Power generation method and device adopting plasma gasification of household garbage and biomass

A biomass power generation and plasma technology, used in gas turbine devices, internal combustion piston engines, combustion engines, etc., can solve the problems of uneven temperature field and flow field, limited plasma torch power, and no use of garbage calorific value, etc. Small footprint, high volume reduction ratio and good economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

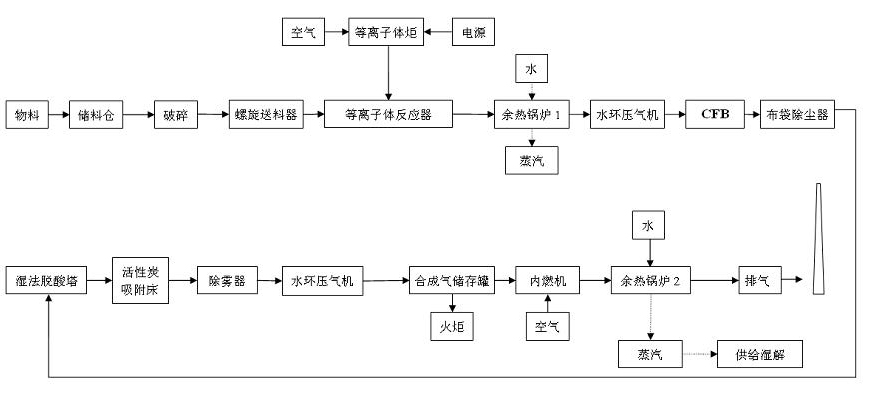

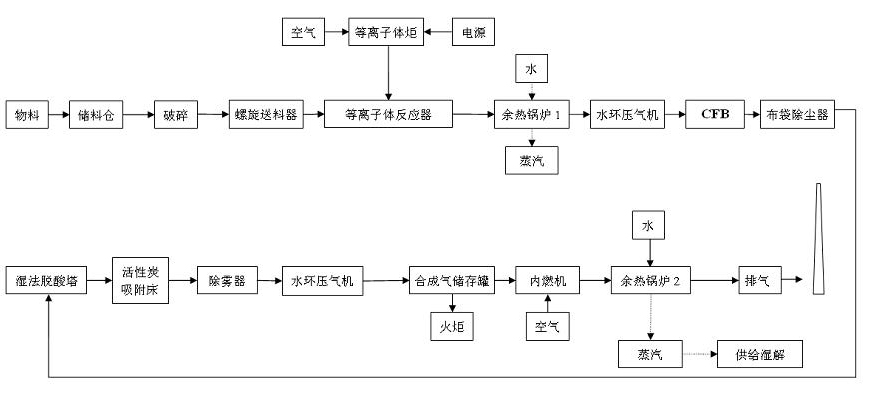

[0033] Such as figure 1 As shown, the method of plasma gasification of domestic waste and biomass power generation of the present invention, the method steps of this embodiment are carried out in the following order:

[0034] 1) Firstly, the sorted and collected garbage to be processed is crushed. After the material is crushed, the particle size is less than 50mm, so that its size is suitable for the form of plasma reactor processing. Then dry it to reduce its moisture content to between 10% and 40%, and the best moisture content is 20% to 30% to increase its calorific value. Then the garbage is continuously sent to the plasma reactor of the present invention through the screw feeding system. The energy used for drying comes from the recovered syngas and the heat energy of the exhaust gas of the internal combustion engine generator. The dried gas is condensed to separate water, and the remaining gas is pumped into the plasma reactor or the gas engine;

[0035] 2) Gasificatio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com