Method for preparing scandium oxide with various morphologies by liquid phase precipitation method

A technology of liquid phase precipitation and scandium oxide, which is applied in the fields of chemical instruments and methods, rare earth metal oxides/hydroxides, inorganic chemistry, etc., can solve the problem that the shape of scandium oxide powder material is difficult to control, etc., and the method is simple and effective, Effects with strong maneuverability and easy control of conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

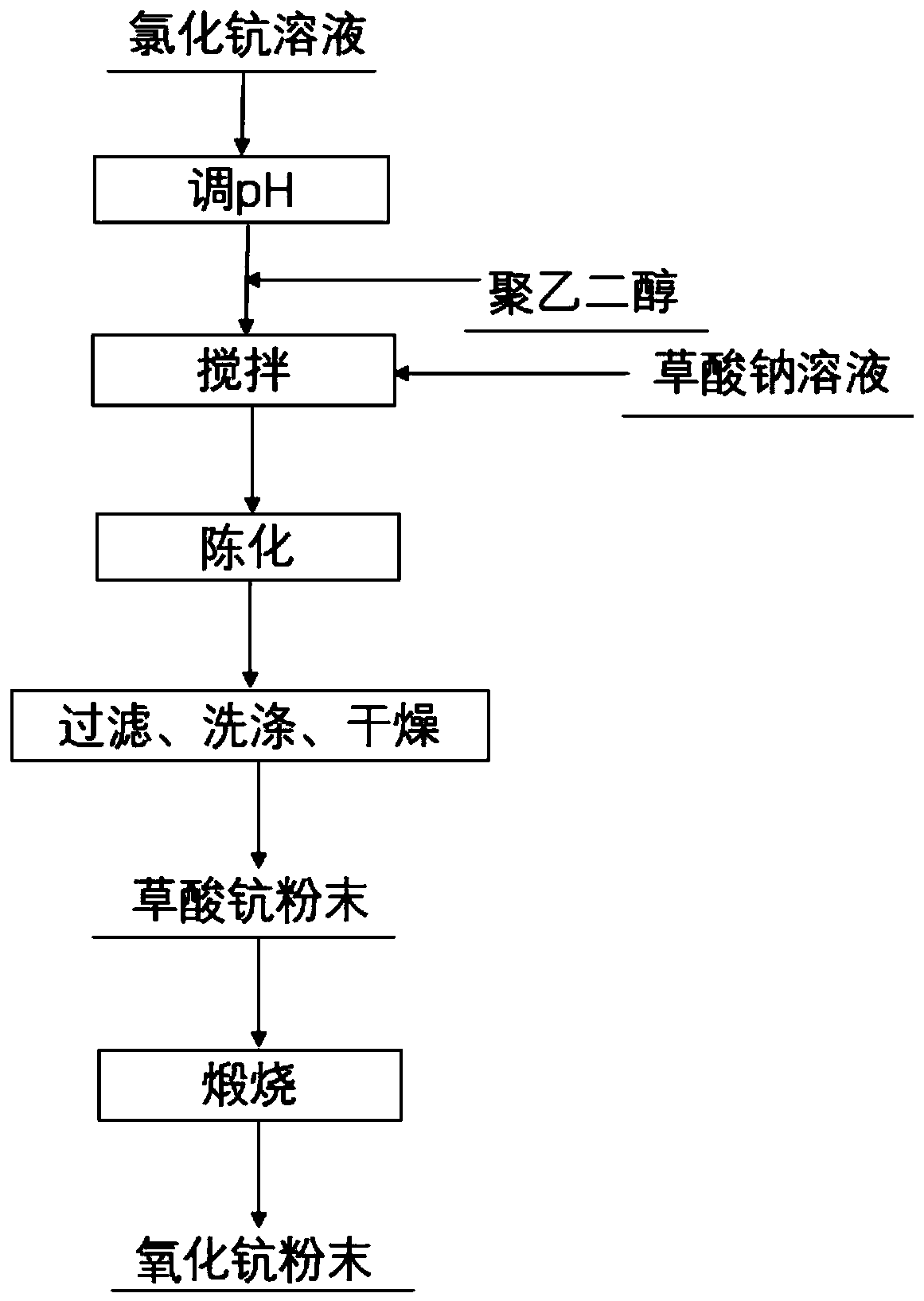

[0032] Example 1: Please refer to figure 1 , using scandium chloride solution as the raw material, adding HCl to adjust the pH to 0.5, adding polyethylene glycol with a mass of 1% of the mass of the raw material, and adding the same volume of sodium oxalate solution as the raw material in a dropwise manner, wherein the concentration of sodium oxalate It is 2.25 times the concentration of scandium ions in the raw material. After 2 hours of stirring and 24 hours of aging, the precursor is obtained. The precursor is filtered, washed and dried by natural filtration, and calcined at 720 ° C for 2 hours to obtain oxidation Scandium powder. Observed by scanning electron microscope, the morphology of scandium oxide powder material is layered accumulation of quadrangular flakes.

Embodiment 2

[0033] Embodiment 2: using scandium chloride solution as raw material, adding HCl to adjust the pH to 1.6, adding a sodium oxalate solution with the same volume as the raw material in a dropwise manner, wherein the concentration of sodium oxalate is 1.5 times the concentration of scandium ions in the raw material , After 2 hours of stirring and 24 hours of aging, the precursor was obtained. The precursor was filtered, washed and dried by natural filtration, and calcined at 800 ° C for 2 hours to obtain scandium oxide powder. Observed by a scanning electron microscope, the scandium oxide powder material has a hexagonal sheet shape.

Embodiment 3

[0034] Embodiment three: take scandium chloride solution as raw material, add the sodium oxalate solution with the same volume of raw material in the mode of dripping, wherein, the concentration of sodium oxalate is 2.25 times of the concentration of scandium ion in the raw material, after 2 hours of stirring and After aging for 24 hours, the precursor was obtained. The precursor was filtered, washed and dried by natural filtration, and calcined at 800° C. for 2 hours to obtain scandium oxide powder. Observed by scanning electron microscope, the morphology of scandium oxide powder material is amorphous fragments.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com