Technology for preparing nano-metallic oxide powder with DC (direct-current) plasma method

A nano-metal and oxide powder technology, applied in the direction of tin oxide, nanotechnology, gallium/indium/thallium compounds, etc., can solve the problems of easy agglomeration of nanoparticles, complicated preparation process, environmental pollution, etc., and achieve good particle dispersion, The effect of simple process and high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

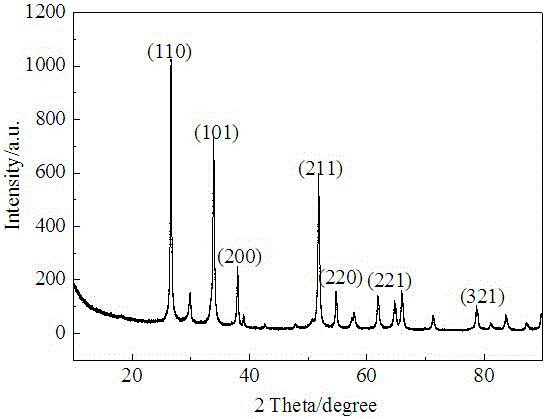

[0025] Preparation of Nano SnO by a Direct Current Plasma Method 2 The powder method, the steps are as follows:

[0026] Take a bulk metal tin ingot (purity >99.99%), put it into a melting furnace, heat and melt it to 600°C, and keep it warm for 1h. Connect the catheter, and electromagnetically heat the catheter to 650°C and keep it warm.

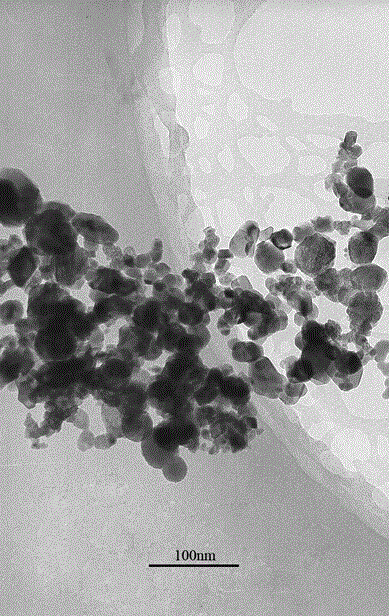

[0027] Vacuum the reaction chamber to 10 -2 MPa, filled with cooling air at 10-20°C, and cooling water is passed into the interlayer of the reactor. Turn on the power supply of the arc plasma gasification system, adjust the gasification current of the reactor to 10-2000A, and the voltage to 5-400V. Introduce argon gas into the tin melting furnace to form a stable melt jet and start the gasification reaction. The gasification of tin liquid under the action of high temperature plasma in the reaction and the O in the air 2 React, form atomic clusters, and aggregate into SnO 2 Nanoparticles settle into the collection chamber with the cold...

Embodiment 2

[0031] Preparation of Nano-In by a DC Plasma Method 2 o 3 The powder method, the steps are as follows:

[0032] Take the bulk metal indium ingot (purity >99.99%), put it into the melting furnace, heat and melt it to 300°C, and keep it warm for 1h. Connect the catheter, and electromagnetically heat the catheter to 400°C and keep it warm.

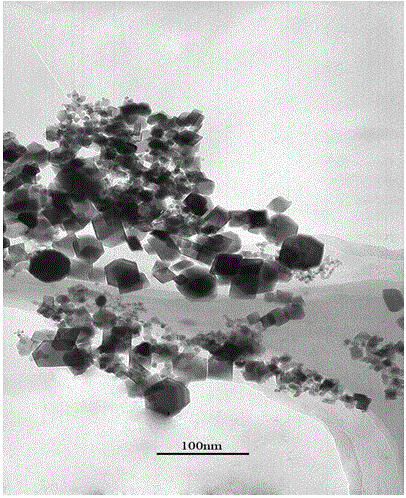

[0033] Vacuum the reaction chamber to 10 -2 MPa, filled with cooling air at 10-20°C, and cooling water is passed into the interlayer of the reactor. Turn on the power supply of the arc plasma gasification system, adjust the gasification current of the reactor to 10-2000A, and the voltage to 5-400V. Pass argon gas into the indium melting furnace to form a stable melt jet and start the gasification reaction. Gasification of liquid indium under the action of high-temperature plasma in the reaction and O in the air 2 React, form atomic clusters, and aggregate into In 2 o 3 Nanoparticles settle into the collection chamber with the cold win...

Embodiment 3

[0037] The process for preparing nano metal oxide powder by DC plasma method comprises the following steps:

[0038] Step 1. Put the block high-purity metal indium into the melting furnace, melt it at 600°C, and keep it warm for 1 hour to obtain a metal melt; electromagnetically heat the catheter connected to the furnace, and heat the catheter to 650°C. maintain that temperature;

[0039] Step 2. Vacuumize the reaction chamber to 10MPa, fill it with cooling air at 20°C, and pass cooling water into the interlayer of the reactor placed in the reaction chamber;

[0040] Step 3. Turn on the power supply of the arc plasma gasification system of the reactor, adjust the gasification current to 2000A, and the voltage to 400V;

[0041] Step 4. Pass inert gas into the molten metal in the melting furnace in step 1, drain it with a catheter, pass it into the reactor, and carry out gasification reaction to form a metal jet;

[0042] Step 5. The metal jet is gasified under the action of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com