Natural cellulose substrate composite material modified by MOFs nanoparticles and preparation method thereof

A natural cellulose and nanoparticle technology, applied in the field of natural cellulose-based composite materials and its preparation, can solve the problems of low porosity, poor mechanical properties, etc., and achieve high porous structure and specific surface area, low density, and environmentally friendly Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

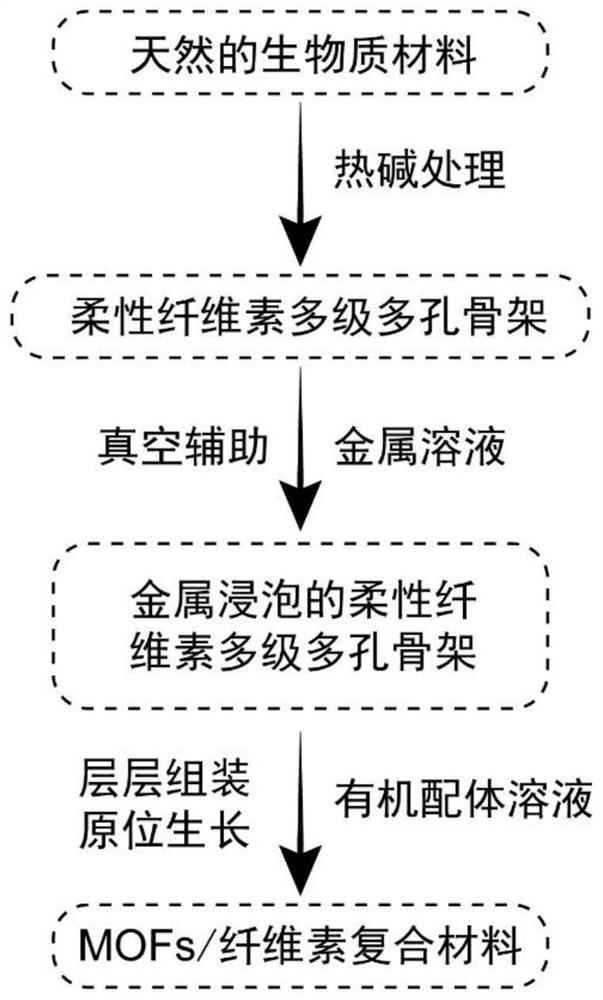

[0035] The present invention provides a kind of preparation method of the natural cellulose substrate composite material of MOFs nano particle modification, comprises the following steps:

[0036] The biomass material is chemically pretreated in an alkaline solution to obtain a flexible cellulose hierarchical porous material;

[0037] Under vacuum assistance, the flexible cellulose multi-level porous material is ion-exchanged in a metal salt solution, then an organic ligand solution is added for in-situ growth, and the above ion-exchange and in-situ growth processes are repeated for layer-by-layer assembly. The natural cellulose substrate composite material modified by the MOFs nanoparticles is obtained.

[0038] In the present invention, unless otherwise specified, all preparation materials are commercially available products well known to those skilled in the art.

[0039] In the invention, the biomass material is chemically pretreated in an alkaline solution to obtain a fl...

