Plasma gasification treatment system of solid organic waste

A technology of organic waste and solid waste, applied in the field of ion gasification treatment system, can solve the problems of use restriction, different use process, different ash melting point, etc., achieve the effect of efficient conversion, reduce emission and eliminate pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

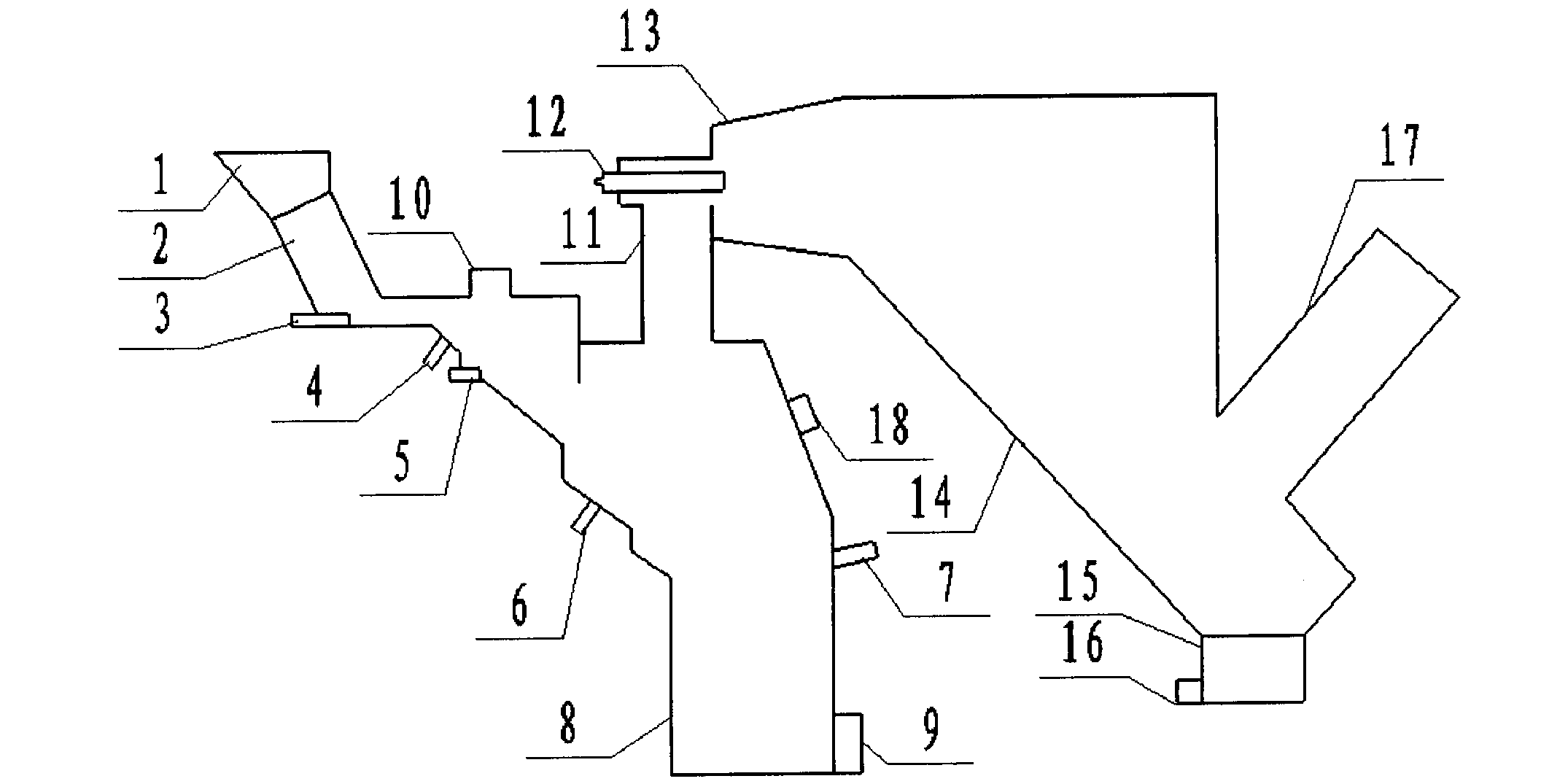

[0024] Such as figure 1 As shown, the solid organic waste plasma gasification treatment system of the present invention includes a feeding part, a drying device, a gasification furnace, and a synthesis gas purification device connected in sequence.

[0025] The feeding part includes a feeding device 1, a feeding channel 2, and a first push plate 3; the first pushing plate is installed on the feeding channel 2; the solid organic waste falling from the feeding channel 2 is passed through the first pushing plate 3 Push the material into the drying device. The feeding channel 2 is an inclined pipeline with an angle of about 45°-60°.

[0026] The drying device includes a drying hot air pipe 4 , a second push plate 5 , and a wet steam outlet 10 . A wet steam outlet 10 is formed on the top of the drying device, and a dry hot air pipe 4 and a second push plate 5 are installed on the side wall of the drying device. Heat is provided to the drying device through the dry hot gas pipe 4...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com