Coal gasification process for methane preparation by two stage gasification stove

A technology of gasification furnace and coal gasification, which is applied in the direction of gasification process, hydrocarbon production from carbon oxides, granular/powdered fuel gasification, etc. It can solve the problems of increasing system energy consumption, equipment size, and large circulation volume.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

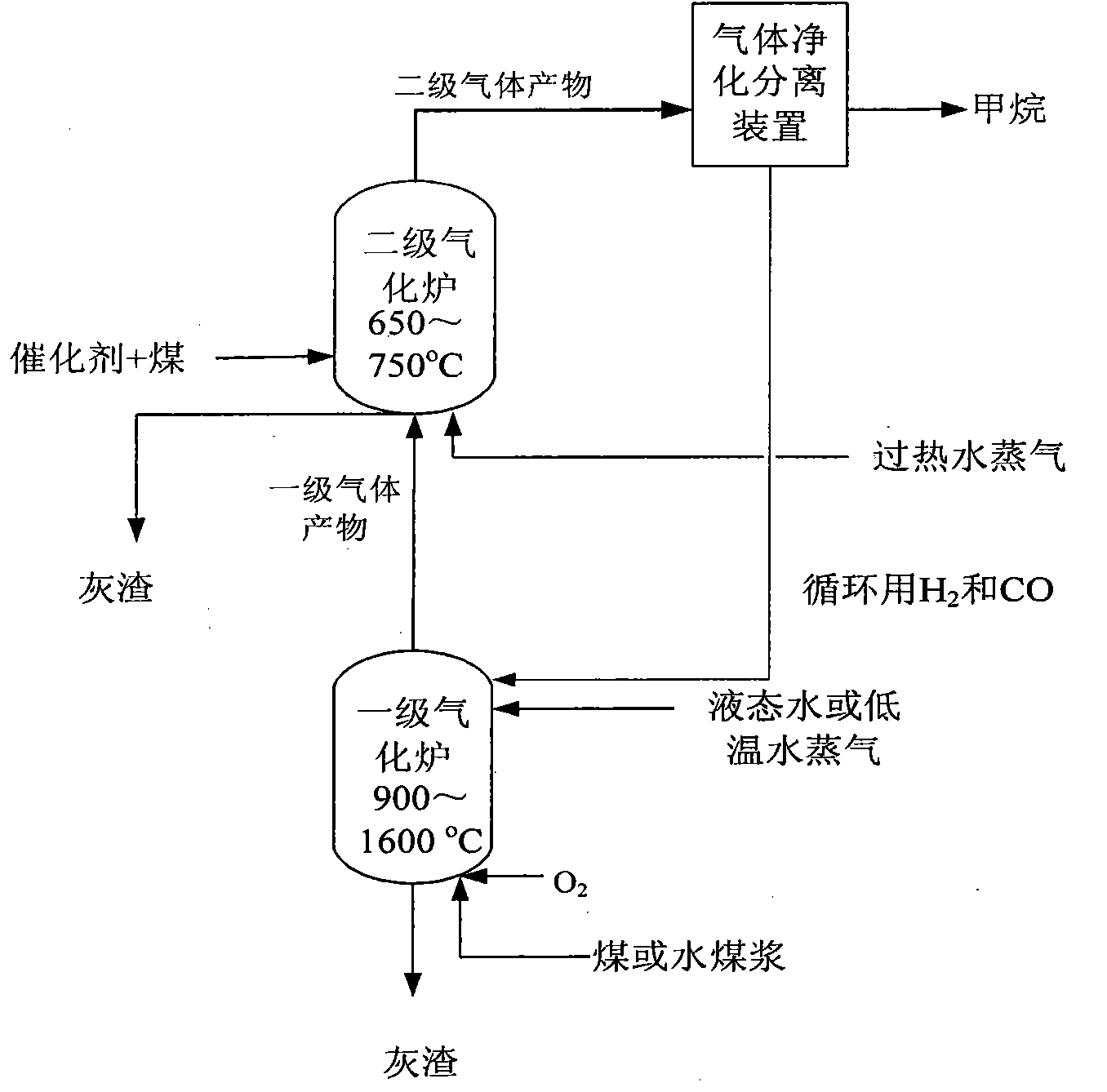

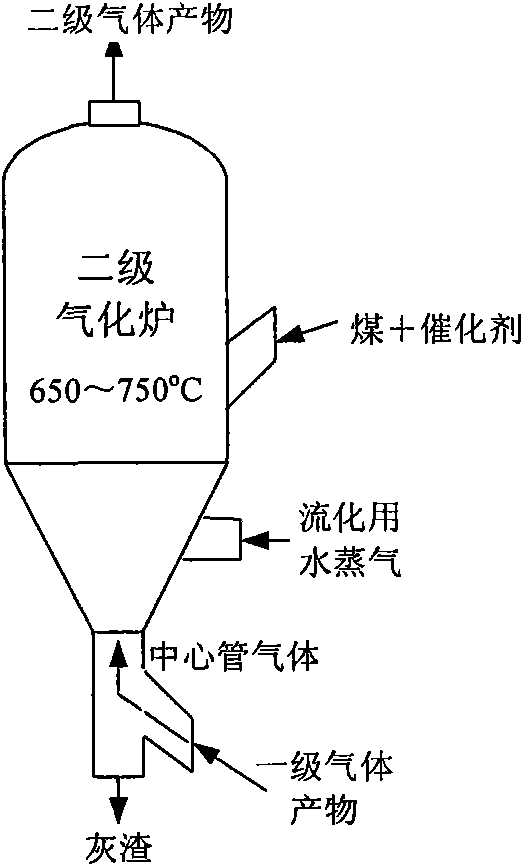

[0019] The process of the invention is carried out in two-stage gasifiers connected in series. Combine below figure 1 The present invention is explained in detail.

