Method for adjusting microstructure of amorphous solid alloy by utilizing configuration and number of melt atomic clusters

A technology of atomic clusters and microstructures, which is applied in the field of metal functional materials preparation, can solve the lack of technical methods for regulating the microstructure of amorphous alloys, the inability to melt atomic cluster structures to solidify amorphous alloys, and the inability to effectively control the amorphous state Alloy microstructure and other issues to achieve the effect of strong manipulability and repeatability, easy implementation, and improved macroscopic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

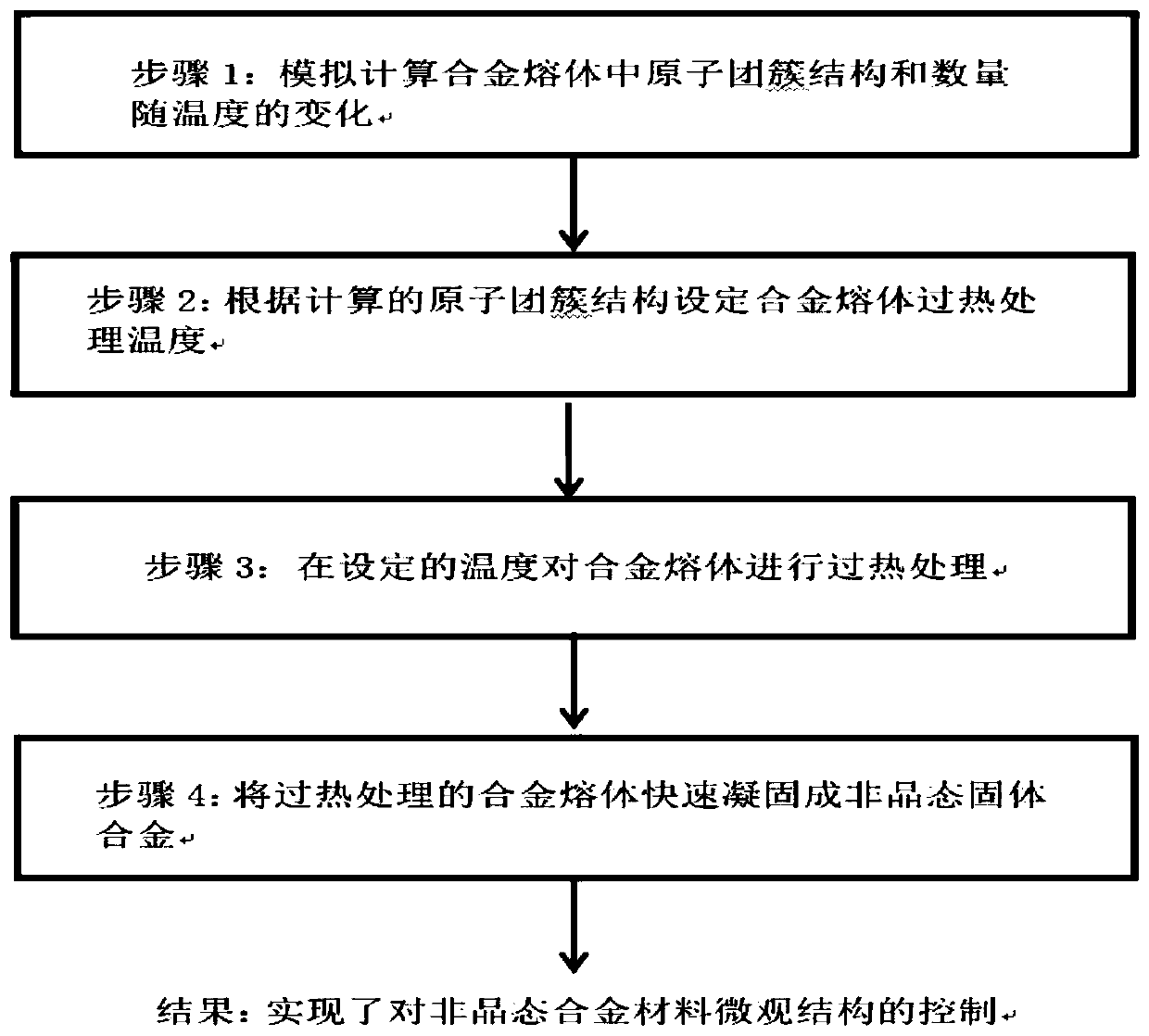

[0036] A process method for adjusting and controlling the microstructure of amorphous solid alloy by using the configuration and quantity of melt atomic clusters, the specific operation steps are as follows:

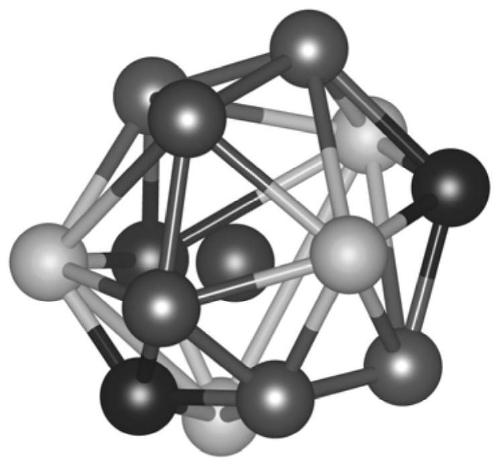

[0037] Step 1. Simulate and calculate the changes in the configuration and number of atomic clusters in the alloy melt with temperature: According to the desired alloy Fe 79 Si 10 B 11 (The subscript number is at%), in the range of 1300-1600℃, calculate the configuration and number of atomic clusters in the alloy melt at different temperatures, and obtain the characteristics of the change of atomic cluster configuration and number with temperature, see Figure 2a , Figure 2b , image 3 , Figure 4a , Figure 4b with Figure 5 ;

[0038] Step 2: Set the alloy melt superheat treatment temperature according to the configuration and number of atomic clusters: According to the calculation results, select the atomic cluster configuration and number of 1600℃, and set the superheat tr...

Embodiment 2

[0043] A process method for adjusting and controlling the microstructure of amorphous solid alloy by using the configuration and quantity of melt atomic clusters, the specific operation steps are as follows:

