High-strength high-ductility Mg-Ga-Li-series magnesium alloy capable of quickly realizing ageing strengthening and preparation method thereof

A technology of aging strengthening and magnesium alloy, which is applied to the improvement of process efficiency, additive manufacturing, energy efficiency, etc., can solve the problems of aging strengthening effect description, etc., and achieve the effect of high strengthening efficiency and good biocompatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

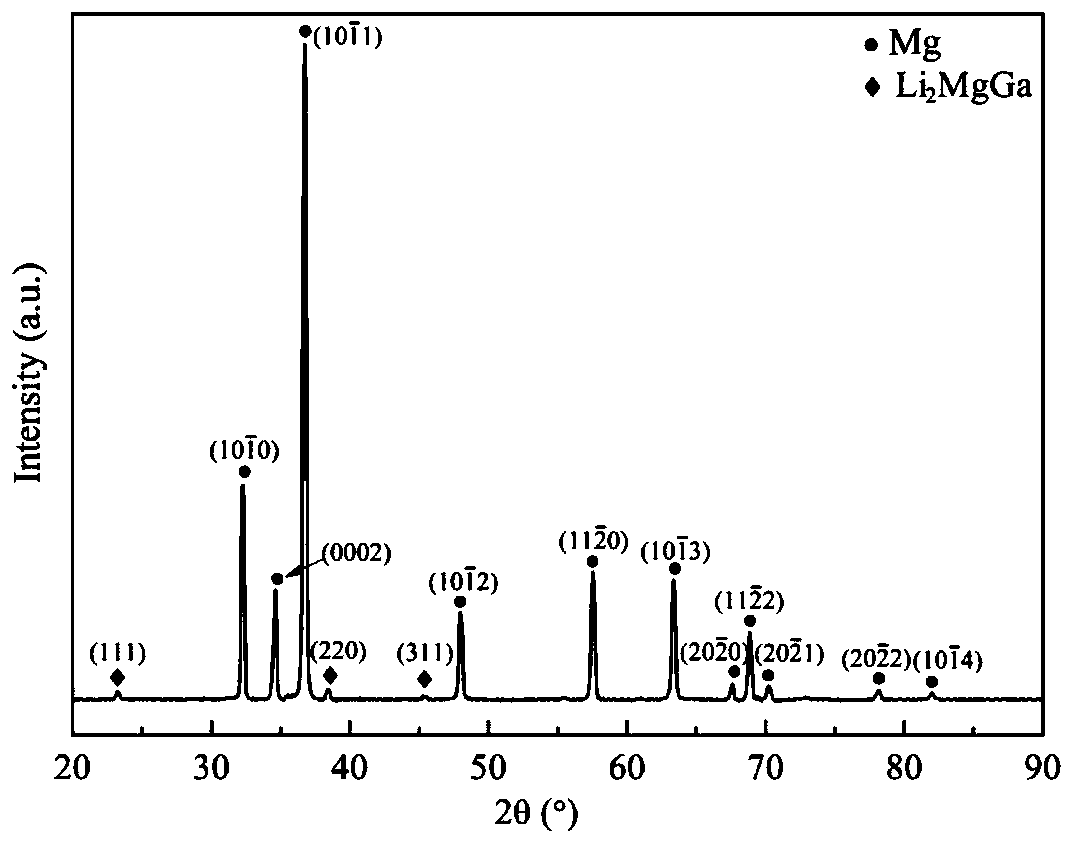

[0036] Embodiment 1: Plastic deformation strengthening of Mg-Ga-Li ternary magnesium alloy

[0037] The process route is as follows: casting → homogenization heat treatment → extrusion → annealing → finished material.

