Domestic refuse plasma gasification reaction furnace

A technology of gasification reaction and domestic waste, which is applied in the manufacture of combustible gas, solid waste removal, petroleum industry, etc. It can solve the problems of increased operating costs, increased equipment costs, and easy cracking, so as to improve space utilization and reduce waste. Power consumption, the effect of solving uneven heating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

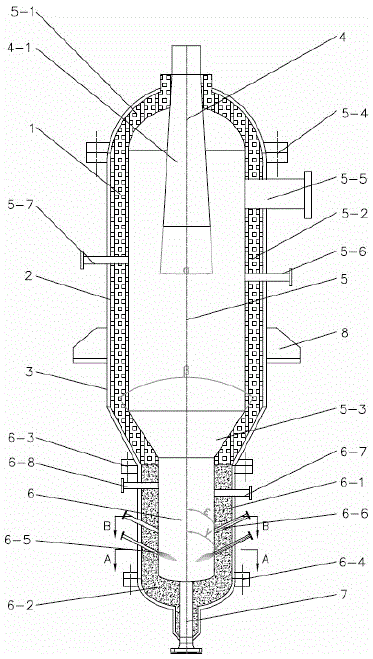

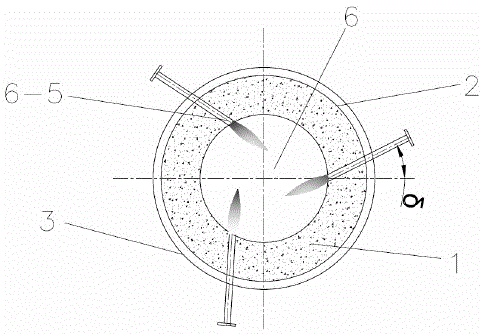

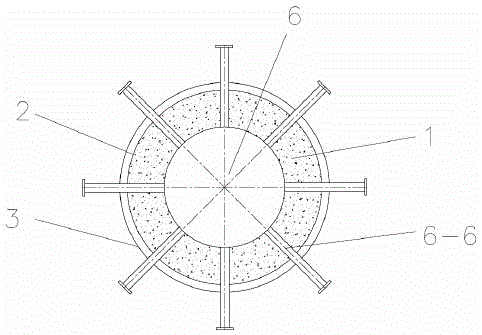

[0033] Such as Figure 1-3As shown, a domestic garbage plasma gasification reaction furnace includes an upper pyrolysis gasification reaction chamber 5 and a lower ash melting chamber 6 connected up and down. It is circular; the pyrolysis gasification reaction chamber 5 is longitudinally divided into an upper head 5-1, a middle cylinder 5-2 and a bottom cone 5-3, and the upper head 5-1 is embedded with a garbage Inlet 4, garbage inlet 4 is a long and narrow tapered pipe 4-1, the upper part of the middle cylinder 5-2 is provided with synthesis gas outlet 5-5, and the installation height of synthesis gas outlet 5-5 is higher than the cone of garbage inlet 4 The bottom plane of the tube 4-1; the ash melting chamber 6 includes a cylinder 6-1 and a bottom head 6-2, and a plurality of plasma torches on the same horizontal plane are evenly arranged on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com