Three-way catalyst and preparation method thereof

A technology of three-way catalyst and cross-linking agent, which is applied in chemical instruments and methods, physical/chemical process catalysts, separation methods, etc., can solve the problems of increasing the manufacturing and use costs of three-way catalysts, difficult to recover precious metals, and expensive precious metals, etc. Achieve the effect of delaying carbon deposition, improving thermal stability and delaying the loss of active components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

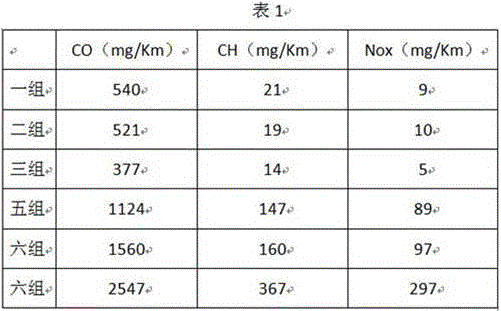

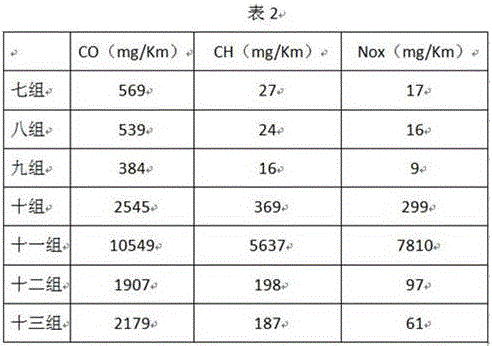

Embodiment 1

[0020] A three-way catalyst comprising the following raw materials: 2 parts lanthanum chloride, 2 parts scandium chloride, 5 parts polyvinylpyrrolidone, 21 parts titanium dioxide, 16 parts ceramics, 16 parts silica gel, 2 parts sodium sulfate, sulfuric acid 5 parts of palladium, 6 parts of cerium chloride, 17 parts of zirconium dioxide, γ-Al 2 O 3 17 parts, 2 parts crosslinking agent, the preparation method of the three-way catalyst is: dissolve lanthanum chloride, scandium chloride and polyvinylpyrrolidone in water, then add titanium dioxide, ceramics and silica gel, and immerse for 1.1h at room temperature. Add a cross-linking agent for cross-linking for 0.6 hours. The cross-linked material is prepared into microspheres that can pass through a 60-mesh sieve with a high-pressure forming apparatus. The microspheres are denoted as A, and A is placed in a 0.1 mol / L sodium hydroxide solution Soak in medium for 12 minutes to obtain porous microspheres as B. Use deionized water to cl...

Embodiment 2

[0022] A three-way catalyst comprising the following raw materials: 9 parts of lanthanum chloride, 9 parts of scandium chloride, 7 parts of polyvinylpyrrolidone, 28 parts of titanium dioxide, 18 parts of ceramics, 18 parts of silica gel, 4 parts of sodium sulfate, and sulfuric acid 7 parts of palladium, 6 parts of cerium chloride, 24 parts of zirconium dioxide, γ-Al 2 O 3 18 parts, 4 parts crosslinking agent, the preparation method of the three-way catalyst is: dissolve lanthanum chloride, scandium chloride and polyvinylpyrrolidone in water, then add titanium dioxide, ceramics and silica gel, and immerse for 1.8h at room temperature. Add a cross-linking agent to cross-link for 0.9h. The cross-linked material is prepared into microspheres that can pass through a 60-mesh sieve with a high-pressure molding machine. The microspheres are denoted as A, and A is placed in a 0.1 mol / L sodium hydroxide solution Soak the microspheres in medium for 28 minutes to obtain the porous microsphe...

Embodiment 3

[0024] A three-way catalyst comprising the following raw materials: 5 parts of lanthanum chloride, 5 parts of scandium chloride, 6 parts of polyvinylpyrrolidone, 25 parts of titanium dioxide, 20 parts of ceramics, 20 parts of silica gel, 3 parts of sodium sulfate, and sulfuric acid 6 parts of palladium, 7 parts of cerium chloride, 20 parts of zirconium dioxide, γ-Al 2 O 3 18 parts, 3 parts crosslinking agent, the preparation method of the three-way catalyst is: dissolve lanthanum chloride, scandium chloride and polyvinylpyrrolidone in water, then add titanium dioxide, ceramics and silica gel, and immerse for 1.5h at room temperature. Add a cross-linking agent for cross-linking for 0.8 hours. The cross-linked material is prepared into microspheres that can pass through a 60-mesh sieve with a high-pressure molding machine. The microspheres are denoted as A, and A is placed in a 0.1 mol / L sodium hydroxide solution Soak in medium for 20 minutes to obtain porous microspheres as B. Us...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com