Preparation method of nanometer silicon composite material with core-shell structure

A composite material, shell-core structure technology, applied in the field of nanomaterials, can solve the problems of nano-silicon material agglomeration and oxidation, difficulty of silicon nanopowder, influence of product purity, etc., to prevent agglomeration and oxidation, high material utilization rate, good choice Effects of Sexual Doping Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

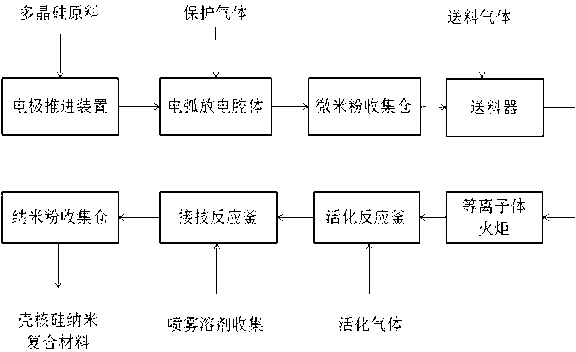

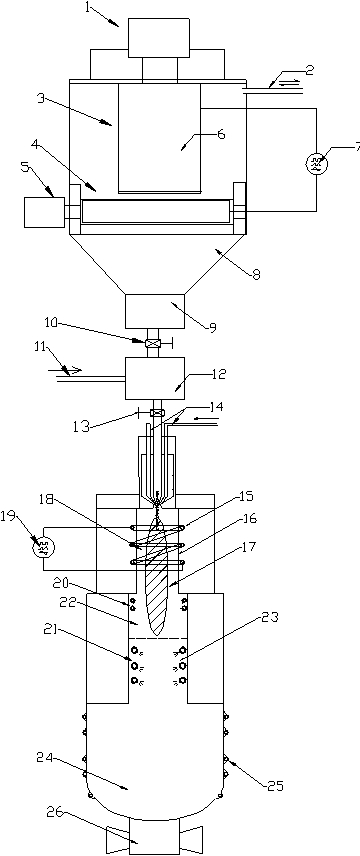

[0063] Such as figure 1 and figure 2 Shown: A protective atmosphere is introduced into the DC arc discharge generator, and the silicon rod is loaded into the anode of the arc generator and becomes a part of the anode. The second electrode 4 rotates under the drive of the connected rotary motor 5 at a speed of 30 rpm. It can be observed that a continuous spark discharge occurs between the first electrode 3 and the second electrode 4 . When discharging, the voltage drops from the set value of 300V to 20V, and the current rises from the set value of 16.7A to 250A. After each spark discharge, the stepper motor 1 moves the first electrode 3 to make it short-circuit with the second electrode 4, and then moves the first electrode 3 back to the set electrode spacing of 1 mm for the next spark. discharge. After 4 hours of continuous operation, about 4 kg of silicon powder was collected. The micron-sized silicon particles were spherical, with an average diameter of 50 microns and a...

Embodiment 2

[0066] Such as figure 1 and figure 2 As shown, a protective atmosphere is introduced into the DC arc discharge generator, and the silicon rod is loaded into the anode of the arc generator and becomes a part of the anode. The second electrode 4 is driven to rotate by the connected rotating motor 5 at a speed of 20 revolutions per minute. It can be observed that a continuous spark discharge occurs between the first electrode 3 and the second electrode 4 . When discharging, the voltage drops from the set value of 350V to 10V, and the current rises from the set value of 15A to 250A. After each spark discharge, the stepper motor 1 moves the first electrode 3 to make it short-circuit with the second electrode 4, and then moves the first electrode 3 back to the set electrode spacing of 0.8mm, and proceeds to the next step. spark discharge. After 2 hours of continuous operation, about 3 kg of silicon powder was collected, and the micron-sized silicon particles were spherical with...

Embodiment 3

[0069] A protective atmosphere is introduced into the DC arc discharge generator, and the silicon rod is loaded into the anode of the arc generator and becomes a part of the anode. The second electrode 4 rotates under the drive of the connected rotary motor 5 at a speed of 30 rpm. It can be observed that a continuous spark discharge occurs between the first electrode 3 and the second electrode 4 . When discharging, the voltage drops from the set value of 300V to 20V, and the current rises from the set value of 16.7A to 250A. After each spark discharge, the stepper motor 1 moves the first electrode 3 to make it short-circuit with the second electrode 4, and then moves the first electrode 3 back to the set electrode spacing of 1 mm for the next spark. discharge. After 4 hours of continuous operation, about 4 kg of silicon powder was collected. The micron-sized silicon particles were spherical, with an average diameter of 50 microns and a purity higher than 6N.

[0070]Open th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average diameter | aaaaa | aaaaa |

| The average diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com