Method for chlorinating and electrolyzing bauxite to prepare alumina and comprehensively utilizing bauxite

A bauxite and alumina technology, applied in chemical instruments and methods, alumina/aluminum hydroxide, iron oxide, etc., can solve the problems of high energy consumption, inability to comprehensively utilize, long process, etc., and achieve high product purity, Improve resource utilization and reduce the effect of processing links

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

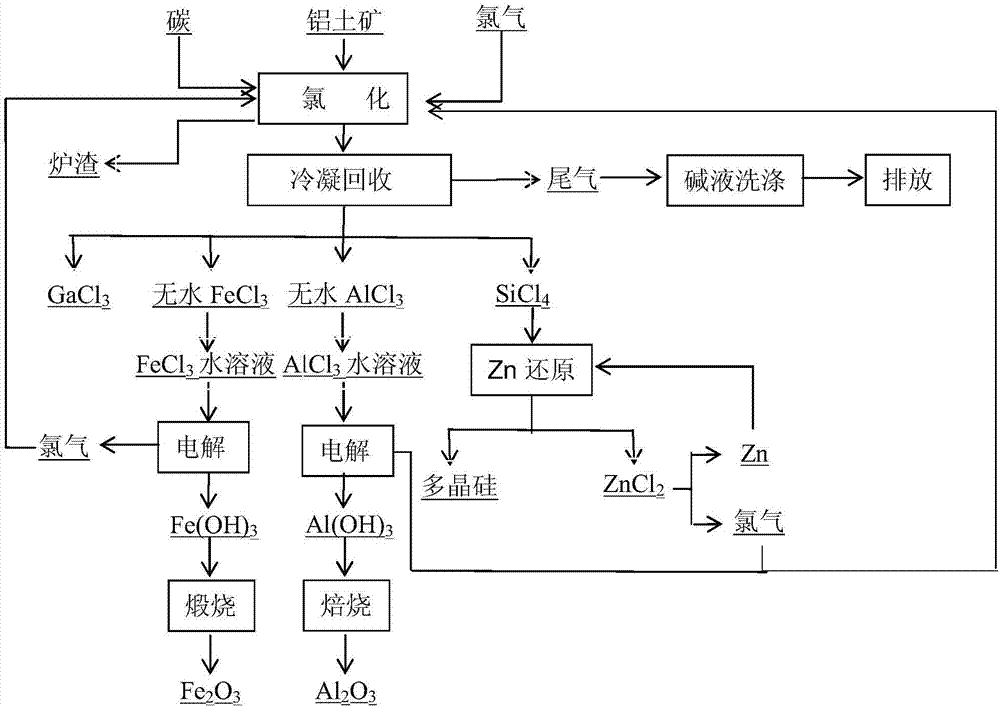

[0060] A method for preparing alumina and its comprehensive utilization by chlorination electrolysis of bauxite, the process flow chart of which is as follows figure 1 As shown, it specifically includes the following steps:

[0061] (1) Chlorination separation of bauxite:

[0062] After adding carbon to the bauxite and mixing, pass into chlorine gas, and carry out chlorination reaction by microwave heating; wherein, the addition amount is by mass ratio, bauxite: carbon = 1: 0.2, and the chlorination reaction temperature is 600 ℃, after the chlorination reaction, use a rectification device, set different condensation temperatures according to the different boiling points of each material, and separate them to obtain anhydrous aluminum chloride, anhydrous ferric chloride, silicon tetrachloride, titanium tetrachloride, scandium chloride and gallium chloride, while the exhaust gas is washed and discharged with alkali solution; among them, the separated gallium chloride is enriche...

Embodiment 2

[0080] A method for preparing alumina and its comprehensive utilization by chlorination electrolysis of bauxite, the process flow chart of which is as follows figure 1 As shown, it specifically includes the following steps:

[0081] (1) Chlorination separation of bauxite:

[0082] After adding carbon to the bauxite and mixing, pass into chlorine gas, and carry out chlorination reaction by microwave heating; wherein, the addition amount is by mass ratio, bauxite: carbon = 1: 0.2, and the chlorination reaction temperature is 700 ℃, after the chlorination reaction, use a rectification device, set different condensation temperatures according to the different boiling points of each material, and separate them to obtain anhydrous aluminum chloride, anhydrous ferric chloride, silicon tetrachloride, titanium tetrachloride, scandium chloride and gallium chloride, while the exhaust gas is washed and discharged with alkali solution; among them, the separated gallium chloride is enriche...

Embodiment 3

[0100] A method for preparing alumina and its comprehensive utilization by chlorination electrolysis of bauxite, the process flow chart of which is as follows figure 1 As shown, it specifically includes the following steps:

[0101] (1) Chlorination separation of bauxite:

[0102]After adding carbon to the bauxite and mixing, pass into chlorine gas, and carry out chlorination reaction by microwave heating; wherein, the addition amount is by mass ratio, bauxite: carbon = 1: 0.3, and the chlorination reaction temperature is 750 ℃, after the chlorination reaction, use a rectification device, set different condensation temperatures according to the different boiling points of each material, and separate them to obtain anhydrous aluminum chloride, anhydrous ferric chloride, silicon tetrachloride, titanium tetrachloride, scandium chloride and gallium chloride, while the exhaust gas is washed and discharged with alkali solution; among them, the separated gallium chloride is enriched...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com