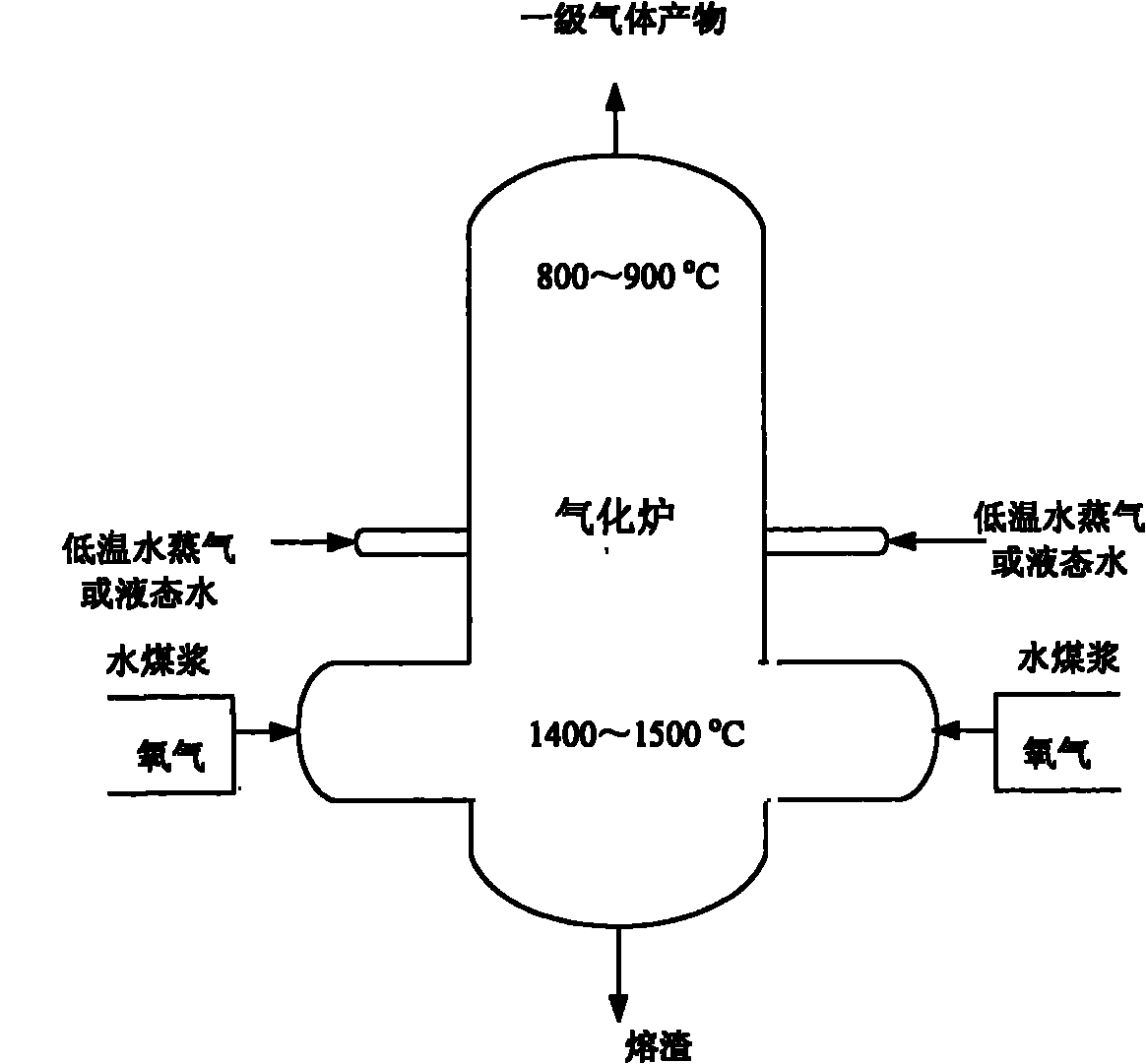

[0020] In step a of the present invention, coal and oxygen-containing gas are reacted in a primary gasifier to generate gas containing CO, CO 2 、H 2 、H 2 O gasification gas products. Wherein the coal can be passed into the primary gasifier in the form of coal-water slurry or dry coal powder, and the feed equipment is conventional slurry feed equipment in the field such as high-pressure coal-water slurry delivery pump (such as diaphragm pump) and coal-water Slurry nozzles or solid feeding equipment such as lock hopper feeding and pressurized blowing equipment. At the same time, oxygen-containing gas is fed into the primary gasifier, and the oxygen-containing gas can be air, oxygen-enriched air or pure oxygen. Coal and oxygen undergo a gasification reaction at a temperature of 900-1600°C and a pressure of 20-7...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com