Recycling treatment method and apparatus for oil-containing sludge

A resource-based, oil-water separation device technology, which is applied in the field of oily sludge treatment, can solve the problems of relatively harsh treatment scale process conditions, the influence and limitation of mixed bacterial agent biological treatment, and insufficient energy utilization of pyrolysis oil and gas, etc., to achieve the realization of Acceleration and strengthening effect, improving the effect of plasma gasification, reducing the effect of electric power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

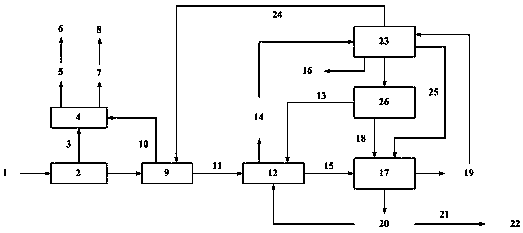

Image

Examples

Embodiment 1

[0045] (1) The oily sludge with a moisture content of 96wt% or more is dehydrated by the screw stacker and the air flotation device, and the small particle oily sludge is flocculated and precipitated by adding polyacrylamide flocculant, and dehydrated by the screw stacker The treatment reduces the water content to 80wt%~90wt%. The sewage generated during the dehydration process of the screw stacker is sent to the air flotation machine for secondary dehydration treatment. The generated scum is returned to the screw stacker, and the generated sewage is sent to the oil-water separation device;

[0046] (2) The dehydrated oily sludge with a moisture content of 80wt%~90wt% is transported to the multi-layer film evaporation and drying device through the sludge screw pump for drying treatment, and the dehydrated oily sludge is dried with saturated steam at 160~180°C Drying and purging, the drying temperature of the inner layer of the film can reach 120-140°C, and the purging temperat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com