Preparation method of CuW/CuCr composite material

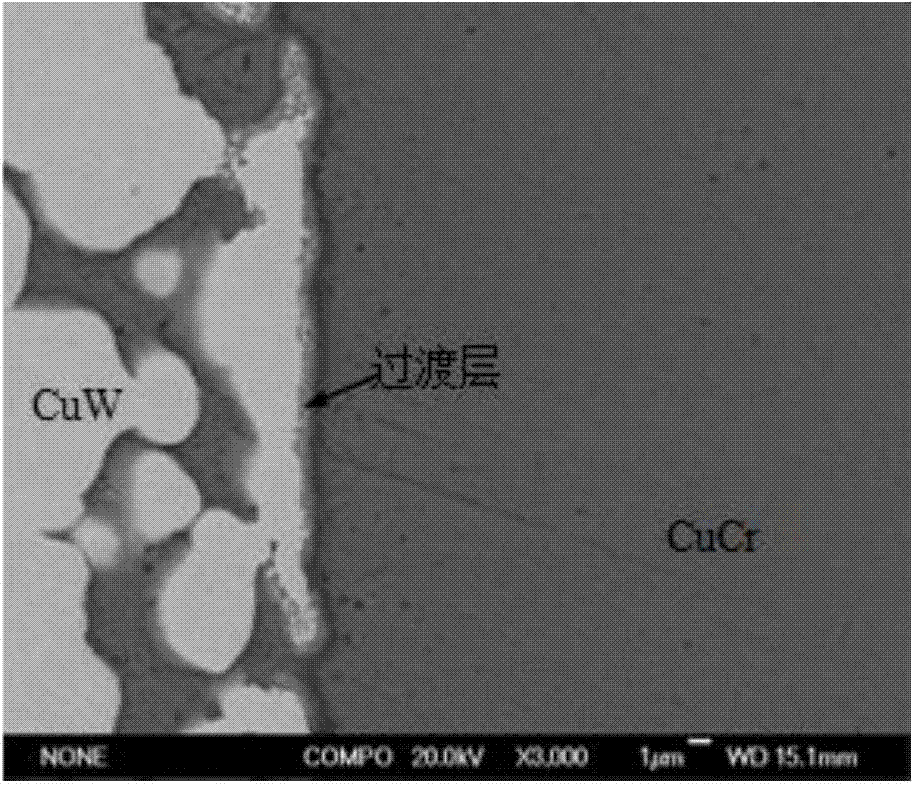

A technology of composite materials and monolithic materials, which is applied in the field of preparation of CuW/CuCr composite materials, can solve the problems of broken CuW ends, shedding, and low bonding strength of CuW/CuCr heterogeneous material interfaces, achieving enhanced bonding force, low cost, The effect of improving the bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

