Preparation method of thorn-shaped or petal-shaped rough-surface gold-silver alloy nanometer material

A gold-silver alloy and nano-material technology, which is applied in the field of preparation of gold-silver alloy nano-materials with thorny and petal-like rough surfaces, can solve the problems of inconvenient mass production, low shape controllability, and complicated preparation process, and achieve It is convenient to load and modify a large number of organic compounds, the equipment is simple and easy to operate, and the effect of low reaction temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

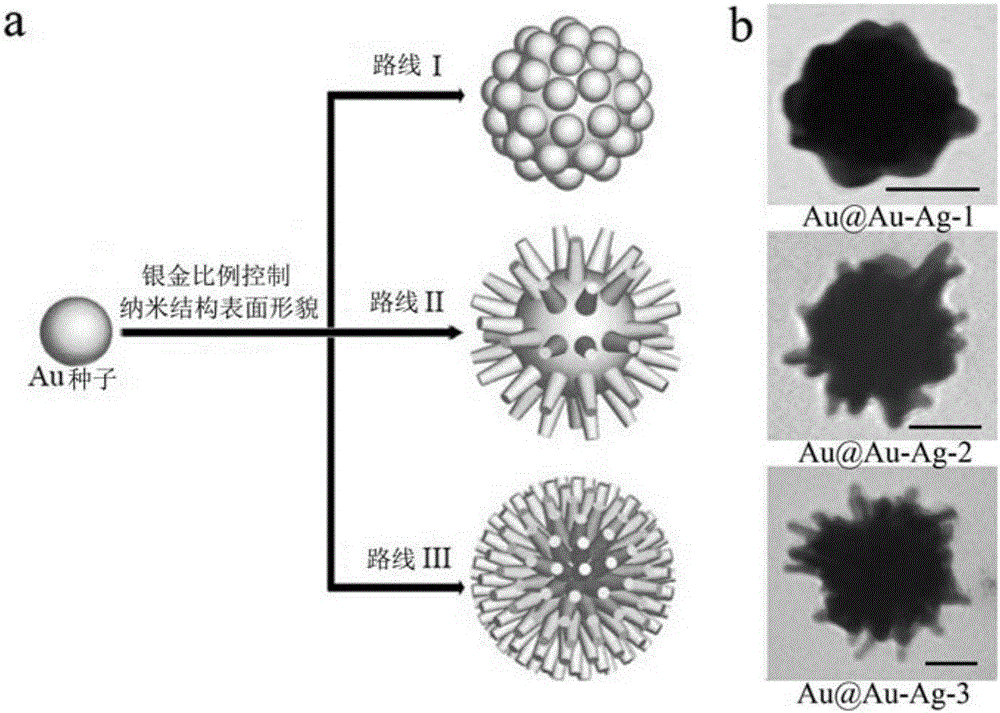

[0035]Example 1 Preparation of petal-shaped gold-silver alloy nanoparticles (Au@Au-Ag-1).

