Garbage plasma gasification furnace taking vapor as gasification medium

A technology of gasification medium and plasma, which is applied in the direction of gasification process, manufacture of combustible gas, petroleum industry, etc., can solve the problems of low gas yield, instability, waste residue treatment and other problems, and achieve uniform flow field and temperature field, The effect of prolonging the service life and reducing operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

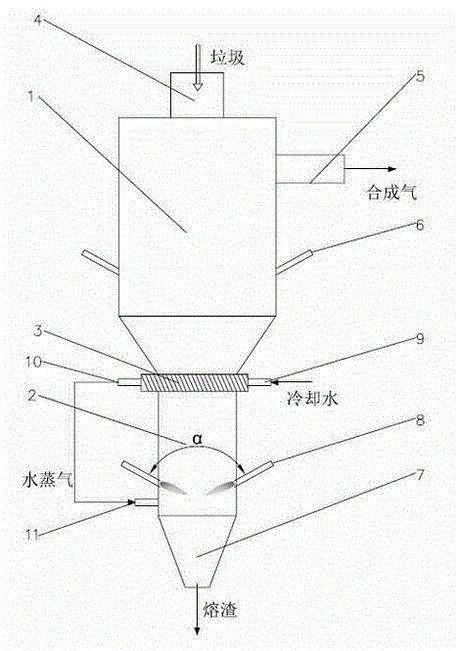

[0024] The present invention provides a garbage plasma gasification furnace using water vapor as the gasification medium, which is composed of an upper garbage gasification chamber 1 and a lower high-temperature steam generation chamber 2, and the upper and lower parts are composed of water-cooled furnace arches arranged at intervals 3 Separated, the inner wall of the gasifier is poured with refractory materials.

[0025] The top of the waste gasification chamber 1 is equipped with a feeding port 4, the side is provided with a syngas outlet 5 at a higher position, and the side is provided with an air supply port 6 at a lower position; the bottom of the high-temperature steam generating chamber 2 is a slag discharge port 7, and the sides are arranged circumferentially Two plasma torches 8, the angle between the two plasma torches 8 is α, and α is 120°-150°; low-temperature water vapor with a temperature of 150°C-250°C is used as the working gas of the plasma torch 8, and at the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com