Rare-earth-regulated water-atomized Fe-Cu pre-alloyed powder special for ultra-hard material products and preparation method of rare-earth-regulated water-atomized Fe-Cu pre-alloyed powder

A technology of pre-alloyed powder and super-hard material, which is applied in the field of rare earth-regulated water-atomized Fe-Cu pre-alloy powder for super-hard material products and its preparation, and can solve the problems of poor diamond wettability, poor sharpness, and many impurities. , to improve the density and flexural strength, improve the holding force, and achieve good overall performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

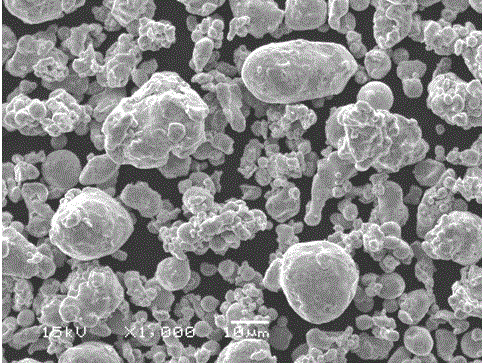

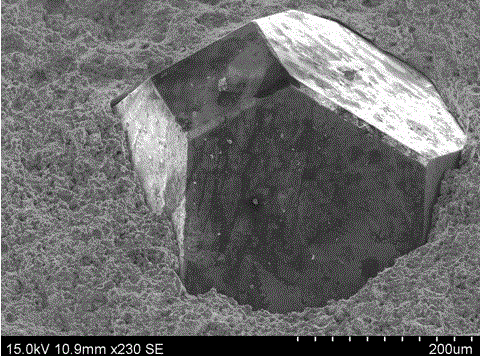

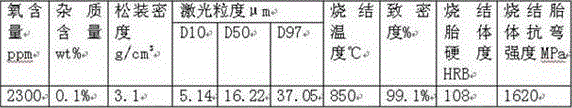

Image

Examples

Embodiment 1

[0016] A medium-frequency induction smelting furnace with a furnace capacity of 250kg for work and production is used as the lining material of magnesia, and the composition ratio is 78.7%Fe, 20%Cu, 1%P, 0.2%Ce, 0.1%Y. The raw materials and their weights are listed in Table 1 below:

[0017] Table 1 Raw materials and weight (embodiment 1)

[0018]

[0019] Add Fe, Cu, CuP, rare earth Ce and Y to the medium frequency induction furnace in turn, energize to melt and refine, deoxidize by adding carbon powder, adjust the superheat of molten steel to 150~200℃, pour it into the tundish, After the molten steel passes through the leakage hole at the bottom of the ladle, it is crushed by high-pressure water and atomized into powder in the atomization barrel filled with nitrogen protection. The powder after atomization is fully dehydrated by vacuum filtration, then put into a drying oven to dry for 6~10 hours, and then reduced with hydrogen-nitrogen mixed gas (hydrogen accounted for ...

Embodiment 2

[0023] A medium-frequency induction smelting furnace with a furnace capacity of 250kg for work and production is used as the lining material of magnesia, and the composition ratio is 78.1%Fe, 20%Cu, 1.5%P, 0.2%Ce, 0.2%Y. The raw materials and their weights are listed in Table 3 below:

[0024] Table 3 raw materials and weight (embodiment 2)

[0025]

[0026] Add Fe, Cu, CuP, rare earth Ce and Y to the medium frequency induction furnace in turn, energize to melt and refine, deoxidize by adding carbon powder, adjust the superheat of molten steel to 150~200℃, pour it into the tundish, After the molten steel passes through the leakage hole at the bottom of the ladle, it is crushed by high-pressure water and atomized into powder in the atomizing barrel filled with nitrogen protection. The powder after atomization is fully dehydrated by vacuum filtration, then put into a drying oven to dry for 6~10 hours, and then reduced with hydrogen-nitrogen mixed gas (hydrogen accounted for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com