Plasma gasification equipment for changing garbage raw material to be syngas of high heat value

A technology of plasma and gasification equipment, applied in the field of garbage treatment equipment, can solve the problems of low calorific value, low calorific value of synthesis gas, small economic output/input ratio, etc., and achieves simple equipment structure, high energy conversion rate, The effect of relieving energy stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

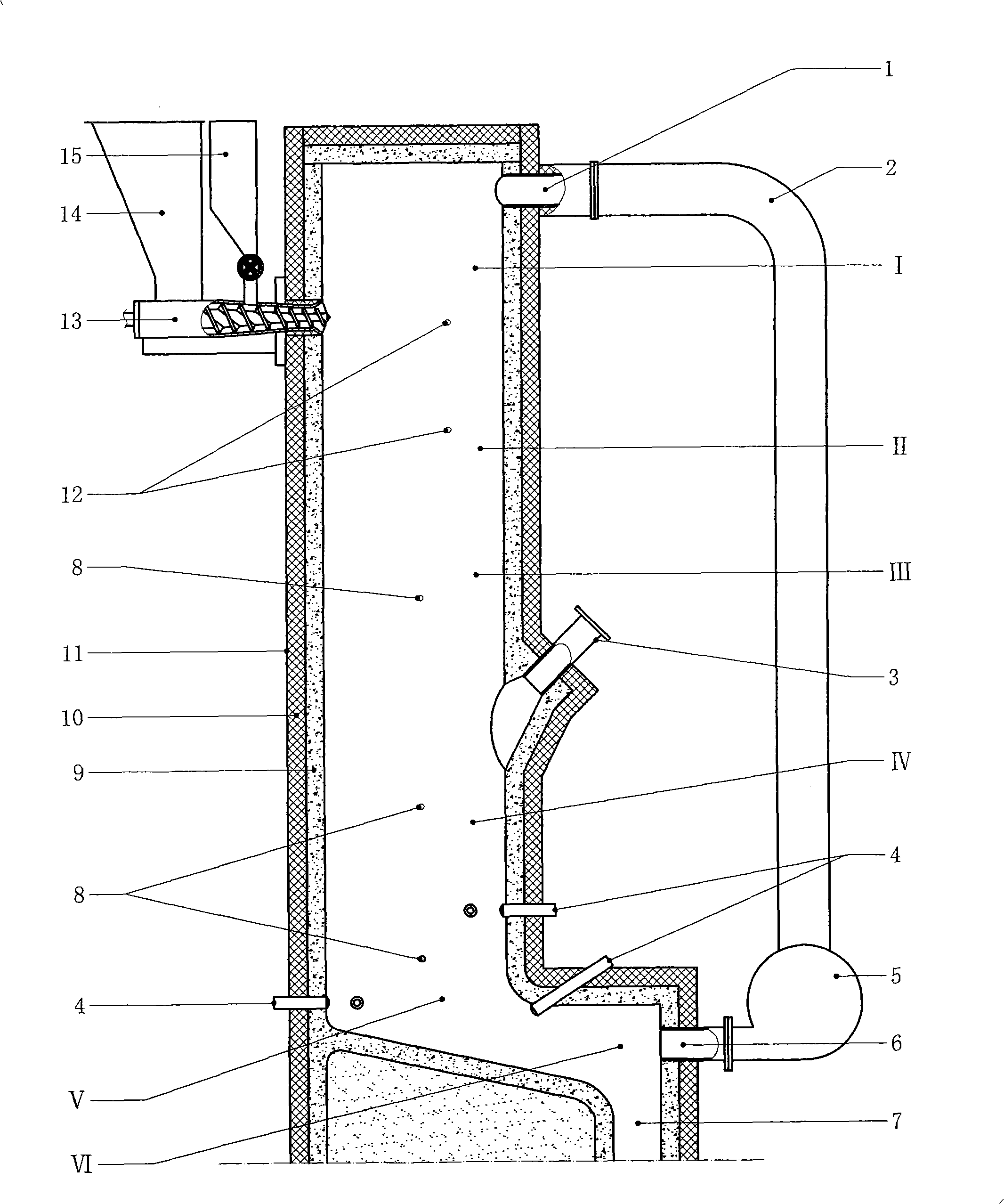

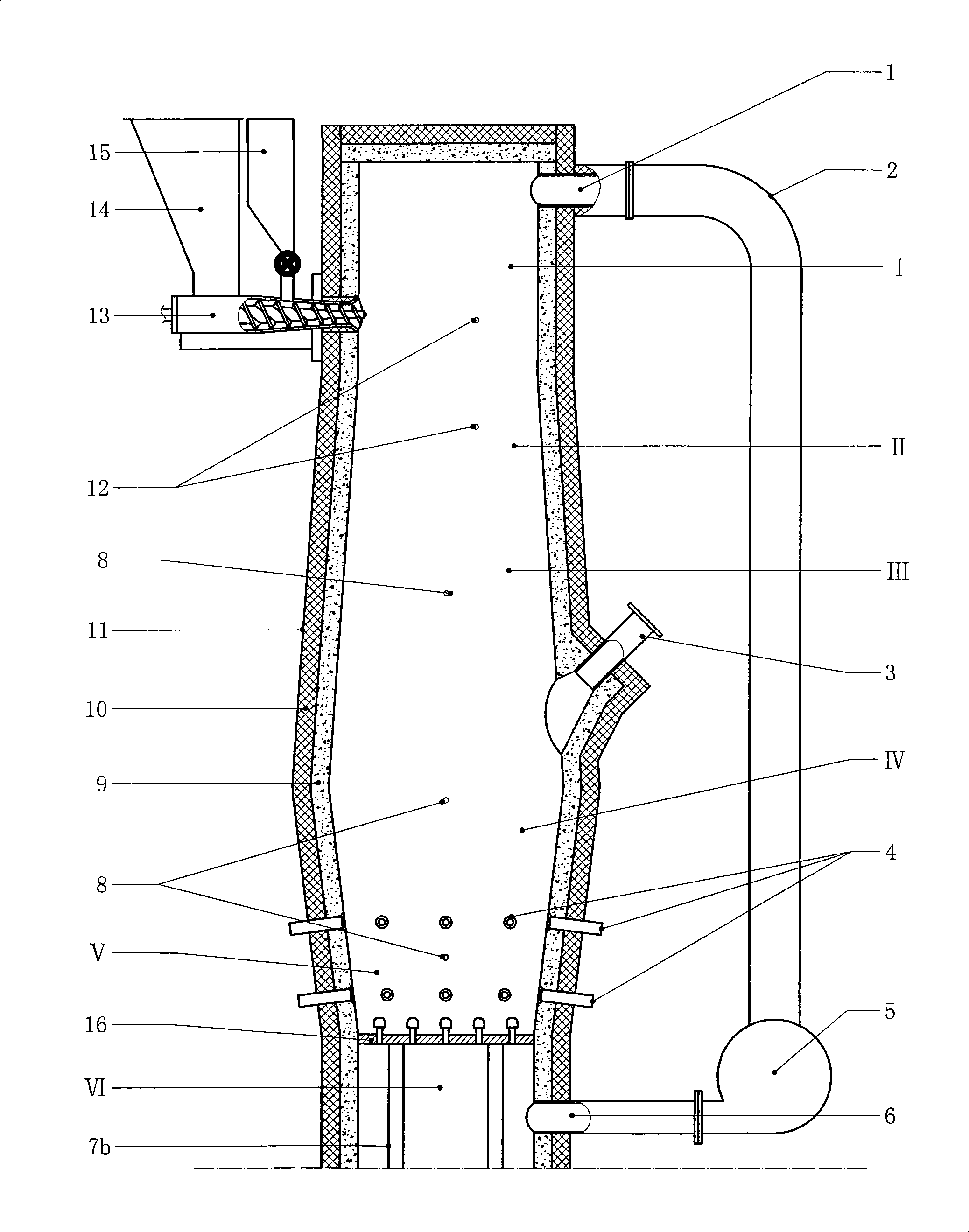

