Preparation method of nitrogen-doped carbon-supported monoatomic catalyst

A nitrogen-doped carbon and catalyst technology, which is applied in the direction of catalyst activation/preparation, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of complexity and cumbersome preparation process, and achieve simple operation and suitable for large-scale production Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Step 1: Under stirring, dissolve copper acetate in deionized water to obtain a colored and transparent solution A with a concentration of 0.01mol / L, and then use a micro-injector to add the colored and transparent solution A drop by drop to the colored and transparent solution A with a volume of 5‰ The pyrrole monomer, continued magnetic stirring for 1h to obtain the reaction precursor;

[0026] Step 2: Transfer the reaction precursor to a polytetrafluoroethylene-lined stainless steel reactor with a filling ratio of 30% and conduct a hydrothermal reaction at 80°C for 5 hours. After the reaction, the product is centrifuged and then freeze-dried at -10°C ;

[0027] Step 3: Add the dried sample to an aqueous hydrochloric acid solution with a concentration of 1 mol / L, stir at room temperature for 1 hour to remove oxides, separate by suction filtration and wash, and then freeze-dry at -10°C;

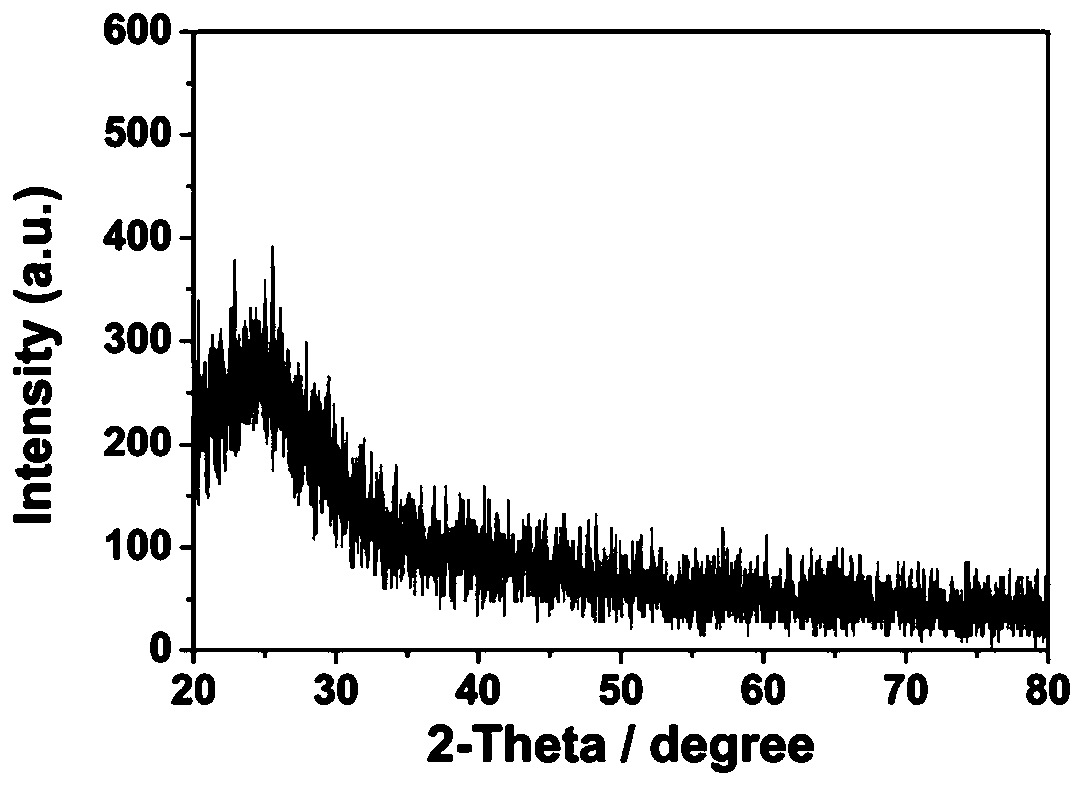

[0028] Step 4: Put the sample dried in Step 3 in a porcelain boat, and heat it in...

Embodiment 2

[0030] Step 1: Under stirring, dissolve nickel acetate in deionized water to obtain a colored and transparent solution A with a concentration of 0.03mol / L, and then use a micro-injector to add the colored and transparent solution A drop by drop to the colored and transparent solution A with a volume of 10‰ The pyrrole monomer, continuous mechanical stirring for 8h to obtain the reaction precursor;

[0031] Step 2: Transfer the reaction precursor to a polytetrafluoroethylene-lined stainless steel reactor with a filling ratio of 40% and conduct a hydrothermal reaction at 100°C for 10 hours. After the reaction, the product is centrifuged and then freeze-dried at -80°C ;

[0032] Step 3: Add the dried sample to an aqueous hydrochloric acid solution with a concentration of 3 mol / L, stir at room temperature for 5 hours to remove oxides, separate by suction filtration and wash, then freeze-dry at -80°C;

[0033] Step 4: Place the sample dried in Step 3 in a porcelain boat, and heat ...

Embodiment 3

[0035] Step 1: Under stirring, dissolve cobalt acetate in deionized water to obtain a colored and transparent solution A with a concentration of 0.05mol / L, and then add the colored and transparent solution A to the colored and transparent solution A dropwise using a micro-injector with a volume of 8‰ The pyrrole monomer, continued magnetic stirring for 10h to obtain the reaction precursor;

[0036] Step 2: Transfer the reaction precursor to a polytetrafluoroethylene-lined stainless steel reactor at a filling ratio of 50% and conduct a hydrothermal reaction at 120°C for 12 hours. After the reaction, the product is centrifuged and then freeze-dried at -50°C ;

[0037] Step 3: Add the dried sample to an aqueous hydrochloric acid solution with a concentration of 5 mol / L, stir at room temperature for 10 h to remove oxides, separate and wash by suction, and then freeze-dry at -50°C;

[0038] Step 4: Place the sample dried in Step 3 in a porcelain boat, heat-treat in a tube furnace ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com