[0044] Step 1. Simulate and calculate the changes in the configuration and number of atomic clusters in the alloy melt with temperature: According to the desired alloy Fe 79 Si 10 B 11 (The subscript number is at%), in the range of 1300-1600℃, calculate the configuration and number of atomic clusters in the alloy melt at different temperatures, and obtain the characteristics of the change of atomic cluster configuration and number with temperature;

[0045] Step 2: Set the alloy melt superheat treatment temperature according to the configuration and number of atomic clusters: According to the calculation result, select the 1400℃ atomic cluster configuration and quantity, and set the alloy melt superheat treatment temperature to 1400℃;

[0046] Step 3. Heat the alloy melt at the ...

Embodiment 3

[0050] A process method for adjusting and controlling the microstructure of amorphous solid alloy by using the configuration and quantity of melt atomic clusters, the specific operation steps are as follows:

[0051] Step 1. Simulate and calculate the changes in the configuration and number of atomic clusters in the alloy melt with temperature: According to the desired alloy Fe 79 Si 10 B 11 (The subscript number is at%), in the range of 1300-1600℃, calculate the configuration and number of atomic clusters in the alloy melt at different temperatures, and obtain the characteristics of the change of atomic cluster configuration and number with temperature;

[0052] Step 2: Set the alloy melt superheat treatment temperature according to the configuration and number of atomic clusters: According to the calculation result, select the 1300℃ atomic cluster configuration and quantity, and set the alloy melt superheat treatment temperature to 1300℃;

[0053] Step 3. Heat the alloy melt at the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com