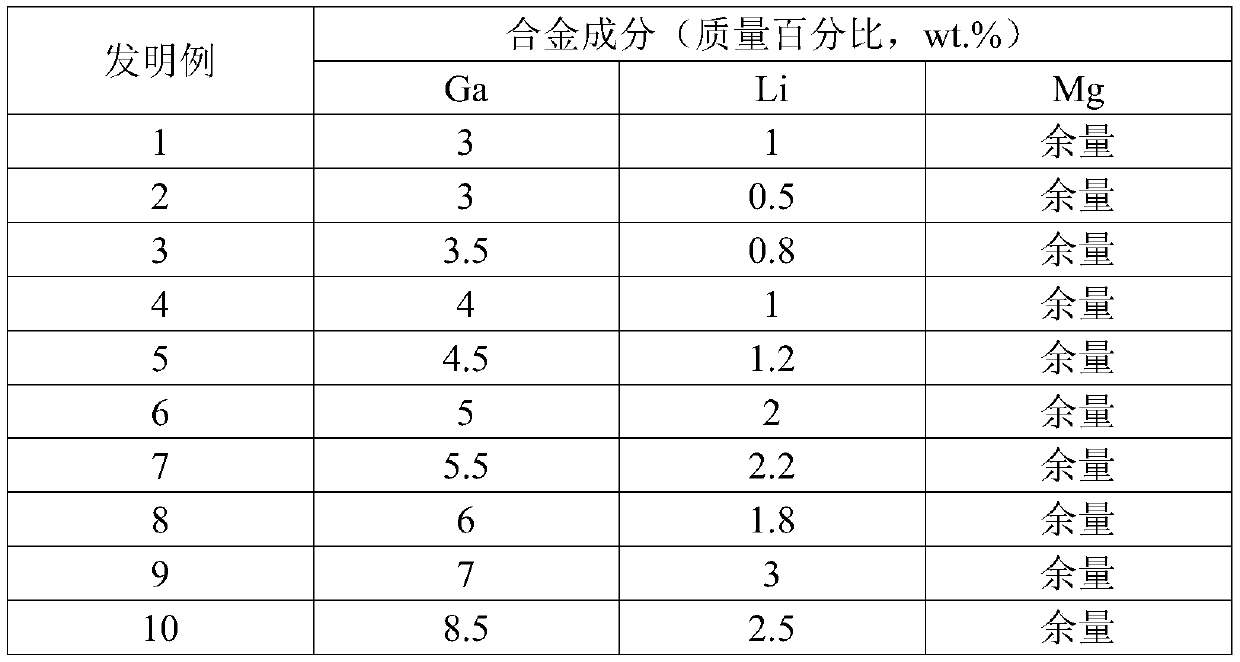

[0038] The compositions of the inventive alloys 1-10 are within the following ranges: the Ga content is 3-8.5%, the Li content is 0.5-3%, and the rest is Mg, as shown in Table 1-1. Inventive example alloys use pure magnesium, pure gallium and Mg-Li intermediate alloys as raw materials, put them into a vacuum induction heating furnace according to the composition ratio of Table 1-1, then vacuumize and feed inert gas, and start to heat up after the air pressure is stable, at 680 Refining at ~750°C for 5-20 minutes, casting, cooling to obtain ingots. Carry out homogenization heat treatment on the slab, and the process system is 250-500 ° C for 1-48 hours. Then squeeze it. The extrusion temperature is 150-450° C., the single-pass extrusion ratio is 10-90, 2-10 p...

Embodiment 2

[0043] Example 2: Rapid aging strengthening of Mg-Ga-Li quaternary magnesium alloy additive manufacturing shaped materials

[0044] The process route is as follows: casting→homogenizing heat treatment→additive manufacturing (3D printing)→rapid aging→finished material.

[0045] The composition of the inventive alloys 11-18 is within the following ranges: the Ga content is 3-8.5%, the Li content is 0.5-3%, and the rest is Mg. On this basis, a trace alloying element is further added, as shown in Table 2 -1 shown. The alloy composition in the table is expressed according to the international practice, and the alloy composition of Invention Example 11 is illustrated, the content of Ga is 3%, the content of Li is 0.8%, the content of Ce is 0.1%, and the balance is Mg. Among them, Mg, Sn and Ce elements are added as pure substances, and Li is added as Mg-Li master alloy. Inventive example alloys described in the table were made into ingots according to the process system in Example...

Embodiment 3

[0050] Example 3: Solid solution rapid aging strengthening of Mg-Ga-Li series quaternary magnesium alloy forged into profiles

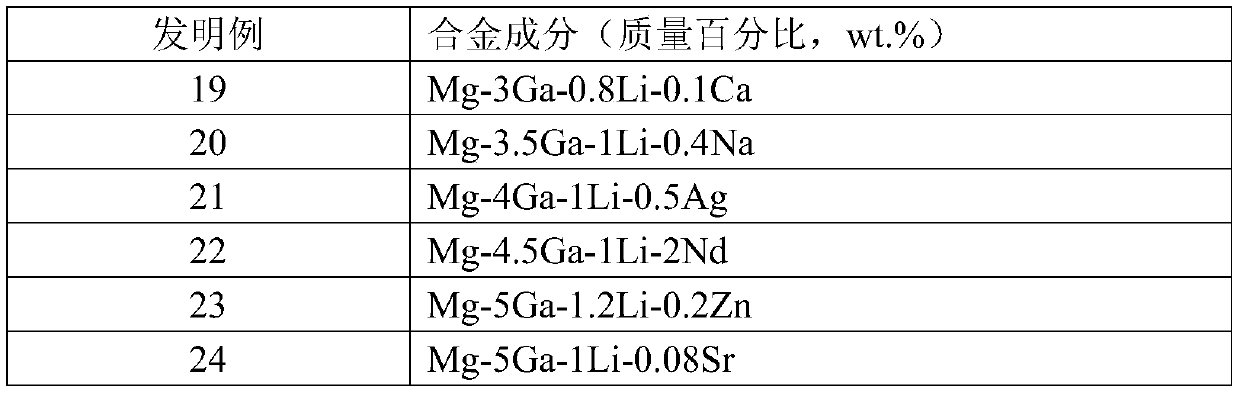

[0051] The process route is as follows: casting→homogenizing heat treatment→forging→solid solution→quenching→rapid aging→finished material.

[0052] The composition of the inventive alloys 19-30 is within the following range: the Ga content is 3-8.5%, the Li content is 0.5-3%, and the rest is Mg. On this basis, a trace alloying element is further added, as shown in Table 3 -1 shown. Except that Li is added as Mg-Li master alloy, other elements are added in the form of pure substances. Inventive example alloys described in the table were made into ingots according to the process system in Example 1 and subjected to homogenization heat treatment. Then forging is carried out, the forging temperature is 250-450° C., and the deformation amount is 10-90%, so as to obtain a forged profile. Then solid solution quenching is carried out, and the process syst...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com