Preparation method for 304 austenite stainless steel rotary blades of juicer

A technology of austenitic stainless steel and fruit juice machine, which is applied in the field of ion nitrogen carburizing process to change the performance of stainless steel, and can solve the problems of easy falling off and polluting the surface layer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

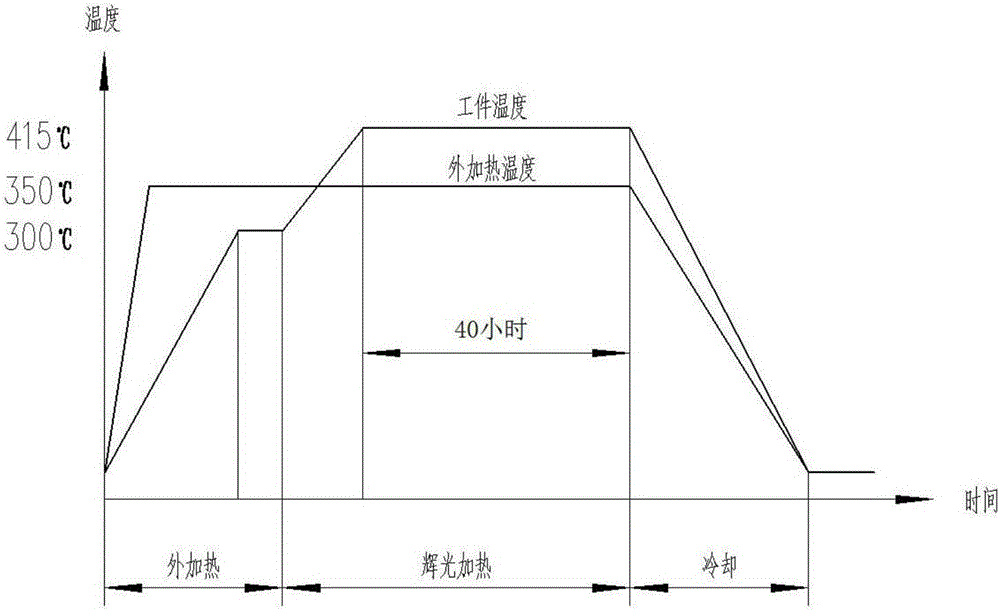

[0021] In the ion nitriding equipment (manufactured by Qingdao Fengdong Heat Treatment Co., Ltd., model: FD-WR120 / 150-150), the 304 austenitic stainless steel rotary blade of the fruit juice machine is subjected to plasma nitrocarburizing treatment.

[0022] The first step: Put the 304 austenitic stainless steel rotary blade of the fruit juice machine into the plasma equipment, and evacuate to a vacuum of 5 Pa;

[0023] Step 2: Nitrogen-filled external heating, fill the nitrogen to an atmospheric pressure, turn on the external heating, and the external heating temperature is 350°C;

[0024] Step 3: After the temperature of the blade reaches 300°C and is soaked, vacuumize to the ultimate vacuum;

[0025] Step 4: Plasma nitriding treatment, continuously inject hydrogen gas at 300ml / min and nitrogen gas at 900ml / min into the equipment, maintain the pressure in the furnace at 150Pa, and turn on the high-frequency power supply;

[0026] Step 5: Plasma nitrocarburizing treatment, k...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com