Embodiment 1

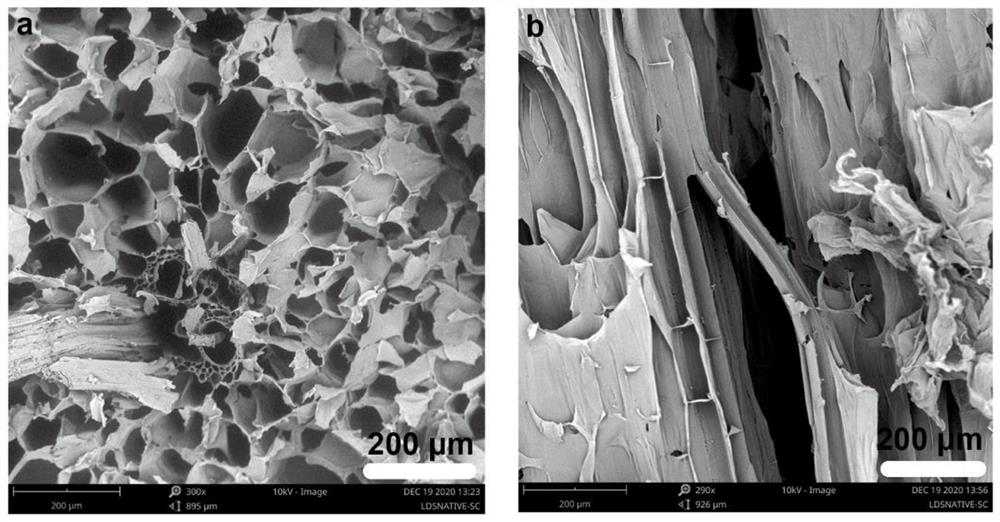

[0060] Place sugarcane in 1.0mol / L sodium hydroxide solution, chemically pretreat at 90°C for 12 hours, wash, and freeze-dry to obtain a flexible cellulose hierarchical porous material;

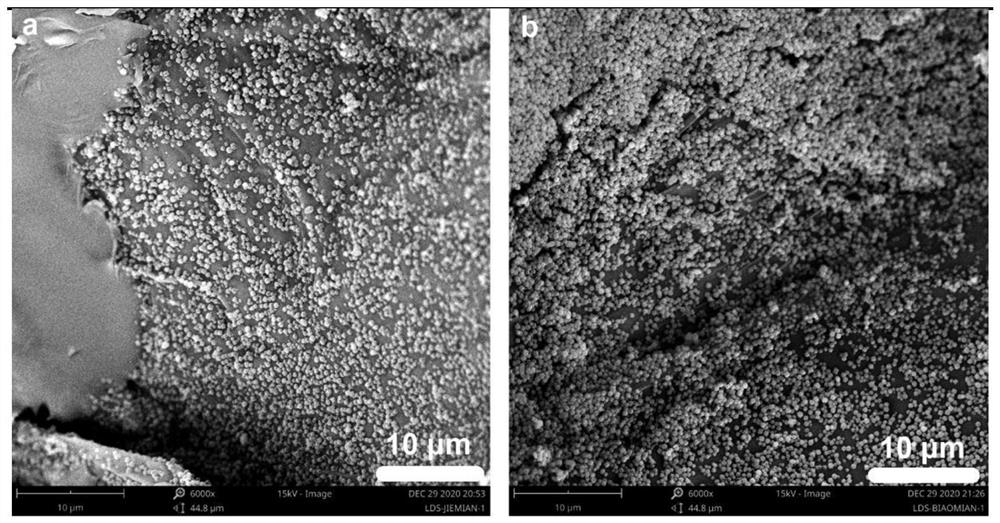

[0061] Under vacuum assistance (vacuum degree: 0.08MPa), 0.25g of the flexible cellulose multi-level porous material was immersed in 40mL of cobalt nitrate solution with a concentration of 0.04mol / L. After ion exchange at room temperature for 2h, 40mL of 0.16 The 2-methylimidazole coordination solution (solvent is anhydrous methanol) of mol / L, reacts 24h, obtains the natural cellulose substrate composite material (the natural cellulose substrate composite material modified by the MOFs nanoparticle modification of described MOFs nanoparticle) It is a three-dimensional network channel structure with an apparent density of 0.075g / cm 3 , the pore volume is 0.059cm 3 / g, MOFs nanoparticles are ZIF-67, particle diameter is 700nm, and the load capacity of described ZIF-67 is 3.5wt%).

Embodiment 2

[0063] Place sugarcane in 1.0mol / L sodium hydroxide solution, chemically pretreat at 90°C for 12 hours, wash, and freeze-dry to obtain a flexible cellulose hierarchical porous material;

[0064] Under vacuum assistance (vacuum degree: 0.08MPa), 0.25g of the flexible cellulose multi-level porous material was immersed in 40mL of cobalt nitrate solution with a concentration of 0.04mol / L. After ion exchange at room temperature for 2h, 40mL of 0.16 mol / L 2-methylimidazole solution (solvent is anhydrous methanol), reacted for 24h, repeated the above-mentioned ion exchange and in-situ growth process to carry out layer-by-layer assembly twice, and obtained the natural cellulose modified by the MOFs nanoparticles Substrate composite material (the natural cellulose substrate composite material modified by the MOFs nanoparticles is a three-dimensional network pore structure, and the apparent density is 0.081g / cm 3 , the pore volume is 0.129cm 3 / g, the MOFs nanoparticles are ZIF-67, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com