Method for preparing powder material with electrochemical cathode

A powder material and electrochemical technology, which is applied in the field of electrochemical cathode preparation of powder materials, can solve the problems of high cost, complicated process, and low output.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Embodiment 1: Cathodic corrosion of metal tin in ionic liquid prepares nano-tin powder

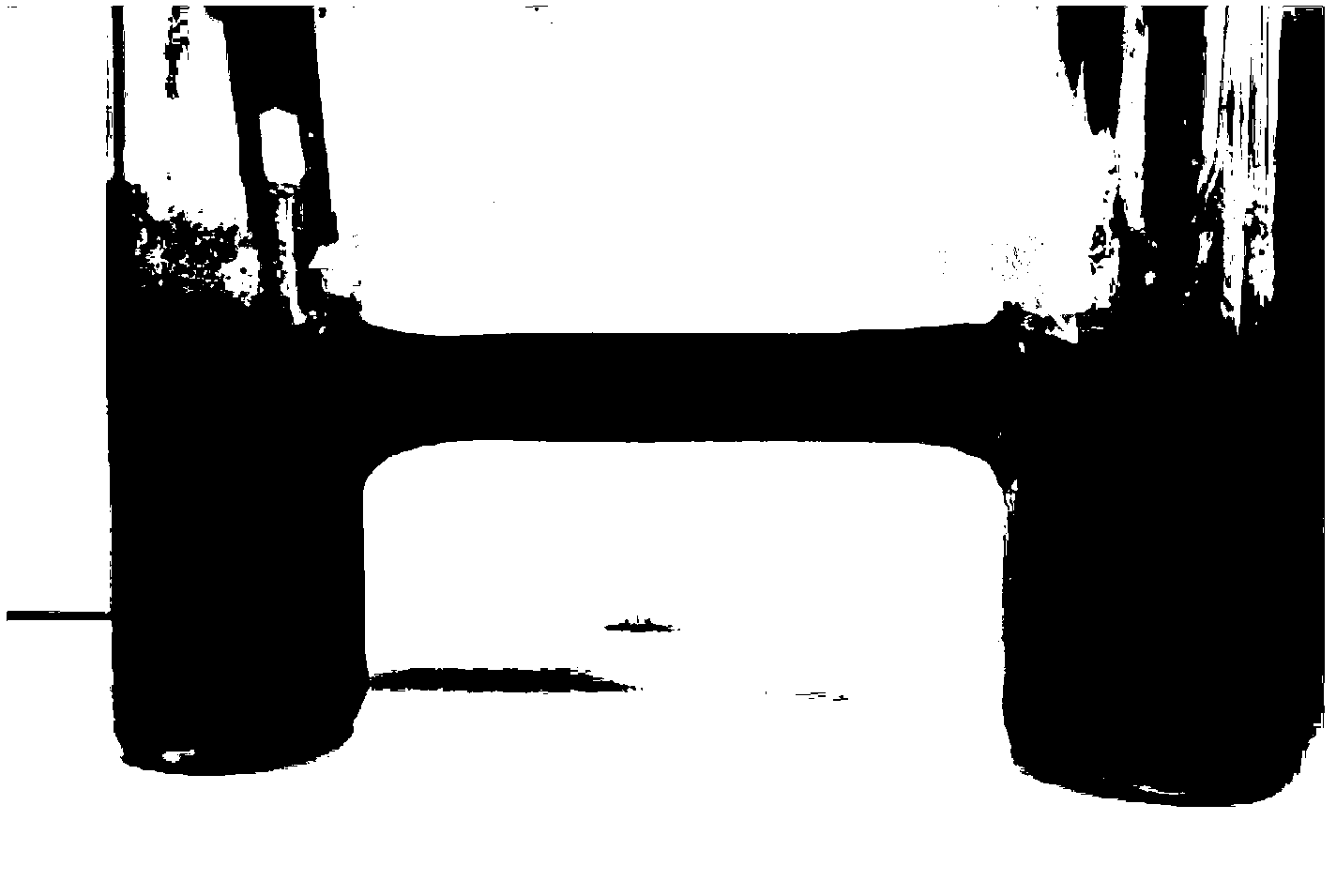

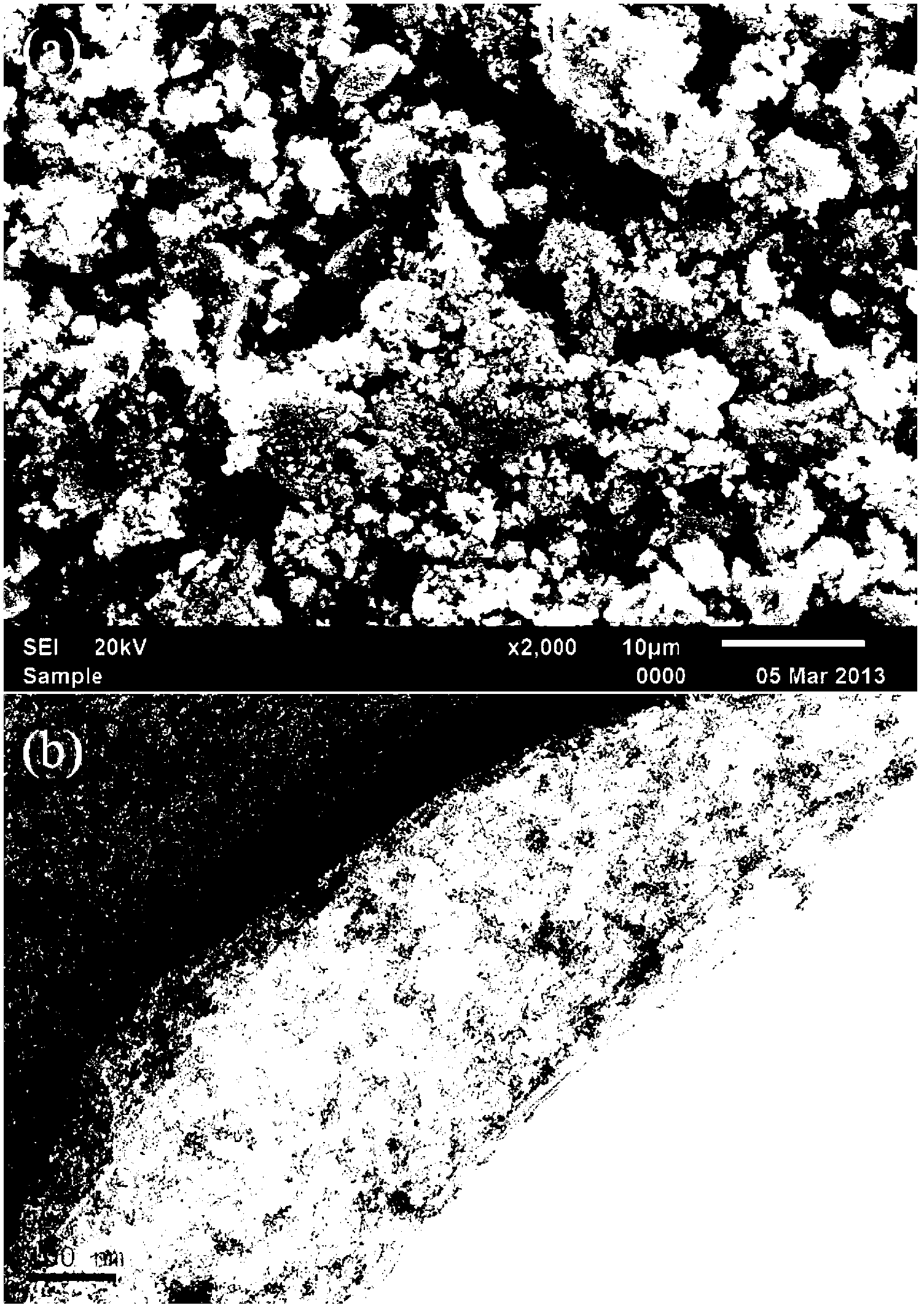

[0039] Such as device figure 1 As shown, the Pt sheet is used as the anode, the Sn rod is used as the cathode, and the ionic liquid 1-n-butyl-1-methylpyrrolidine bis(trifluoromethylsulfonyl)imide is used as the electrolyte, and the constant voltage is –20V The cathode was polarized for 6 hours, and then the product obtained from the cathode was washed 6 times with absolute ethanol, ultrasonically dispersed (80W, 30kHz, 1min), centrifuged at a high speed of 13300 rpm, and finally the product was vacuum-dried at 40°C to obtain tin powder. figure 2 Scanning electron microscope (SEM) and transmission electron microscope (TEM) images of the prepared Sn powder material. Obviously, the prepared tin powder is nano tin powder.

Embodiment 2

[0040] Example 2: Prepare nano-tin powder by corroding a tin rod at cathode-25V in tetraethylammonium hexafluorophosphate solution

