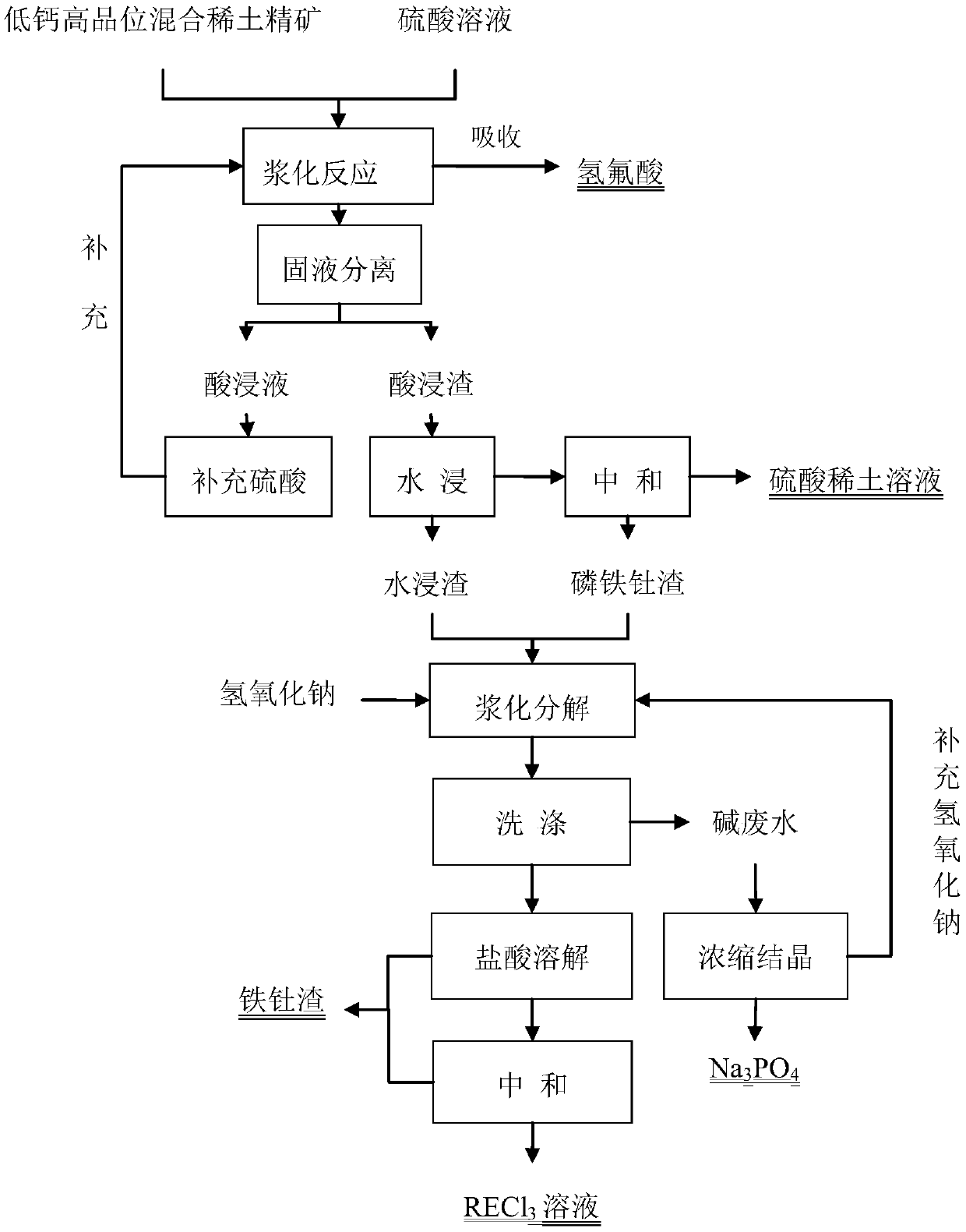

Method for low-calcium high-grade mixed type rare-earth concentrate circulating slurrying decomposition

A mixed rare earth, high-grade technology, applied in the direction of rare earth metal compounds, rare earth metal halides, chemical instruments and methods, etc., can solve problems such as equipment looping, achieve the effects of inhibiting dissolution, solving equipment technical problems, and solving equipment looping Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029]100g of REO is 65.7%, CaO is 2.86% mixed rare earth concentrate and mass percent is 70% sulfuric acid solution is mixed according to liquid-solid ratio 3:1 (sulfuric acid: mineral weight ratio is 3.4:1), stirring and heating Insulate at 150°C for 0.5h, and the tail gas is condensed and absorbed to produce by-products of fluorine and silicon mixed acid. After the reaction and solid-liquid separation, the acid leaching slag was leached twice with 1500mL of water, and the water leaching solution was neutralized to form iron phosphorus thorium slag and REO concentration of 31.6g / L rare earth sulfate solution. Calculated by F in water leaching residue, the decomposition rate of fluorine-containing minerals is 97.4%. The acid leaching liquid continues to replenish concentrated sulfuric acid with a mass percentage of 98% to 70%, and then circulates the second batch of concentrate. Keep the reaction temperature, acid amount, acid concentration, reaction time, etc. under the sam...

Embodiment 2

[0032] 100g of REO is 65.7%, CaO is 2.86% mixed rare earth concentrate and mass percent is 40% sulfuric acid solution is mixed according to liquid-solid ratio 3:1 (sulfuric acid: mineral weight ratio is 1.6:1), stirring and heating Insulate at 110°C for 5 hours, and the tail gas is condensed and absorbed to produce by-products of fluorine and silicon mixed acid. After the reaction and solid-liquid separation, the acid leaching slag was leached twice with 1500mL of water, and the water leaching solution was neutralized to form iron phosphorus thorium slag and REO concentration of 21.5g / L rare earth sulfate solution. Calculated by F in water leaching residue, the decomposition rate of fluorine-containing minerals is 73.4%. The acid leaching liquid continues to replenish concentrated sulfuric acid with a mass percentage of 98% to 40%, and then circulates the second batch of concentrate. Keep the reaction temperature, acid amount, acid concentration, reaction time, etc. under the...

Embodiment 3

[0035] Mix 100g of mixed rare earth concentrate with 67.9% REO and 1.96% CaO and 70% sulfuric acid solution at a liquid-solid ratio of 4.5:1 (sulfuric acid:mineral weight ratio is 5:1), stir and heat Insulate at 130°C for 1.5h, and the tail gas is condensed and absorbed to produce by-products of fluorine and silicon mixed acid. After the reaction and solid-liquid separation, the acid leaching slag was leached twice with 1500mL of water, and the water leaching solution was neutralized to form iron phosphorus thorium slag and REO concentration of 33.1g / L rare earth sulfate solution. Calculated by F in water leaching residue, the decomposition rate of fluorine-containing minerals is 96.7%. The acid leaching liquid continues to replenish concentrated sulfuric acid with a mass percentage of 98% to 70%, and then circulates the second batch of concentrate. Keep the reaction temperature, acid amount, acid concentration, reaction time, etc. under the same conditions as the first time,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com