7-series aluminum alloy for container and machining process thereof

A processing technology, aluminum alloy technology, applied in the field of 7-series aluminum alloy for containers and its processing technology, can solve problems such as poor strength matching, and achieve the effect of good shape and strength matching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

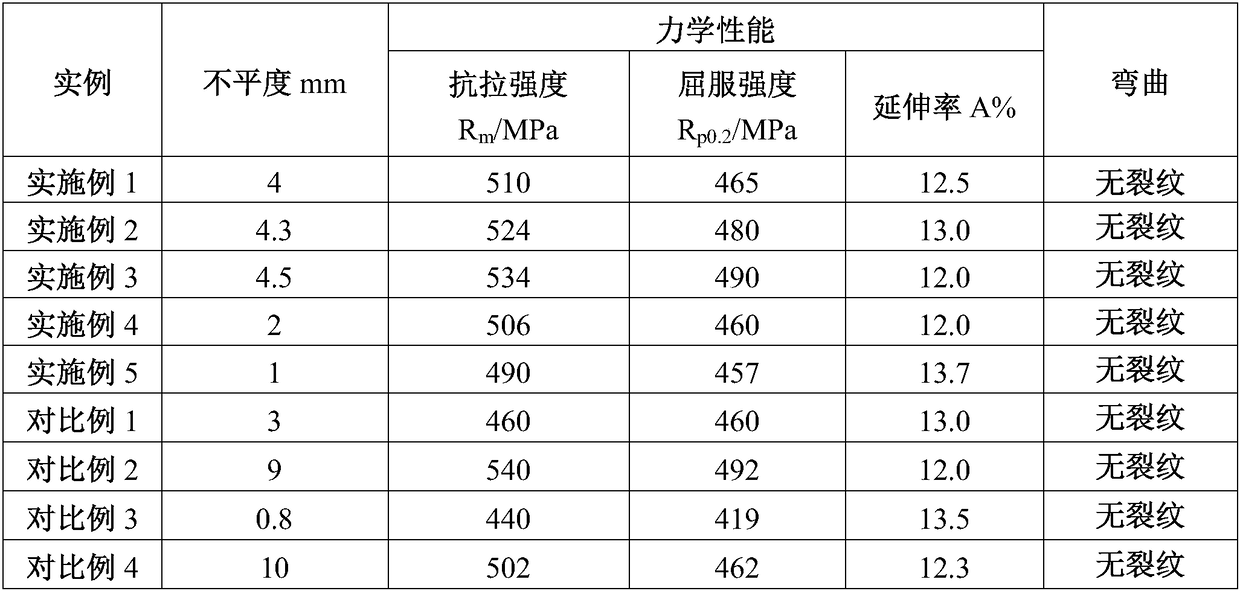

Examples

Embodiment 1

[0024] A processing technology of 7 series aluminum alloys for containers, comprising the steps of:

[0025] A. Prepare 7-series aluminum alloy raw materials according to the following ratios in parts by weight:

[0026] element

Si

Fe

Cu

mn

Mg

Cr

Zn

Ti

Zr

Impurities

Al

content

0.035

0.11

0.006

0.001

1.52

0.001

5.69

0.028

0.10

0.10

margin

[0027] The prepared aluminum alloy raw materials are melted and alloyed in the smelting furnace, and then poured into the holding furnace, refined in the holding furnace, degassed online, and filtered online, and then cast into aluminum alloy ingots. Aluminum alloy melt refining During the process, high-purity chlorine and argon mixed gas are filled into the bottom of the smelting furnace to remove impurity gases in the aluminum alloy melt. The addition of the additive is 0.1% of the weight of the aluminum alloy melt;

[0028] B. Homogenize the a...

Embodiment 2

[0035] A processing technology of 7 series aluminum alloys for containers, comprising the steps of:

[0036] A. Prepare 7-series aluminum alloy raw materials according to the following ratios in parts by weight:

[0037] element

Si

Fe

Cu

mn

Mg

Cr

Zn

Ti

Zr

Impurities

Al

content

0.04

0.12

0023

0.005

1.7

0.002

6.0

0.026

0.14

0.10

margin

[0038] The prepared aluminum alloy raw materials are melted and alloyed in the smelting furnace, and then poured into the holding furnace, refined in the holding furnace, degassed online, and filtered online, and then cast into aluminum alloy ingots. Aluminum alloy melt refining During the process, high-purity nitrogen gas is filled into the bottom of the smelting furnace to remove impurity gases in the aluminum alloy melt. During the casting process of the aluminum alloy melt, an aluminum-titanium-boron wire refiner is added to the launder. The amount...

Embodiment 3

[0046] A processing technology of 7 series aluminum alloys for containers, comprising the steps of:

[0047] A. Prepare 7-series aluminum alloy raw materials according to the following ratios in parts by weight:

[0048] element

Si

Fe

Cu

mn

Mg

Cr

Zn

Ti

Zr

Impurities

Al

content

0.03

0.23

0.003

0.001

1.9

0.002

6.25

0.027

0.13

0.10

margin

[0049] The prepared aluminum alloy raw materials are melted and alloyed in the smelting furnace, and then poured into the holding furnace, refined in the holding furnace, degassed online, and filtered online, and then cast into aluminum alloy ingots. Aluminum alloy melt refining During the process, a mixture of high-purity argon and chlorine gas is filled into the bottom of the melting furnace to remove impurity gases in the aluminum alloy melt. The addition of the additive is 0.1% of the weight of the aluminum alloy melt;

[0050] B. Homogenize the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Roughness | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com