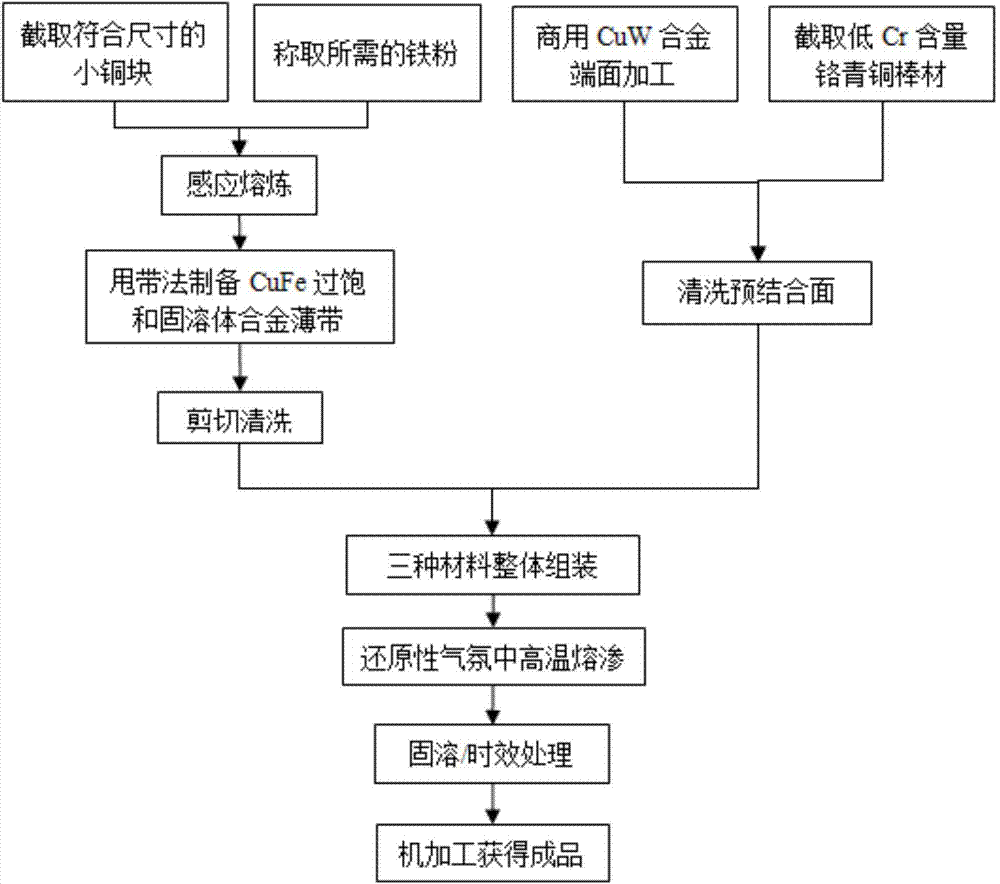

[0036] A kind of preparation method of CuW / CuCr composite material of the present invention, as figure 1 As shown, it specifically includes the following steps:

[0037] Step 1, preparation of CuFe supersaturated solid solution alloy ribbon

[0038] From the purchased pure Cu rod (content 99.99%), cut off small pieces of required quality, clean and remove surface impurities with surfactant, then put the Cu piece in a beaker, inject alcohol into the beaker, when the Cu piece is completely immersed in alcohol , then put the beaker into an ultrasonic cleaner for cleaning for 3-5 minutes and then take it out to dry. Weigh the required amount of pure Fe powder (electrolytic iron powder with a purity of 99.7% and a particle size of 200 mesh), the amount of Fe powder is 2 to 15 wt% of the mass of the Cu block, and put the pure Cu block and Fe powder into the high-purity quartz The crucible was placed in a high-frequency induction furnace, and the inert gas Ar gas was used as the pr...

Embodiment 1

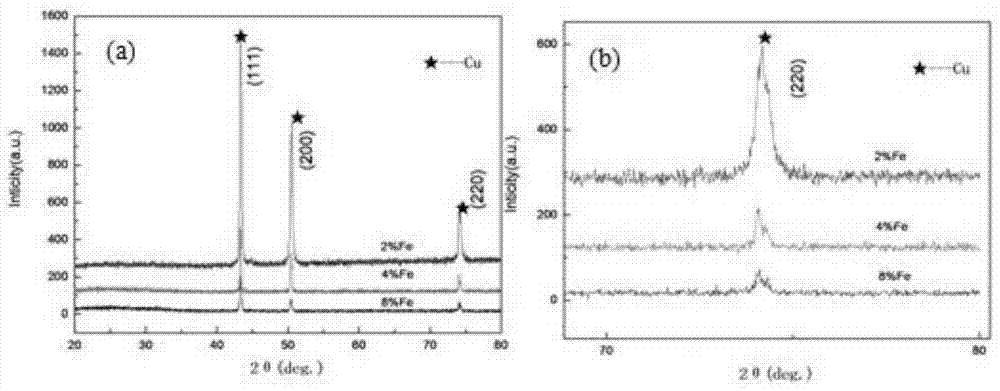

[0053] Step 1, preparation of CuFe supersaturated solid solution alloy ribbon

[0054] From the purchased pure Cu rod (content 99.99%), cut off small pieces of required quality, clean and remove surface impurities with surfactant, then put the Cu piece in a beaker, inject alcohol into the beaker, when the Cu piece is completely immersed in alcohol , then put the beaker into an ultrasonic cleaner for cleaning for 3 minutes and then take it out to dry. Take the pure Fe powder (purity is 99.7% electrolytic iron powder, particle size is 200 meshes) of required content, the amount of Fe powder is 2wt% of the mass of Cu block, pure Cu block and Fe powder are put into high-purity quartz crucible And placed in a high-frequency induction furnace, using the inert gas Ar gas as the protective atmosphere, after repeated smelting at 1200 ° C for 5 times, the CuFe supersaturated solid solution alloy thin strip was prepared by the rapid solidification single-roll stripping method, and its th...

Embodiment 2

[0068] Step 1, preparation of CuFe supersaturated solid solution alloy ribbon

[0069] From the purchased pure Cu rod (content 99.99%), cut off small pieces of required quality, clean and remove surface impurities with surfactant, then put the Cu piece in a beaker, inject alcohol into the beaker, when the Cu piece is completely immersed in alcohol , then put the beaker into an ultrasonic cleaner for cleaning for 4 minutes and then take it out to dry. Take the pure Fe powder (purity is 99.7% electrolytic iron powder, particle size is 200 meshes) of required content by weighing, and the Fe powder consumption is 4wt% of Cu block quality, puts pure Cu block and Fe powder into high-purity quartz crucible And placed in a high-frequency induction furnace, using the inert gas Ar gas as the protective atmosphere, after repeated smelting at 1300 ° C for 3 times, the CuFe supersaturated solid solution alloy thin strip was prepared by the rapid solidification single-roll stripping method,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com