Technological method for refining three-dimensional reconstructed TEM (transmission electron microscope) sample of amorphous solid alloy and evaluation method

A technology for transmission electron microscope samples and three-dimensional reconstruction, which is applied in the preparation of test samples, material analysis using wave/particle radiation, and measurement devices, which can solve the inapplicability and lack of effective technologies for amorphous solid alloy blocks method, no removal and other problems, to achieve the effect of strong manipulability and repeatability, high technical reliability, and easy implementation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] Embodiment 1: adopt amorphous solid alloy Zr 48 Cu 45 A l7 (the subscript number in the chemical formula is at%), the amorphous solid alloy rod is prepared by the vacuum copper mold suction casting method commonly used in this field.

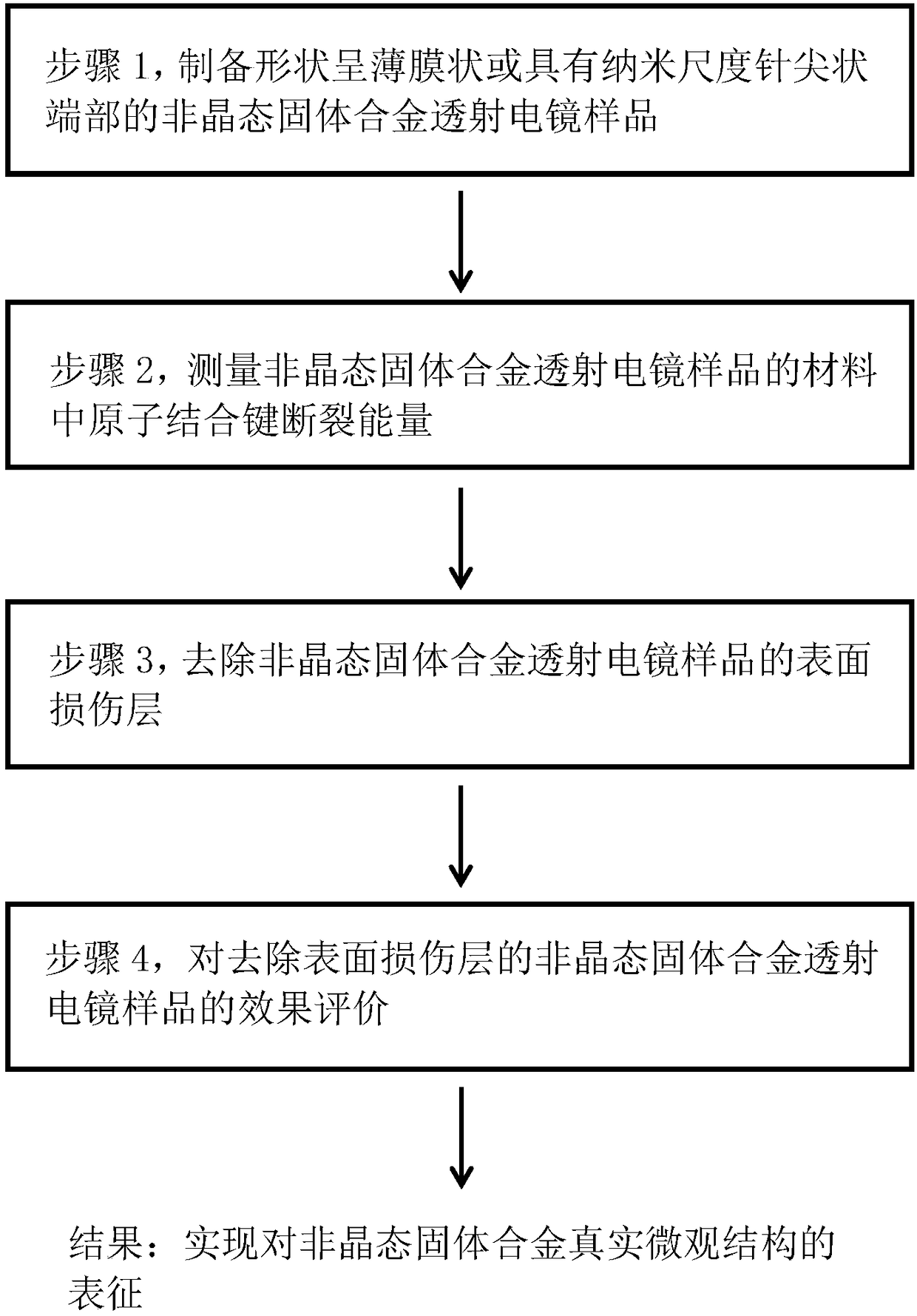

[0049] The specific operation steps of a kind of process method of refining amorphous solid alloy three-dimensional reconstruction transmission electron microscope sample proposed by the present invention are as follows:

[0050] Step 1: Prepare an amorphous solid alloy transmission electron microscope sample in the shape of a film or with a nanoscale needle-like end, including the following sub-steps in turn: (1) Select the temperature of the alloy melt to be 1200 ° C, and use a vacuum copper mold to suction cast The amorphous solid alloy rod was prepared by the method, and the diameter was 1 mm; (2) the amorphous solid alloy rod was cut into short sections with a length of 10 mm by a diamond linear precision cutting machine (South Bay...

Embodiment 2

[0060] Embodiment 2: adopt amorphous solid alloy Fe 78 Si 12 B 10 (the subscript number in the chemical formula is at%), the amorphous solid alloy thin strip is prepared by the rapid planar flow continuous casting method commonly used in this field.

[0061] The specific operation steps of a kind of process method of refining amorphous solid alloy three-dimensional reconstruction transmission electron microscope sample proposed by the present invention are as follows:

[0062]Step 1: Prepare an amorphous solid alloy TEM sample in the shape of a film or with a nanoscale needle-like end, including the following sub-steps in turn: (1) Select the temperature of the alloy melt to be 1200 ° C, and use rapid planar flow continuous casting The amorphous solid alloy thin strip is prepared by the method, the thickness is 32 micrometers, and the width is 20 mm; (2) the amorphous solid alloy thin strip is cut into a disc with a diameter of 3 mm by an ultrasonic cutting machine (Gatan In...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle of incidence | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com