A rare earth-adjusted water-atomized Fe-cu pre-alloyed powder for superhard material products and its preparation method

A technology of pre-alloy powder and superhard material, which is applied in the field of rare earth-adjusted water-atomized Fe-Cu pre-alloy powder and its preparation field for superhard material products, which can solve the problems of poor diamond wettability, insufficient holding force, and poor sharpness, etc. problems, to achieve the effect of improving density and bending strength, improving sharpness, and improving holding force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

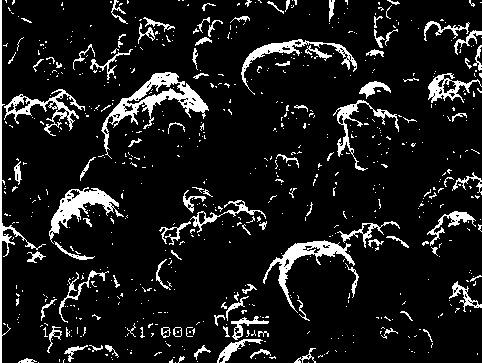

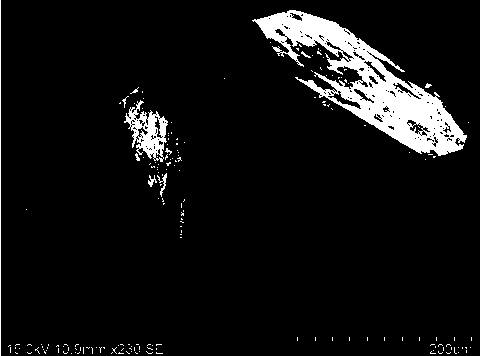

Image

Examples

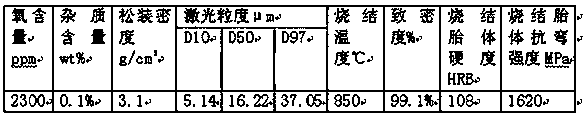

Embodiment 1

[0016] A medium-frequency induction smelting furnace with a furnace capacity of 250kg for work and production is used as the lining material of magnesia, and the composition ratio is 78.7%Fe, 20%Cu, 1%P, 0.2%Ce, 0.1%Y. The raw materials and their weights are listed in Table 1 below:

[0017] Table 1 Raw materials and weight (embodiment 1)

[0018]

[0019] Add Fe, Cu, CuP, rare earth Ce and Y to the medium frequency induction furnace in turn, energize to melt and refine, deoxidize by adding carbon powder, adjust the superheat of molten steel to 150~200℃, pour it into the tundish, After the molten steel passes through the leakage hole at the bottom of the ladle, it is crushed by high-pressure water and atomized into powder in the atomization barrel filled with nitrogen protection. The powder after atomization is fully dehydrated by vacuum filtration, then put into a drying oven to dry for 6~10 hours, and then reduced with hydrogen-nitrogen mixed gas (hydrogen accounted for ...

Embodiment 2

[0023] A medium-frequency induction smelting furnace with a furnace capacity of 250kg for work and production is used as the lining material of magnesia, and the composition ratio is 78.1%Fe, 20%Cu, 1.5%P, 0.2%Ce, 0.2%Y. The raw materials and their weights are listed in Table 3 below:

[0024] Table 3 raw materials and weight (embodiment 2)

[0025]

[0026] Add Fe, Cu, CuP, rare earth Ce and Y to the medium frequency induction furnace in turn, energize to melt and refine, deoxidize by adding carbon powder, adjust the superheat of molten steel to 150~200℃, pour it into the tundish, After the molten steel passes through the leakage hole at the bottom of the ladle, it is crushed by high-pressure water and atomized into powder in the atomization barrel filled with nitrogen protection. The powder after atomization is fully dehydrated by vacuum filtration, then put into a drying oven to dry for 6~10 hours, and then reduced with hydrogen-nitrogen mixed gas (hydrogen accounted fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com