Method for preparing tungsten material through nanophase separation and sintering

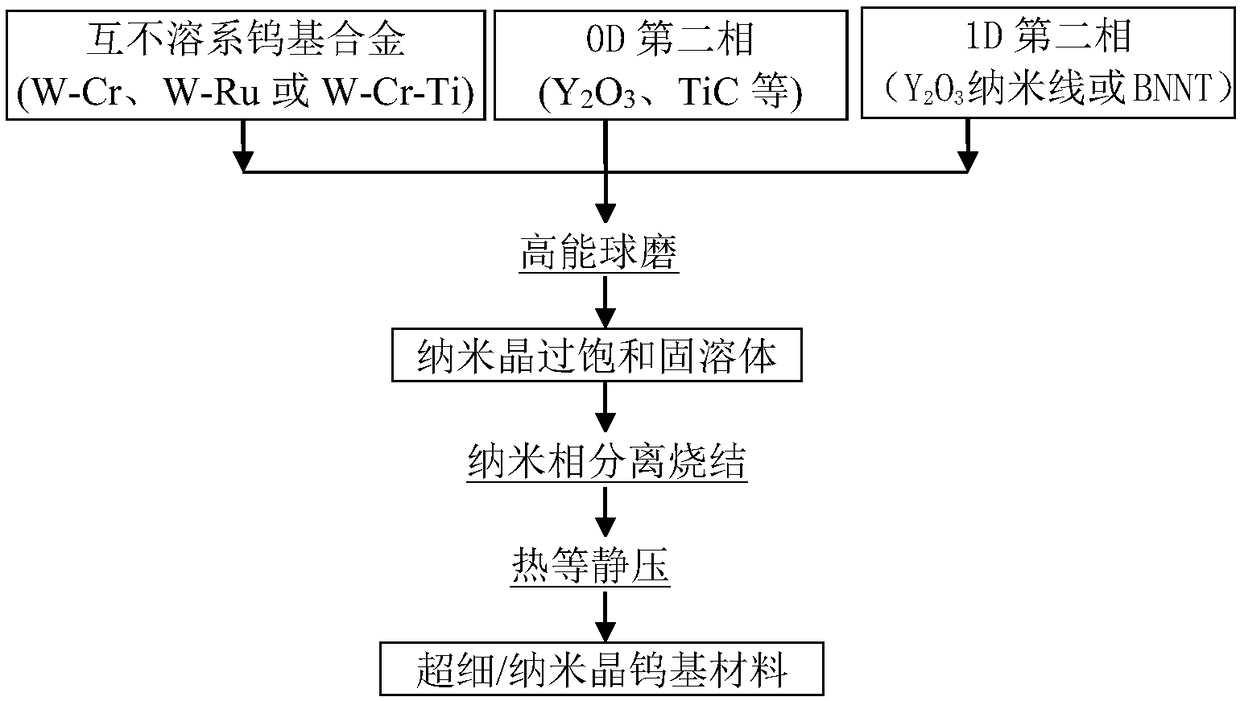

A technology for nano-phase separation and fine-grained tungsten material, which is applied in the field of nano-phase separation sintering to prepare tungsten materials, can solve the problems of decreased mechanical properties of grains at high temperature, weakened pinning effect, low stability, etc. The effect of grain growth and retention of nanocrystalline structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] Example 1: Y 2 o 3 Preparation of reinforced tungsten materials

[0017] Metal element powder and Y with a particle size of 20-30nm 2 o 3 Particles as raw materials, according to the composition of tungsten-based materials W-5wt.%Cr-0.5wt.%Y 2 o 3 Proportioning is carried out, and each component is pre-mixed evenly to obtain a pre-mixed powder. The premixed powders are mechanically alloyed on a planetary high energy ball mill. The ball milling jar is a tungsten ball milling jar, the grinding medium is carbide balls, the ball-to-material ratio is 15:1, and the rotation speed of the planetary ball mill is 500 rpm. After 48 hours of ball milling, the mechanically alloyed powder with the characteristics of nanocrystalline supersaturated solid solution was obtained. The mechanically alloyed powder is sintered in a vacuum atmosphere after compression molding or cold isostatic pressing, and the vacuum degree is 1×10 -4 Pa, the sintering temperature is 1500°C, and the h...

Embodiment 2

[0018] Example 2: Preparation of TiC-reinforced tungsten material

[0019] Using metal element powder and TiC particles with a particle size of 20-30nm as raw materials, the proportioning is carried out according to the composition of the tungsten-based material W-4wt.%Cr-0.5wt.%TiC, and each component is pre-mixed uniformly to obtain a pre-mixed powder. The premixed powders are mechanically alloyed on a planetary high energy ball mill. The ball milling jar is a tungsten ball milling jar, the grinding medium is carbide balls, the ball-to-material ratio is 20:1, and the rotation speed of the planetary ball mill is 700 rpm. After 40-60 hours of ball milling, a mechanically alloyed powder with the characteristics of a nanocrystalline supersaturated solid solution is obtained. The mechanically alloyed powder is sintered in a vacuum atmosphere after compression molding or cold isostatic pressing, and the vacuum degree is 1×10 -4 Pa, the sintering temperature is 1600°C, and the ho...

Embodiment 3

[0020] Embodiment 3: Preparation of BNNT reinforced tungsten material

[0021] Using metal element powder and particle size as boron nitride nanotube (BNNT) as raw material, according to the composition of tungsten-based materials W-5wt.%Cr-1wt.%Ti-0.5wt.%BNNT for proportioning, each component pre Mix evenly to obtain premixed powder. The premixed powders are mechanically alloyed on a planetary high energy ball mill. The ball milling jar is a tungsten ball milling jar, the grinding medium is carbide balls, the ball-to-material ratio is 18:1, and the rotation speed of the planetary ball mill is 600 rpm. After 60h of ball milling, the mechanically alloyed powder with the characteristics of nanocrystalline supersaturated solid solution was obtained. The mechanically alloyed powder is sintered in a vacuum atmosphere after compression molding or cold isostatic pressing, and the vacuum degree is 1×10 -4 Pa, the sintering temperature is 1500°C, and the holding time is 60min to obt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Grain | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com