Plasma waste gasification and pyrolysis equipment

A technology of plasma and plasma torch, which is applied in the field of ion waste gasification pyrolysis equipment, can solve the problem of low energy utilization rate and achieve high energy utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

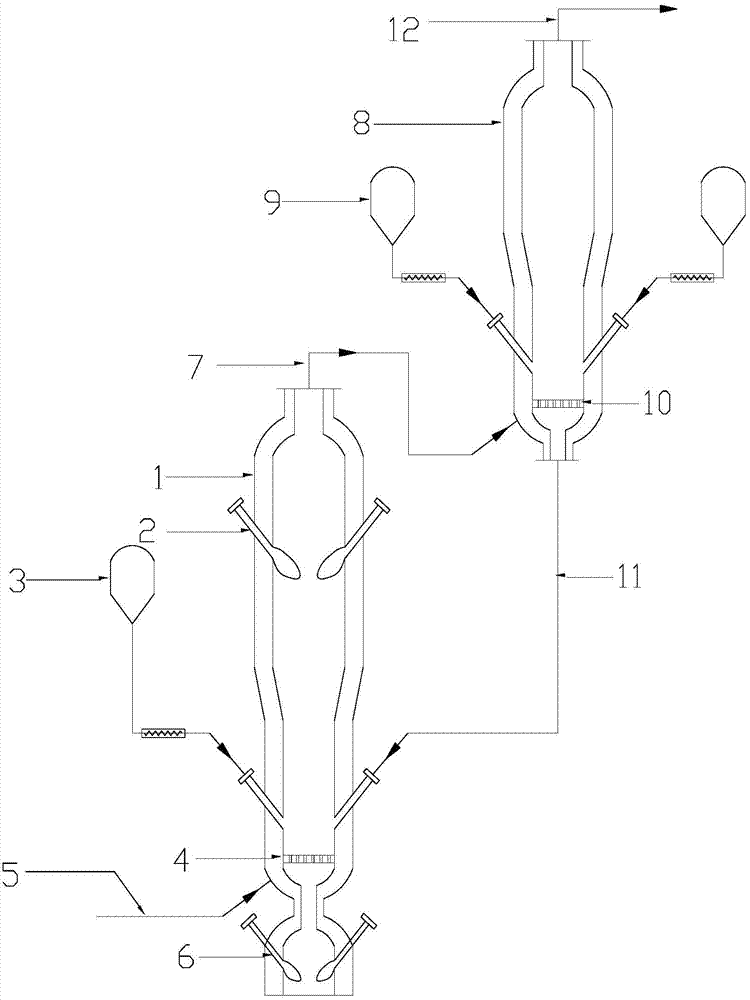

[0031] Urban waste in my country generally has high water content and low calorific value. In order to make the research of this example more universal, waste with a calorific value of 1250kcal / kg was selected for design, and the daily processing capacity was 100t / d. The invention provides a plasma garbage gasification-pyrolysis equipment, which includes two subsystems, a gasification system and a pyrolysis system, and the pyrolysis system is connected to the gasification system through circulating materials. The gasification system includes a furnace body (1) and a gasification system. Plasma torches (2), (6); by adjusting the power and quantity of the plasma torches (2), (6), the temperature of the gasification furnace (1) is 900-1300°C, and the temperature of the pyrolysis furnace is 700-900°C.

[0032] A kind of plasma waste gasification-pyrolysis equipment, it comprises the following steps:

[0033] Step 1): Domestic garbage (80t / d) enters the gasification furnace body 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com