Preparation method of Cr2Nb phase-containing high-strength high-conductivity high-temperature-resistant copper alloy

A technology of copper alloy and high temperature resistance, which is applied in the field of preparation of high-strength, high-conductivity and high-temperature-resistant copper alloys. It can solve problems such as the inability to prepare samples with complex shapes, the inability to apply high-temperature fields, and affect the strengthening effect, so as to improve the effect of dispersion strengthening and high temperature resistance. Excellent performance and easy to generate effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

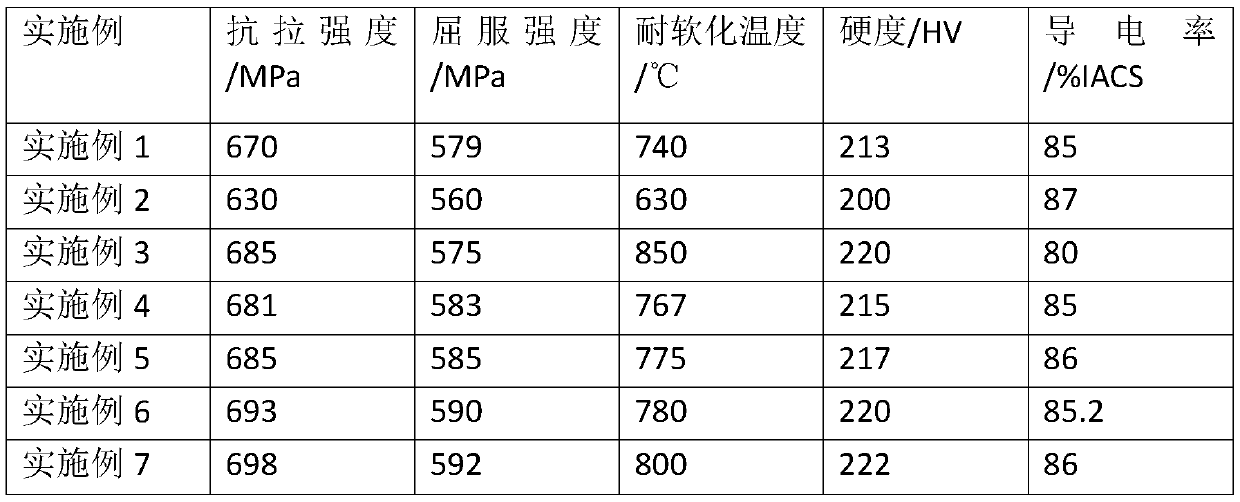

[0037] A method for preparing a high-strength, high-conductivity, high-temperature-resistant copper alloy containing Cr2Nb phase, comprising the following steps:

[0038] (1) Ingredients: Proportioning copper alloy elements is carried out according to the percentage by weight that Cr is 2.2%, Zr content is 0.6%, Nb content is 1.1%, and Cu is the balance, selects and takes corresponding raw materials; Cu is an electrolytic copper plate with a purity of ≥99.990%, Zr is crystalline Zr with a purity of ≥99.9%, Cr is Cr powder with a purity of ≥99.9% and a particle size of 50-90 μm, and Nb is made of a purity of ≥99.5% with a particle size of 10-20μm Nb powder;

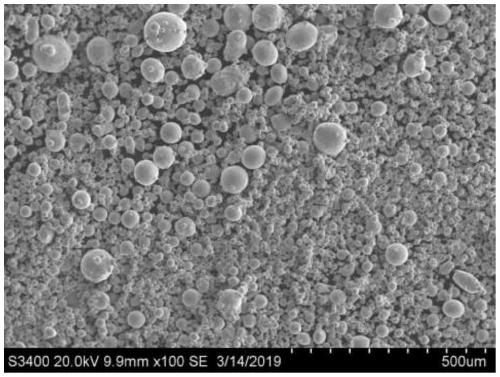

[0039] (2) Atomized powder making: the raw materials are refined and prefabricated into alloy ingots, and the alloy ingots are smelted into alloy liquid by using crucible melting, and then the alloy liquid is passed through the bottom of the tundish by vacuum induction gas atomization method The conduit flows to the atomi...

Embodiment 2

[0044] This embodiment is basically the same as Embodiment 1, the difference is:

[0045] In step (1), the proportioning of copper alloy elements is carried out according to the percentage by weight of 0.6% of Cr, 0.1% of Zr, 0.3% of Nb and Cu as the balance.

[0046] In step (2), electrode induction gas atomization is used for atomization powder production. Under suitable vacuum conditions and protective gas conditions, the refined and prefabricated copper alloy ingots are regionally melted, and the metal liquid flows vertically through the nozzles continuously. The metal liquid is atomized and broken into a large number of fine droplets by the high-pressure airflow through the close-coupled nozzle, and the fine droplets solidify into particles in flight, that is, the Cr 2 Spherical powder of Nb phase.

[0047] The 3D printing in step (3) uses electron beams as energy beams to 3D print the raw materials, the scanning speed of the electron beams is 0.35m / s, and the beam curre...

Embodiment 3

[0049] This embodiment is basically the same as Embodiment 1, the difference is:

[0050] In the step (1), the ingredients are proportioned to the copper alloy elements according to the weight percentages of 4% Cr, 1% Zr, 2% Nb and Cu as the balance.

[0051] The 3D printing in step (3) uses a plasma beam as an energy beam to 3D print the raw material, and the power of the plasma beam is 50kW.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com