Preparation method for thermal barrier coating of high strain tolerance columnar structure

A technology of columnar structure and thermal barrier coating, applied in the field of materials, can solve problems such as the inability to use workpieces with complex structures, and achieve the effect of improving life expectancy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A method for preparing a thermal barrier coating with a high strain tolerance columnar structure, comprising the following steps: placing a superalloy substrate with a bonding layer at a distance of 950mm from the starting point of the mixed beam, and controlling the chamber pressure at 150Pa , the surface of the superalloy was preheated to 960°C, and then the yttrium oxide partially stabilized zirconia (YSZ) powder (M6700, ZrO 2 / Y 2 o 3 =87 / 13, powder particle size -22+5μm) heated and evaporated to form a flow of microparticles containing zirconium ions, oxygen ions, zirconium oxide ions and their clusters, together with plasma gases Ar gas and He gas to form a mixed beam. The intake volumes of the plasma gases Ar and He are 35NLPM and 60NLPM, respectively. The beam is continuously deposited on the superalloy substrate, and the deposition time is 20 minutes.

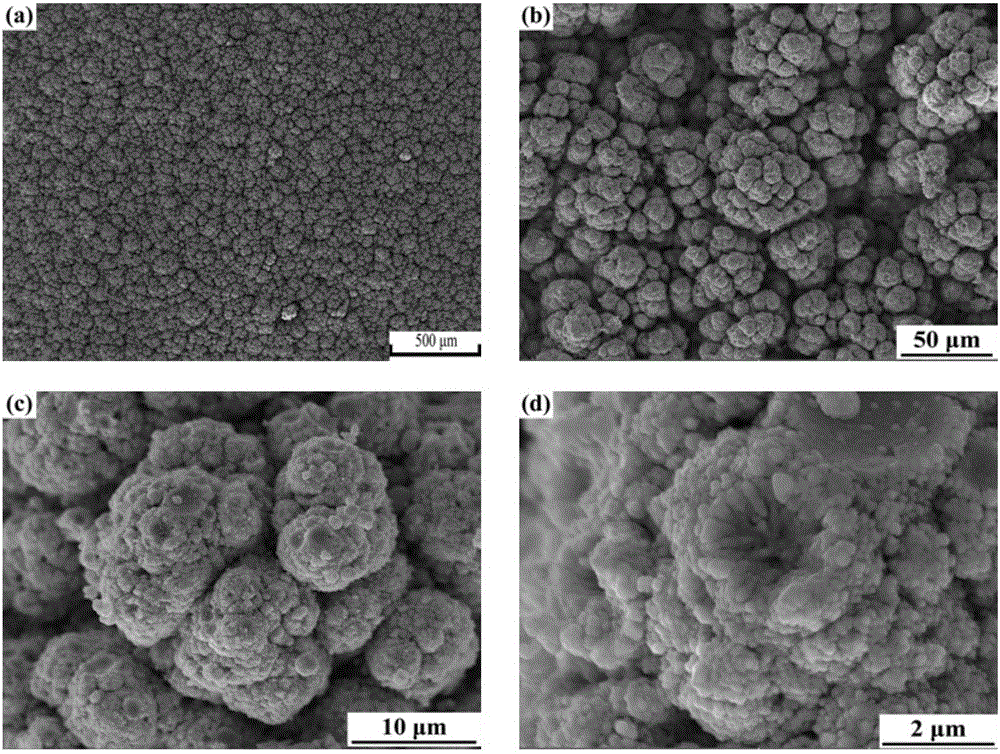

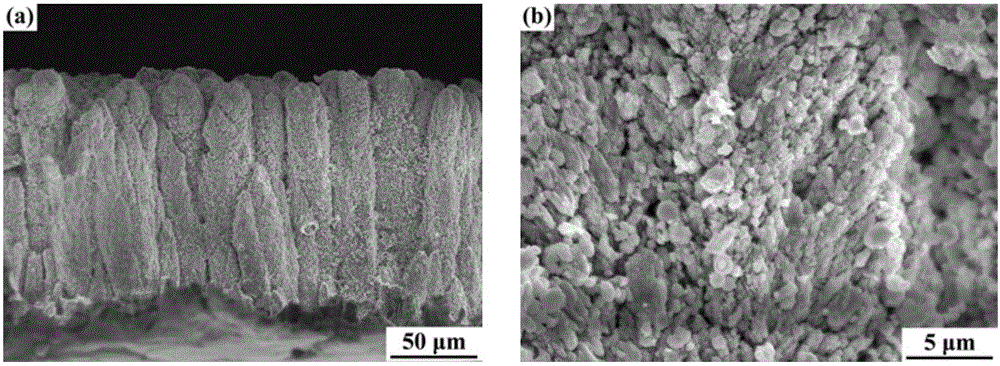

[0030] The surface structure of the thermal barrier coating prepared in Example 1 is as follows: figure 1...

