Fully-mixed granulated feed for sheep raised for cashmere, wool, and meat, and processing method thereof

A technology for pellet feed and meat sheep, applied in animal feed, animal feed, application, etc., can solve the problems of inconvenient storage and transportation, low digestibility, high cost, etc., achieve simple and low processing, improve digestibility, and low production cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

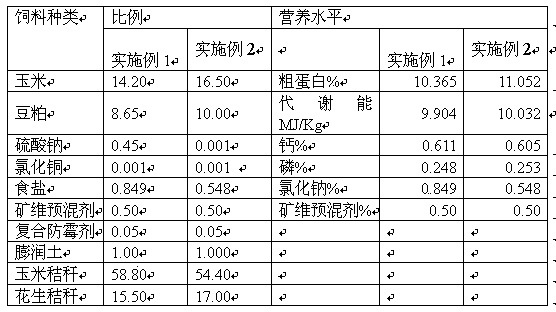

[0019] Example 1, the percentages of the total weight of the ingredients in the formula are: 14.20% of corn, 8.65% of soybean meal, 0.45% of sodium sulfate, 0.001% of copper chloride, 0.849% of table salt, 0.50% of mineral dimension premix, compound anti Mold agent 0.05%, bentonite 1.00%, corn straw 58.80%, peanut straw 15.50%. The feed formulated according to the weight percentage is suitable for cashmere goats to eat during non-special physiological periods.

Embodiment 2

[0020] Example 2, the percentages of the total weight of the ingredients in the formula are: corn 16.50%, soybean meal 10.00%, sodium sulfate 0.001%, copper chloride 0.001%, salt 0.548%, mineral dimension premix 0.50%, composite anti Mold agent 0.05%, bentonite 1.00%, corn straw 54.40%, peanut straw 17.00%. The feed formulated according to this weight percentage is suitable for sheep and meat sheep to eat during non-special physiological periods

[0021] The mineral dimension premix is a commercially available Fanxing mineral dimension premix.

[0022] The processing method of the whole mixed pellet feed for cashmere, wool and meat sheep is as follows:

[0023] a. Processing method of corn stalks, peanut stalks and other raw materials: Fill corn stalks and peanut stalks into a hammer mill for crushing. The aperture of the sieve plate is 1~2.5 mm;

[0024] b. Premix mixing method: Weigh table salt, mineral dimension premix, compound antifungal agent, sodium sulfate, copper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com