[0041]With the Pt sheet as the anode and the Sn rod as the cathode, in a DMF solution of 0.5mol / L tetrabutylammonium hexafluorophosphate, the constant voltage -25V strong cathodic polarization for 12h, and then the product obtained from the cathode was washed with absolute ethanol for 6 Second, ultrasonic dispersion (80W, 30kHz, 1min), high-speed centrifugation at 12,000 rpm, and finally the product was vacuum-dried at 50°C to obtain tin powder. TEM ( image 3 ) shows that the prepared tin powder is nano-tin powder with a uniform particle size of about 5nm.

Embodiment 3

[0042] Example 3: Preparation of Nano Antimony Powder by Cathode-25V Corrosion Antimony Rod in Tetraethylammonium Hexafluorophosphate Solution

[0043] With the Pt sheet as the anode and the Sb rod as the cathode, in a DMF solution of 0.5mol / L tetrabutylammonium hexafluorophosphate, a constant voltage of -25V was used for strong cathodic polarization for 12 hours, and then the product obtained from the cathode was washed with absolute ethanol for 6 Second, ultrasonic dispersion (80W, 30kHz, 1min), high-speed centrifugation at 12,000 rpm, and finally the product was vacuum-dried at 50°C to obtain antimony powder. TEM ( Figure 4 ) shows that the prepared antimony powder is nano-antimony powder with uniform particle size of about 15nm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com