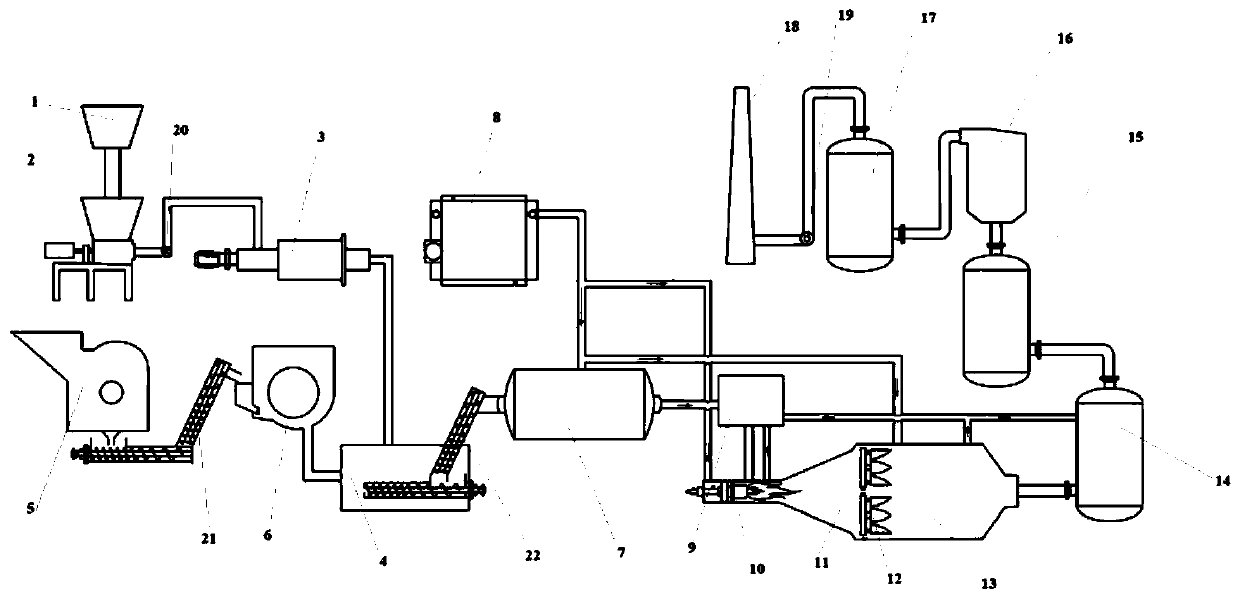

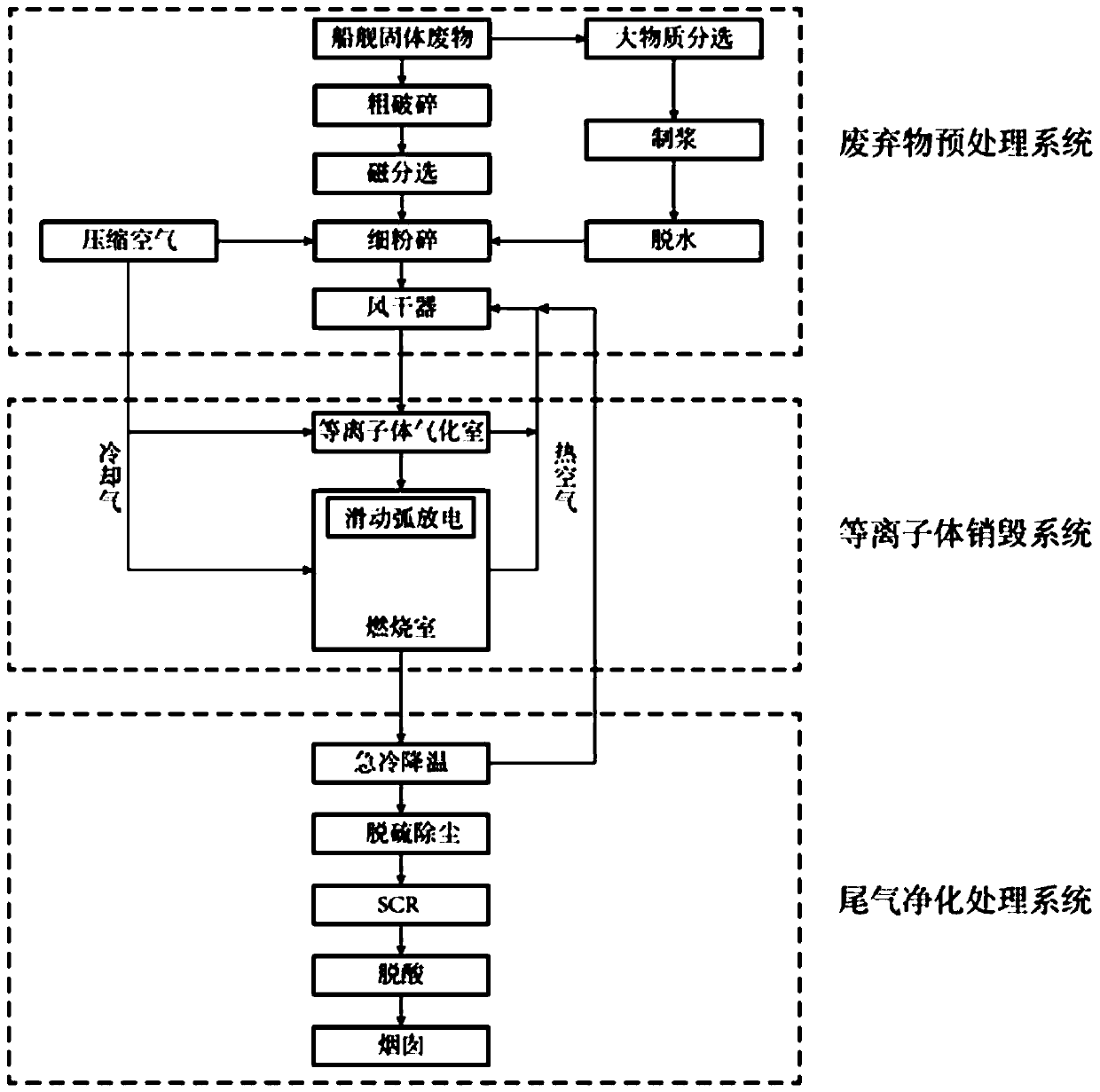

Multi-stage plasma processing method and multi-stage plasma processing system for solid waste of ship

A plasma and solid waste technology, applied in the field of plasma treatment methods and systems, can solve the problems of insufficient specific surface area of pretreated solid waste, unstable combustion chamber flame, and enhanced utilization of waste heat, etc., to achieve volume reduction and moisture content of materials The effect of reducing and stabilizing the flame

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0063] A method for multi-stage plasma treatment of ship solid waste, which can be used to treat kitchen waste, with a feed rate of 300kg / h. The specific feed depends on the classification of kitchen waste, including the following steps:

[0064] (1) The food waste with high water content is sorted into the pulping machine after being sorted by large materials, and is pumped into the dehydrator for dehydration through a centrifugal pump. The materials with a water content of less than 50% and a weight of less than 5% leave the storage room The dehydrator described above has an entry volume of 2.5m 3 Transit mixing warehouse.

[0065] (2) Food waste with low moisture content enters the crusher to reduce the size of the material to less than 2.5cm, and then use a suitable screw conveyor to transport the crushed material to the magnetic separator to separate the metal in the material After that, enter the transit mixing bin.

[0066] (3) After the materials in the transfer mixi...

Embodiment 2

[0071] A method for multi-stage plasma treatment of ship solid waste for mixed organic-rich solid waste (eg, 50% food waste + 15% paper + 20% cardboard + 5% rags + 10% plastic) , the feed rate is 300kg / h, the specific feed rate depends on the garbage classification, including the following steps:

[0072] (1) The food waste with high moisture content is sorted into the pulping machine after being sorted by large materials, and then pumped into the dehydrator by a centrifugal pump for dehydration. The materials with a moisture content of less than 50% and a weight of less than 5% leave The dehydrator has an entry volume of 2.5m 3 Transit mixing warehouse;

[0073] (2) Dry food waste, paper, cardboard, rags and plastics enter the crusher to crush the material to a size below 2.5cm, and then use a suitable screw conveyor to transport the crushed material to a magnetic separator for After the metal in the material is separated, it enters the transfer mixing bin;

[0074] (3) Af...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com