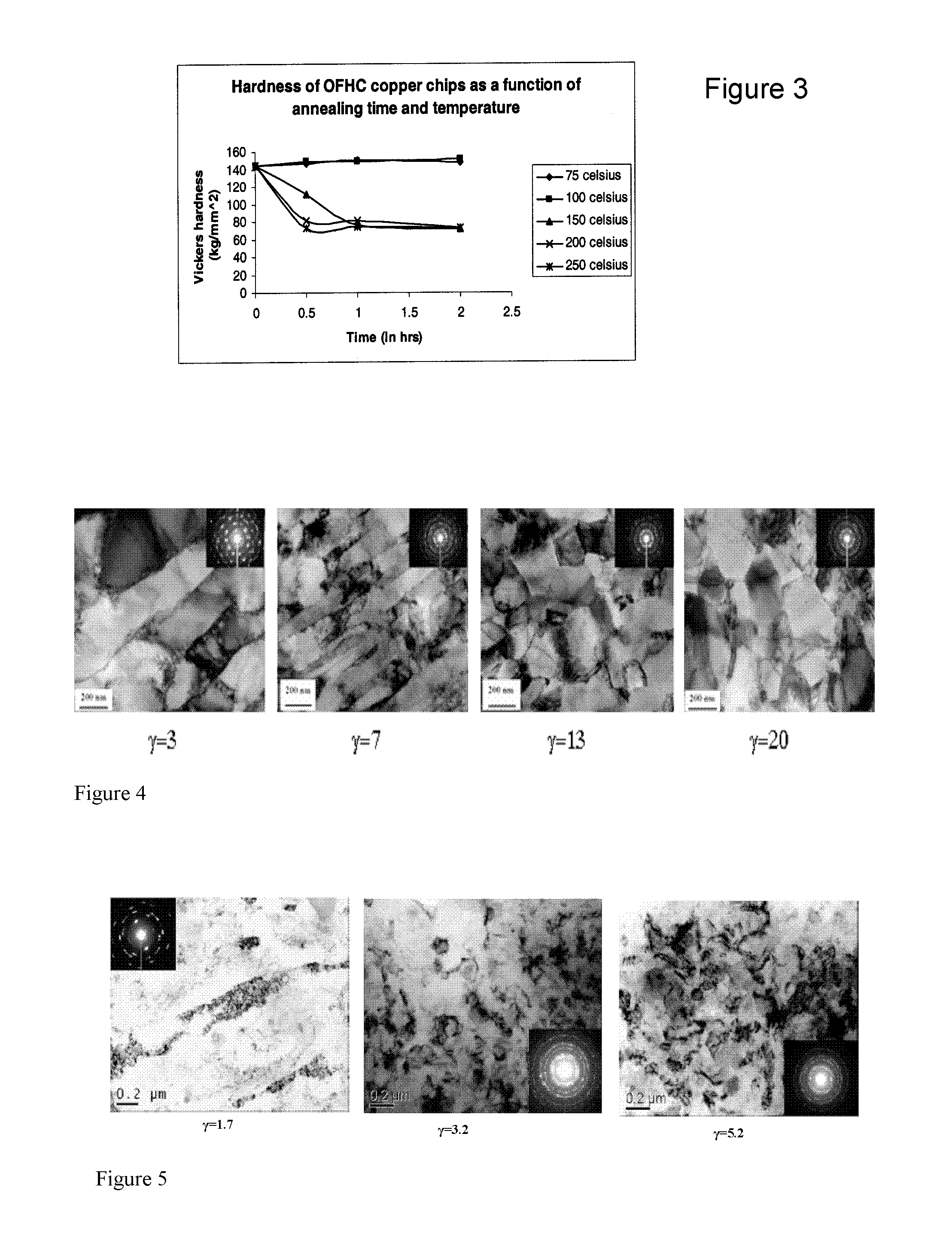

[0023] An investigation leading to this invention was undertaken to determine the microstructure and mechanical properties of chips produced by machining steels, and to explore the conditions under which they are produced. Steel cylinders of AlSI 52100, 4340 and M2 tool steel having diameters of about 15.7 mm were heat-treated by through-hardening and tempering to hardness values of about 60 to 62 Rc, about 56 to 57 Rc, and about 60 to 62 Rc, respectively. The initial microstructures of the steels prior to machining were tempered martensite. The compositions (in weight percent), austenitization temperatures (AC3) and approximate grain size (GS) of the steel specimens are summarized in Table 1 below.

TABLE 1Steel Type (AISI)434052100M2C0.38-0.431.000.8 Mn0.6-0.80.310.35Si0.15-0.3 0.260.35Cr0.7-0.91.454.52Ni1.65-2.000.140.2 Mo0.2-0.30.045.39P0.035 max0.009 max0.027 maxS0.040 max0.019 max0.005 maxV——2.09Cu—0.090.13Al——0.02Co——0.39W——6.86FebalancebalancebalanceAC3 (° C.)815-845775-8001...

PUM

| Property | Measurement | Unit |

|---|---|---|

| grain sizes | aaaaa | aaaaa |

| sizes | aaaaa | aaaaa |

| grain size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com