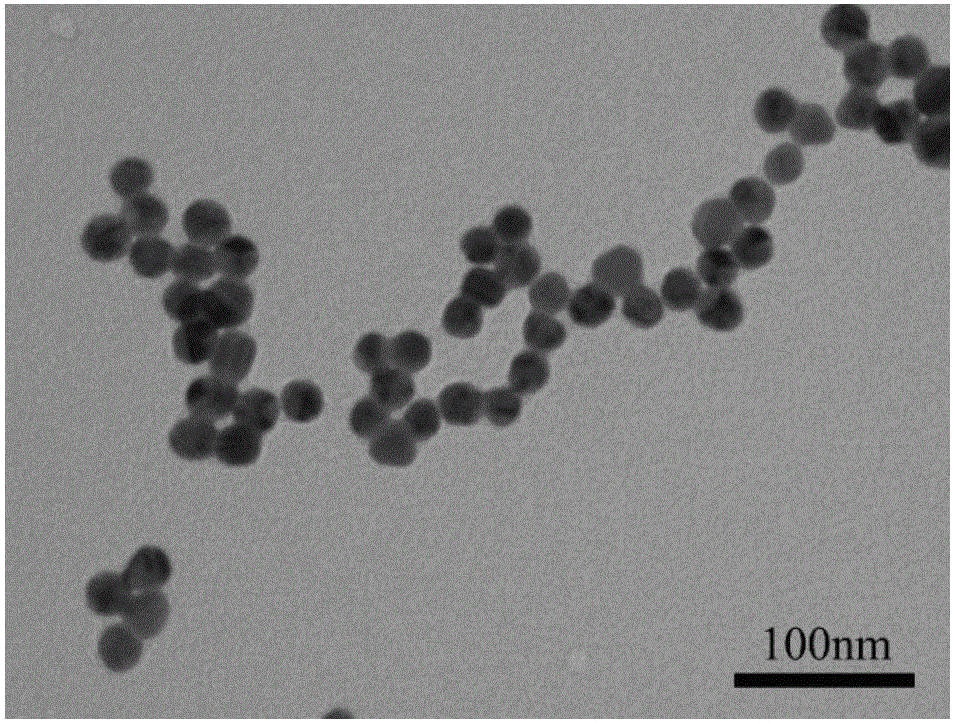

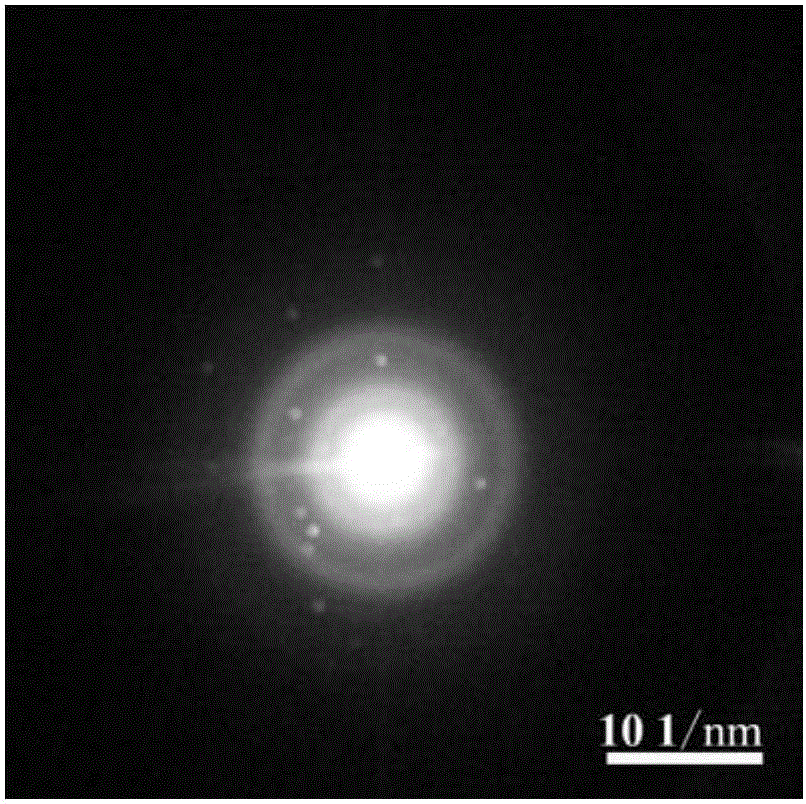

[0036] 1) Heat a mixture of 0.8 mL of 1% chloroauric acid aqueous solution and 79.2 mL of deionized water in an oil bath to 130° C., then add 2.8 mL of 1% trisodium citrate aqueous solution (prepared now) ), continue to stir at 130°C for 20min, turn off the heat source, and cool to room temperature to obtain gold nanoparticles with a concentration of 0.73nM. They are washed by centrifugation with deionized water, resuspended with deionized water after washing, and the concentration of gold nanoparticles is kept constant. Change, promptly obtain gold nanoparticle seed solution, standby, the prepared gold nanoparticle average particle size is 20nm, as figure 2 , image 3 shown.

[0037] 2) Mix 1.2mL of 10mM chloroauric acid aqueous solution with 3.6mL of deionized water, place in a 10°C environment (water bath) and keep stirring for 10min.

[0038] 3) After step 2), add 2.4 μL of 10 m...

example 2

[0039] Example 2 Prepare spiny gold-silver alloy nanoparticles (Au@Au-Ag-3).

[0040] 1) Heat a mixture of 0.8 mL of 1% chloroauric acid aqueous solution and 79.2 mL of deionized water in an oil bath to 130° C., then add 2.8 mL of 1% trisodium citrate aqueous solution (prepared now) ), continue to stir at 130°C for 20min, turn off the heat source, and cool to room temperature to obtain gold nanoparticles with a concentration of 0.73nM. They are washed by centrifugation with deionized water, resuspended with deionized water after washing, and the concentration of gold nanoparticles is kept constant. Change, promptly obtain gold nanoparticle seed solution, standby, the prepared gold nanoparticle average particle size is 20nm, as figure 2 , image 3 shown.

[0041] 2) Mix 1.2mL of 10mM chloroauric acid aqueous solution with 3.6mL of deionized water, place in a 10°C environment (water bath) and keep stirring for 10min.

[0042] After step 2), add 96μL 10mM silver nitrate aqueo...

example 3

[0043] Example 3 Prepare spiny gold-silver alloy nanoparticles (Au@Au-Ag-3).

[0044] 1) Heat a mixture of 0.8 mL of 1% chloroauric acid aqueous solution and 79.2 mL of deionized water in an oil bath to 130° C., then add 2.8 mL of 1% trisodium citrate aqueous solution (prepared now) ), continue to stir at 130°C for 20min, turn off the heat source, and cool to room temperature to obtain gold nanoparticles with a concentration of 0.73nM. They are washed by centrifugation with deionized water, resuspended with deionized water after washing, and the concentration of gold nanoparticles is kept constant. Change, promptly obtain gold nanoparticle seed solution, standby, the prepared gold nanoparticle average particle size is 20nm, as figure 2 , image 3 shown.

[0045] 2) Mix 1.2mL of 10mM chloroauric acid aqueous solution with 3.6mL of deionized water, place in a 10°C environment (water bath) and keep stirring for 10min.

[0046] 3) After step 2), add 96μL of 10mM silver nitrate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average diameter | aaaaa | aaaaa |

| Mean radius | aaaaa | aaaaa |

| The average diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com