Embodiment 2

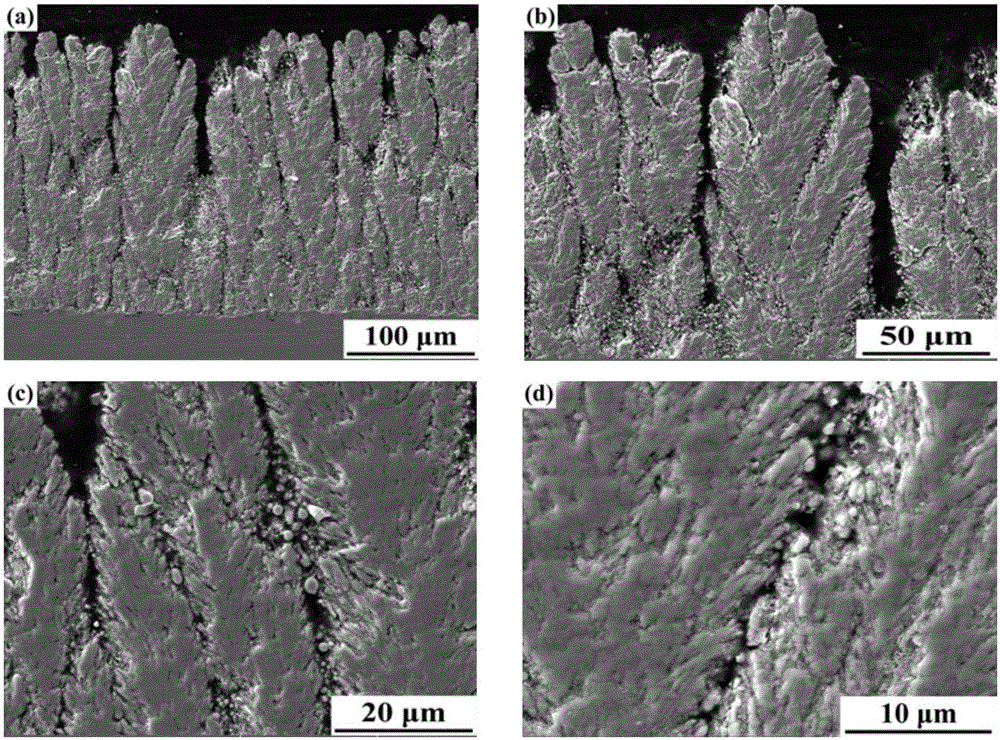

[0032] A method for preparing a thermal barrier coating with a high strain tolerance columnar structure, comprising the following steps: placing a superalloy substrate with a bonding layer at a distance of 350mm from the starting point of the mixed beam, and controlling the chamber pressure at 10Pa , the superalloy surface is preheated to 850 °C, and then the lanthanum zirconate La 2 Zr 2 o 7 (LZO) powder is heated and evaporated to form a flow of fine particles containing lanthanum ions, zirconium ions, oxygen ions, zirconium oxide ions and their clusters, which together with the carrier gas Ar gas form a mixed beam flow. Finally, the superalloy substrate is deposited intermittently by scanning at a scanning speed of 1000mm / s.

Embodiment 3

[0034]A method for preparing a thermal barrier coating with a high strain tolerance columnar structure, comprising the following steps: placing a stainless steel substrate with an adhesive layer at a distance of 900mm from the starting point of the mixed beam, controlling the chamber pressure at 350Pa, The stainless steel surface is preheated to 720°C, and then the cerium oxide CeO 2 The powder is heated and evaporated to form a flow of fine particles containing cerium ions, oxygen ions, cerium oxide ions and their clusters, which together with plasma gases Ar and He form a mixed beam. The intake volumes of the plasma gases Ar and He are 30NLPM and 55NLPM, respectively. Finally, scanning intermittent deposition is carried out on the stainless steel substrate at a scanning speed of 500mm / s.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com