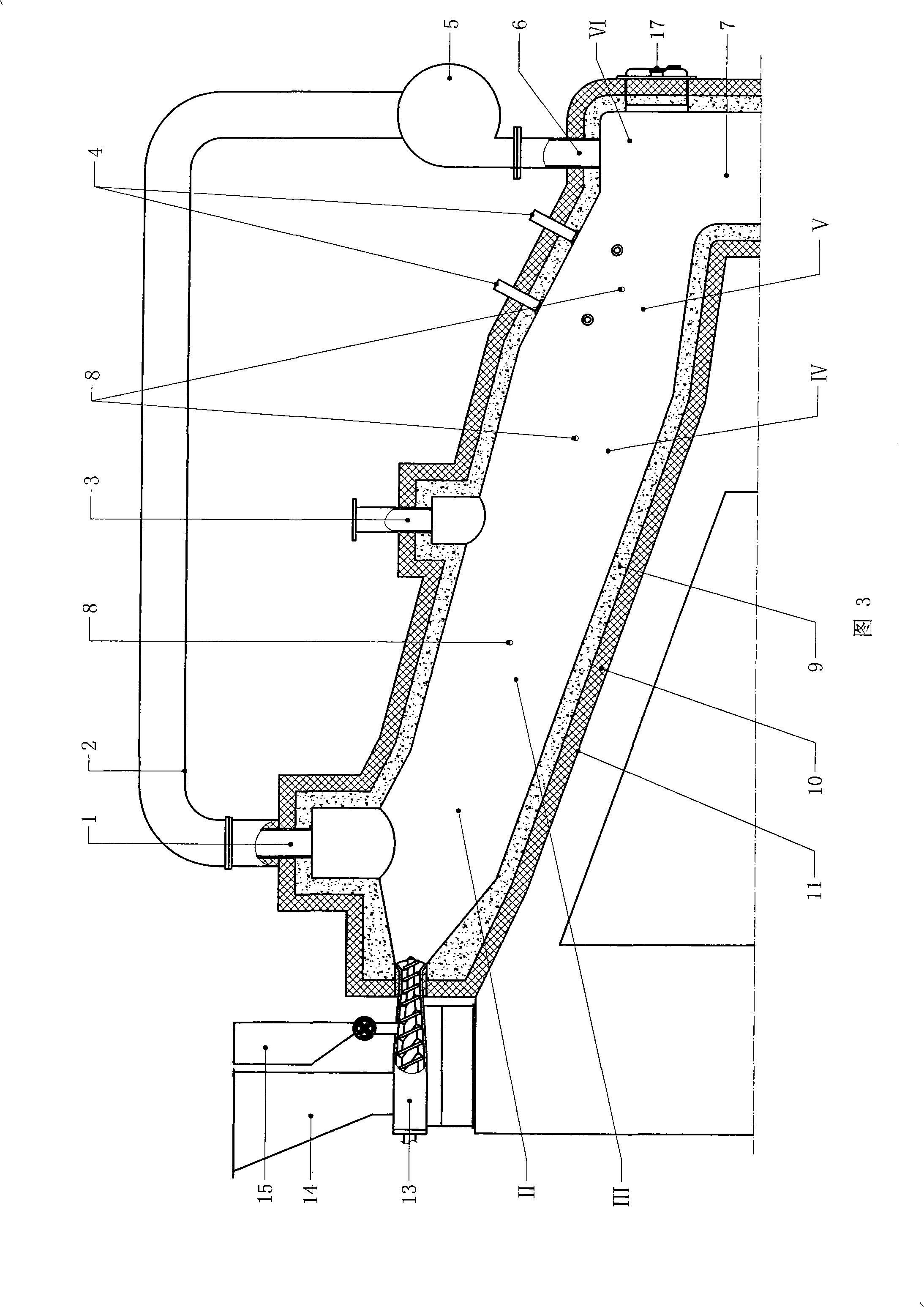

[0017] figure 1 In the shown embodiment, the gasification equipment is mainly composed of a gasification reaction furnace, a flue gas circulation air duct (2), a circulation fan (5), a plasma spray gun (4), an extrusion screw feeder (13), Garbage hopper (14) and additive hopper (15) are made up of, and wherein: gasification reaction furnace is formed blast furnace type furnace body by cylinder refractory furnace wall (9), insulation layer (10), shell (11), and refractory furnace wall ( 9) In the innermost layer, the outer layer of the refractory furnace wall (9) is the insulation layer (10), and the outer layer of the insulation layer (10) is the shell (11); Zone (I), Drying Zone (II), Pyrolysis Zone (III), Gasification Zone (IV), Burnout Zone (V) and Air Chamber (VI), Smoke Gathering Zone (I), Drying Zone ( II), the pyrolysis zone (III), the gasification zone (IV) and the burnout zone (V) are successively connected up and down, the smoke gathering zone (I) is in the upper pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com