Titanium surface preparation batio 3 /tio 2 Methods of Piezoelectric Antimicrobial Coatings

An antibacterial coating and piezoelectric technology, applied in the field of metal surface coating, can solve the problems of easy corrosion, endangering the ecological environment, non-wear resistance, etc., and achieve the effects of high production efficiency, simple preparation process and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] This example provides a method for preparing BaTiO on the surface of a titanium substrate 3 / TiO 2 The method of piezoelectric antibacterial coating, the steps are as follows:

[0045] (1) The titanium matrix TA1 (its chemical composition is (wt.%), Fe: 0.03-0.05%, C: 0.08%, N: 0.03%, H: 0.014-0.018%, O: 0.015-0.018%, the rest For Ti (≥99.8wt.% purity)), cut it into a square sample of 50×50×0.5mm, then use 180#, 360#, 800# and 1200# sandpaper to grind and polish step by step, and then the polished titanium substrates were respectively Ultrasonic cleaning was performed for 10 min in acetone, ethanol and pure water to obtain pretreated titanium samples, which were then dried in cold air for later use;

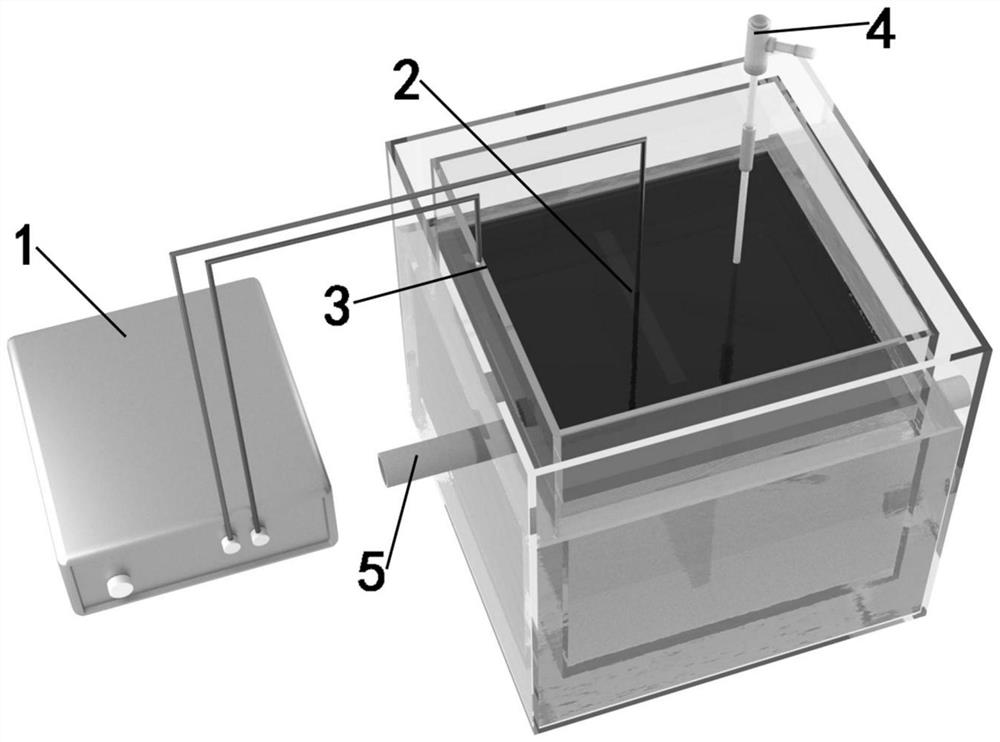

[0046] (2) The pretreated titanium sample obtained in step (1) was immersed through a wire to contain 0.014mol / L Na 2 SiO 3 ·9H 2 O, 0.017mol / L (NaPO 3 ) 6 and 0.026mol / L BaTiO 3 Powder (particle size less than 3μm) in the electrolyte (prepared the above chemical r...

Embodiment 2

[0054] This example provides a method for preparing BaTiO on the surface of a titanium substrate 3 / TiO 2 The method of piezoelectric antibacterial coating, the steps are basically the same as in Example 1, the difference is only: in this experimental example, in step (3), in order to improve the surface roughness of the micro-arc oxidation coating, the micro-arc oxidation voltage output For positive and negative pulses, the positive pulse voltage is 500V, the negative pulse voltage is 60V, the frequency is 600Hz, the positive pulse duty cycle is 20%, the negative pulse duty cycle is 10%, and the number ratio of positive and negative pulses is 4:1.

