Gasification-liquefaction disposal method, system and equipment for household garbage

A domestic garbage and gasifier technology, which is applied in waste treatment, combustible gas production, solid waste removal, etc., can solve problems such as dioxin pollution that destroys the human living environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

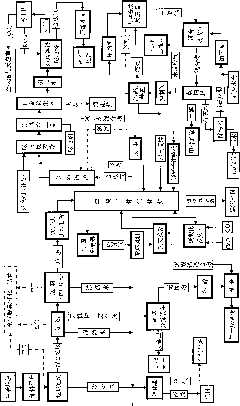

[0028] Example 1 figure 1 In the embodiment shown, domestic garbage or organic waste is fermented to remove part of the water in the garbage storage pit, and then through sorting, the sorted organic waste materials are sent to the screw feeder, and the conveying of the screw feeder During the process, part of the water is removed again by extrusion, and the waste material is passed through CO 2 The gas-sealed feeding device is sent into the plasma gasification furnace; the garbage material is dried and pyrolyzed through the drying section and the pyrolysis section in the plasma gasification furnace, and then becomes garbage charcoal and enters the gasification section, and is separated from the The water vapor decomposition products sprayed into the gasification section by the plasma spray gun undergo gasification reaction, complete gasification, and generate CO and H 2 Hydrogen-rich syngas as the main component; the operating temperature of the drying section is controlled b...

Embodiment 2

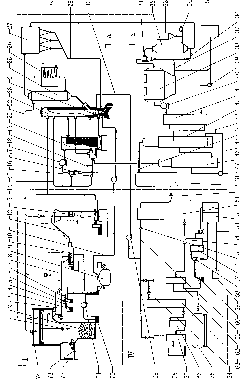

[0029] Embodiment 2 This embodiment is for example figure 2 The general diagram of the system and Figure 4 , 5 As shown in the detailed drawings of , 6 and 7, the domestic waste gasification-liquefaction disposal system includes: the domestic waste pretreatment part ( figure 2 I zone), plasma gasification part ( figure 2 II-a zone), syngas purification part ( figure 2 III-a region) and methanol synthesis and end purification part ( figure 2 IV zone), the system mainly consists of unloading platform (73), garbage storage pit (2), crane grab (1), sorting machine (3), screw squeeze water / feeder (10), CO 2 Gas seal feeding device (13), plasma gasifier (23), plasma spray gun (24), gas-solid separator (17), circulation fan (18), carbonation reaction chamber (2007), heat exchanger (20), waste heat boiler (27), absorption reactor (32), cyclone dust collector (31), bag filter (38), induced draft fan (40), carbon monoxide shift reactor (41), CO 2Absorption tower (42), regene...

Embodiment 3

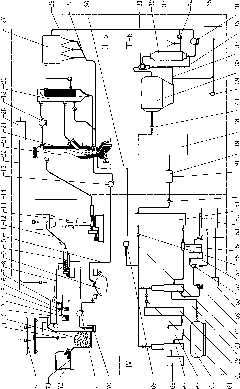

[0030] Embodiment 3 This embodiment is for example image 3 The general diagram of the system and Figure 4 , 7 As shown in the detailed drawings of , 8 and 9, the domestic waste gasification-liquefaction disposal system includes: the domestic waste pretreatment part ( image 3 I zone), plasma gasification part ( image 3 II-b zone), syngas purification part ( image 3 III-b region) and methanol synthesis and end purification part ( image 3 IV area), the system mainly consists of unloading platform (73), crane grab (1), garbage storage pit (2), sorting machine (3), digester (9), screw squeeze water / feeder ( 10), CO 2Gas seal feeding device (13), plasma gasifier (23), plasma spray gun (24), circulation fan (18), heat exchanger b (21), waste heat boiler (27), induced draft fan (40) , absorption reactor (32), cyclone dust collector (31), bag filter (38), compressor a (44), synthesis gas storage tank (48), hydrogenation mixer (49), compressor (51 ), methanol synthesis reac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com