Method for spraying cracked selenium source on surface of substrate

A substrate surface, selenium source technology, applied in gaseous chemical plating, coating, electrical components, etc., can solve the problems of reducing material utilization, loss of indium and gallium elements, poor reactivity, etc., to improve photoelectric conversion efficiency , Improve the quality of film formation, improve the effect of reactivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

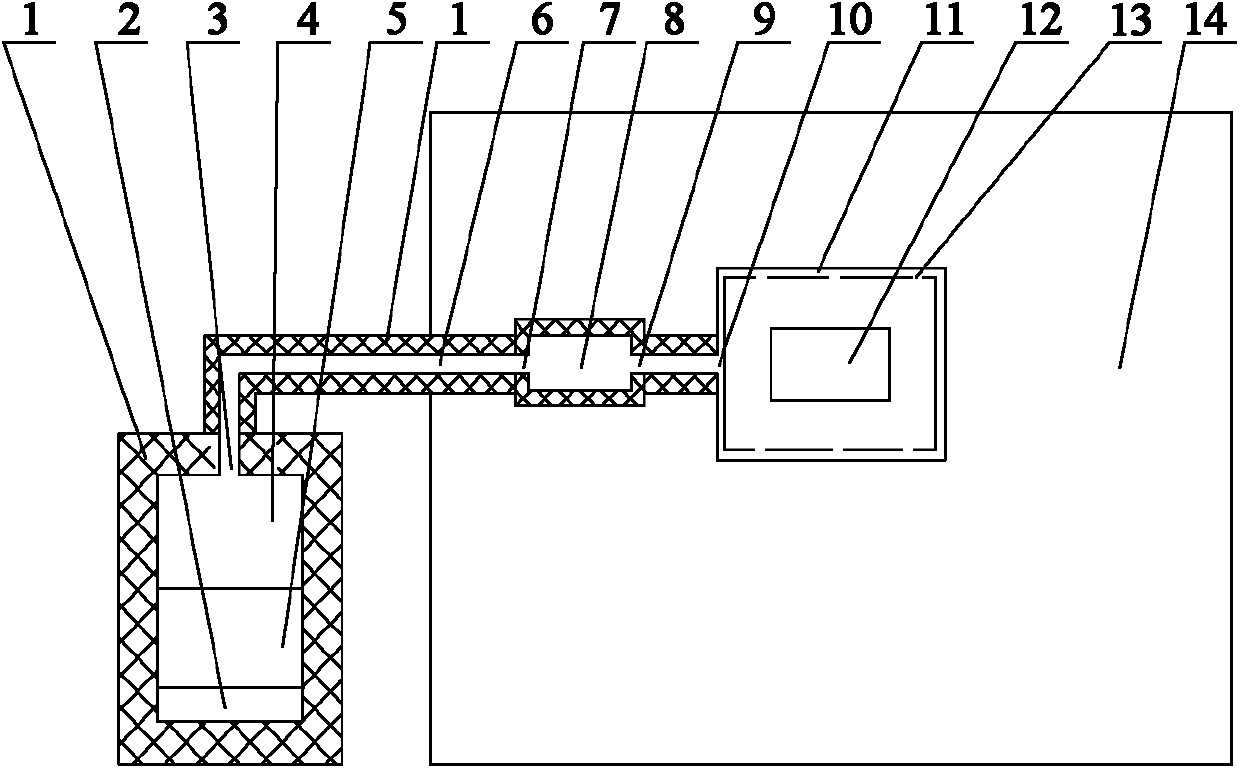

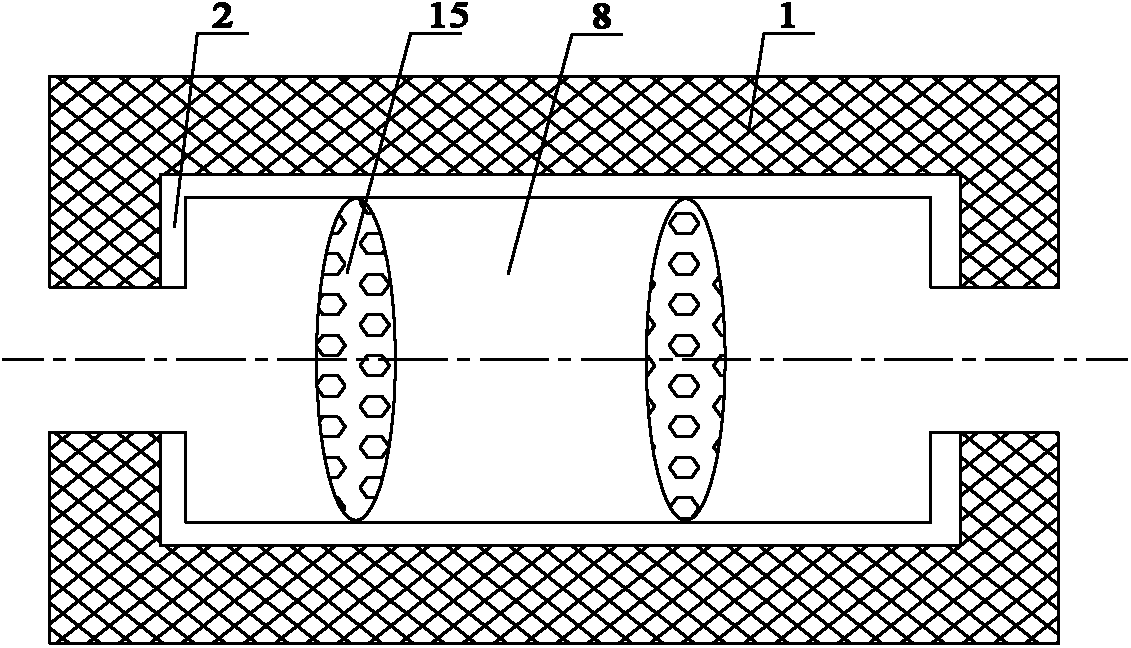

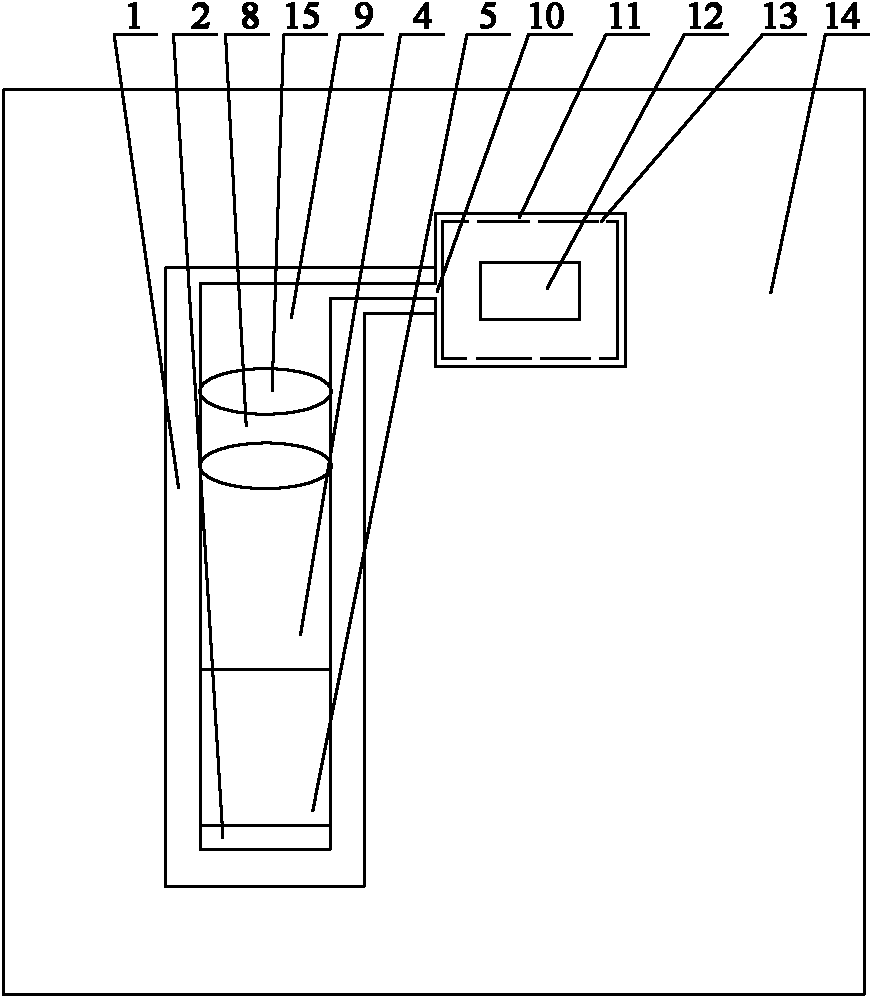

[0024] Refer to attached figure 1 , figure 2 , a method for spraying and cracking a selenium source on the surface of a large-area roll-to-roll flexible substrate, the steps are:

[0025] ⑴ Preparatory work for cracking selenium source:

[0026] Prepare the selenium source evaporation chamber 4, the high temperature cracking chamber 8, the vacuum chamber 14 and the gas outlet pipeline 11 respectively;

[0027] A stainless steel barrel with a volume greater than 1L is selected as the selenium source evaporation chamber, and a small opening on the selenium source evaporation chamber is used as the steam outlet 3. A temperature control heater 2 is arranged at the bottom of the selenium source evaporation chamber, and the solid selenium 5 is located at the temperature control heater. Above; select a stainless steel channel as the high-temperature cracking chamber, one end of the high-temperature cracking chamber is the cracking chamber inlet 7, and the other end is the cracking...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com