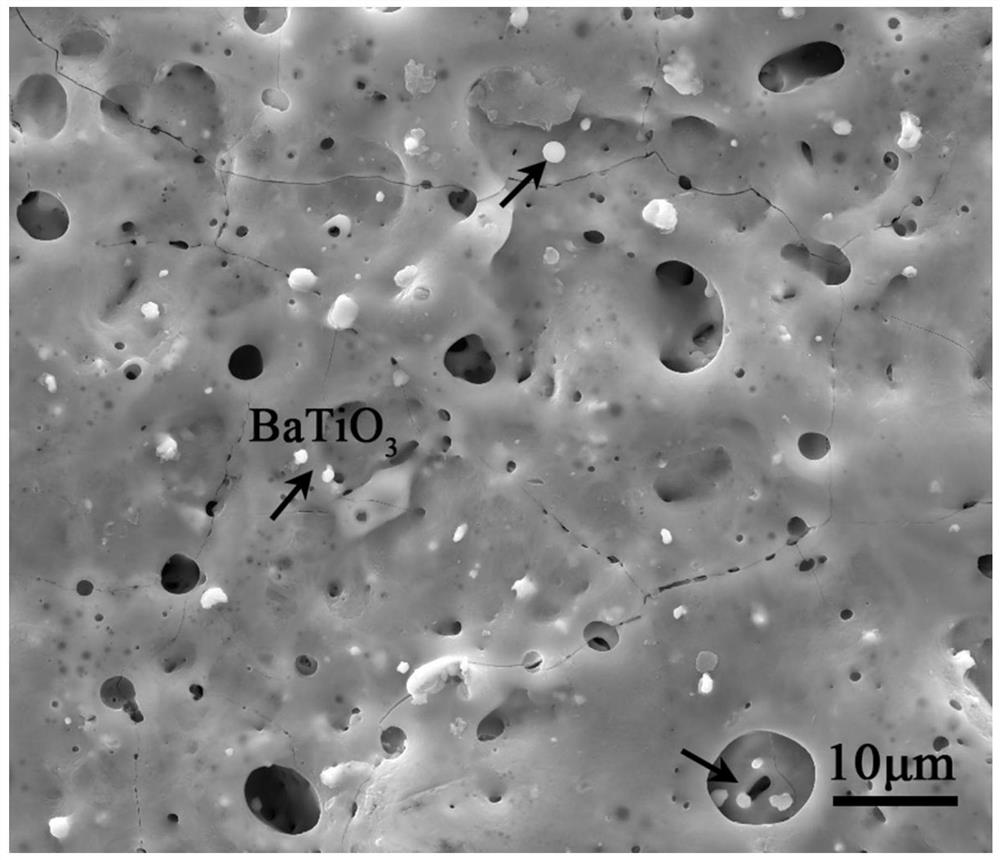

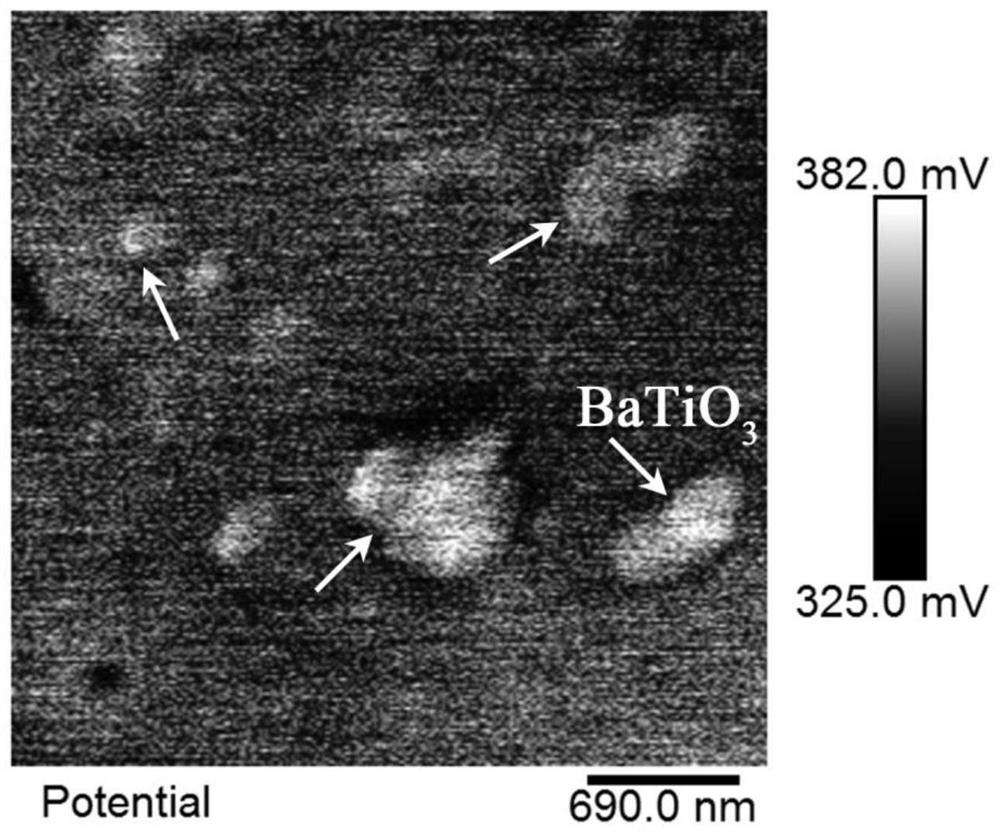

[0055] BaTiO prepared in this example 3 / TiO 2 The surface roughness of the coating is 1.45 μm (the surface roughness of the coating obtained in Example 1 is 2.19 μm). Compared with Example 1, the micro-arc discharge intensity is obviously weakened, the roughness is reduced, the hardness is improved, and the internal defects of ...

Embodiment 3

[0057] This example provides a method for preparing BaTiO on the surface of a titanium substrate 3 / TiO 2 The method of piezoelectric antibacterial coating, the steps are basically the same as in Example 1, the only difference is: in this example, in order to obtain a micro-arc oxidation coating of considerable thickness in step (3), the operation mode is constant current mode. That is, the current is 0.25A, the frequency is 800Hz, and the pulse duty ratio is 30% under the operating parameters of the micro-arc oxidation treatment for 10min.

[0058] BaTiO prepared in this example 3 / TiO 2 The thickness of the coating is 18 μm (the thickness of the coating obtained in Example 1 is 12 μm). Compared with Example 1, although the thickness of the micro-arc oxidation film increases, the oxidation resistance increases, but the oxidation current is constant, so that the micro-arc oxidation resistance is increased. The growth of the oxide film layer did not weaken in the later stage...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com