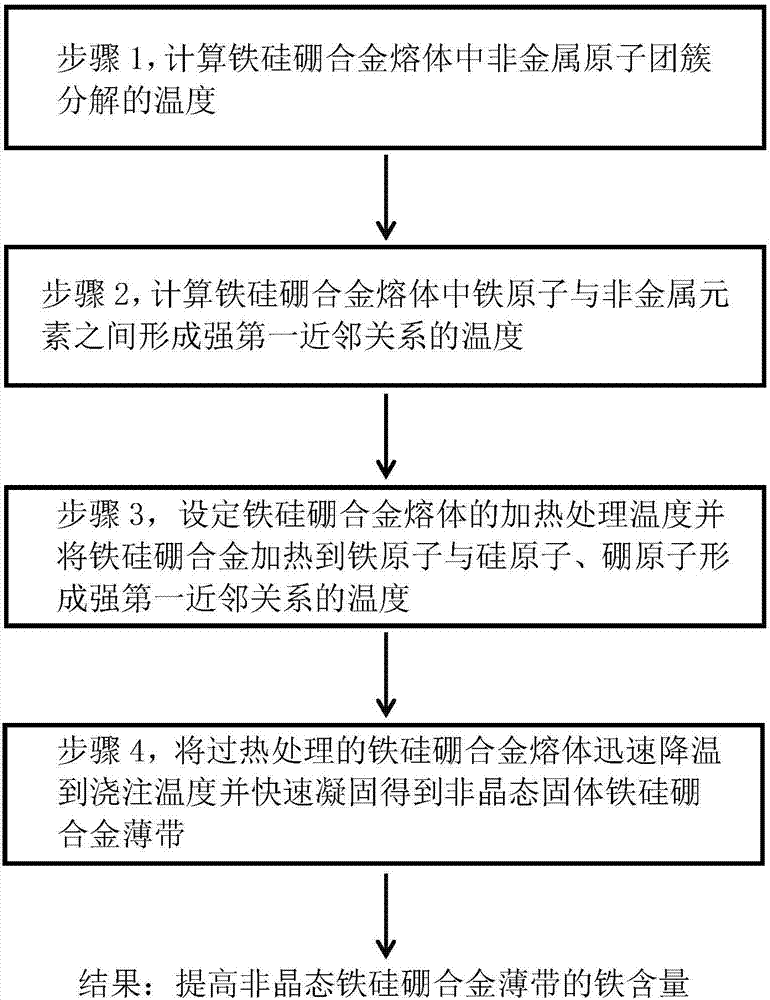

Technological method for increasing content of iron in thin amorphous Fe-Si-B alloy strip

A silicon boron alloy, amorphous iron technology, applied in the field of metal functional material preparation, can solve the problems of enhancing the ability of non-metal elements to form amorphous structures, inability to improve the distribution of non-metal elements, etc., to achieve controllability and High repeatability, high technical reliability, simple implementation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Embodiment 1: adopt amorphous solid alloy Fe 85 Si 9 B 6 Thin strip (the subscript number in the chemical formula is at%), the amorphous solid alloy Fe 85 Si 9 B 6 The thin strips are prepared by the high-speed planar flow continuous casting method commonly used in this field. Next, the specific operation steps of using the processing method of the present invention are as follows:

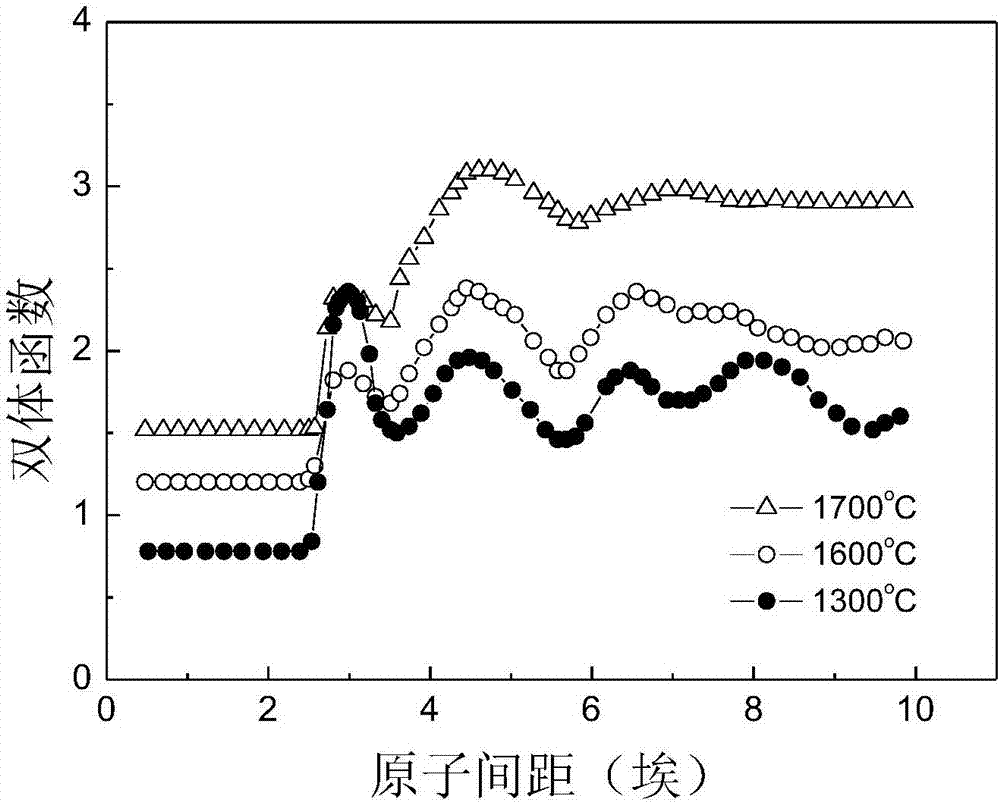

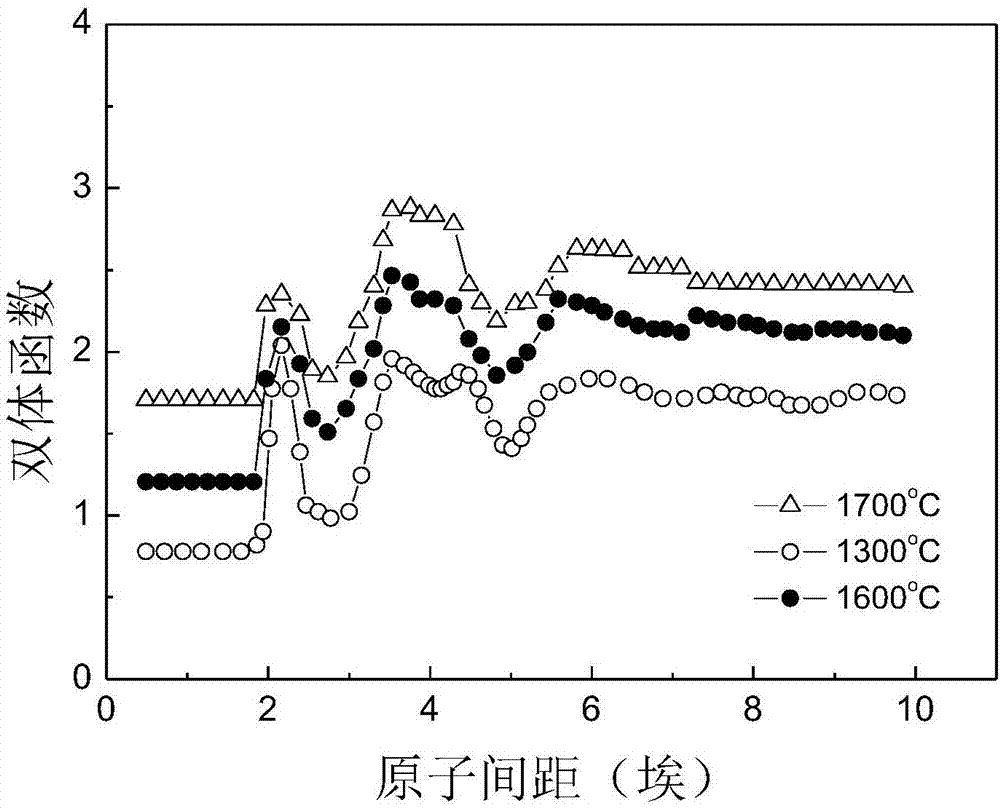

[0037] Step 1, calculate the temperature at which the non-metallic atomic clusters in the iron-silicon-boron alloy melt decompose: there are non-metallic atomic clusters at the initial stage of melting of the iron-silicon-boron alloy, and the non-metallic atomic clusters refer to iron atoms and non-metallic atomic clusters in the iron-silicon-boron alloy melt. Metal atoms form first-neighbor relationships; calculation of Fe using first-principles molecular dynamics simulations85 Si 9 B 6 The two-body function of non-metal atoms in the alloy melt changes with temperature, and the heat...

Embodiment 2

[0047] Embodiment 2: adopt amorphous solid alloy Fe 85 Si 9 B 6 Thin strip (the subscript number in the chemical formula is at%), the amorphous solid alloy Fe 85 Si 9 B 6 The thin strips are prepared by the high-speed planar flow continuous casting method commonly used in this field. Next, the specific operation steps of using the processing method of the present invention are as follows:

[0048] Step 1, calculate the temperature at which the non-metallic atomic clusters in the iron-silicon-boron alloy melt decompose: there are non-metallic atomic clusters at the initial stage of melting of the iron-silicon-boron alloy, and the non-metallic atomic clusters refer to iron atoms and non-metallic atomic clusters in the iron-silicon-boron alloy melt. Metal atoms form first-neighbor relationships; calculation of Fe using first-principles molecular dynamics simulations 85 Si 9 B 6 The two-body function of nonmetal atoms in the alloy melt changes with temperature, and the hea...

Embodiment 3

[0058] Embodiment 3: adopt amorphous solid alloy Fe 85 Si 9 B 6 Thin strip (the subscript number in the chemical formula is at%), the amorphous solid alloy Fe 85Si 9 B 6 The thin strips are prepared by the high-speed planar flow continuous casting method commonly used in this field. Next, the specific operation steps of using the processing method of the present invention are as follows:

[0059] Step 1, calculate the temperature at which the non-metallic atomic clusters in the iron-silicon-boron alloy melt decompose: there are non-metallic atomic clusters in the initial melting of the iron-silicon-boron alloy, and the non-metallic atomic clusters refer to the iron atoms and non-metallic atomic clusters in the iron-silicon-boron alloy melt. Metal atoms form first-neighbor relationships; calculation of Fe using first-principles molecular dynamics simulations 85 Si 9 B 6 The two-body function of non-metal atoms in the alloy melt changes with temperature, and the heating ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com