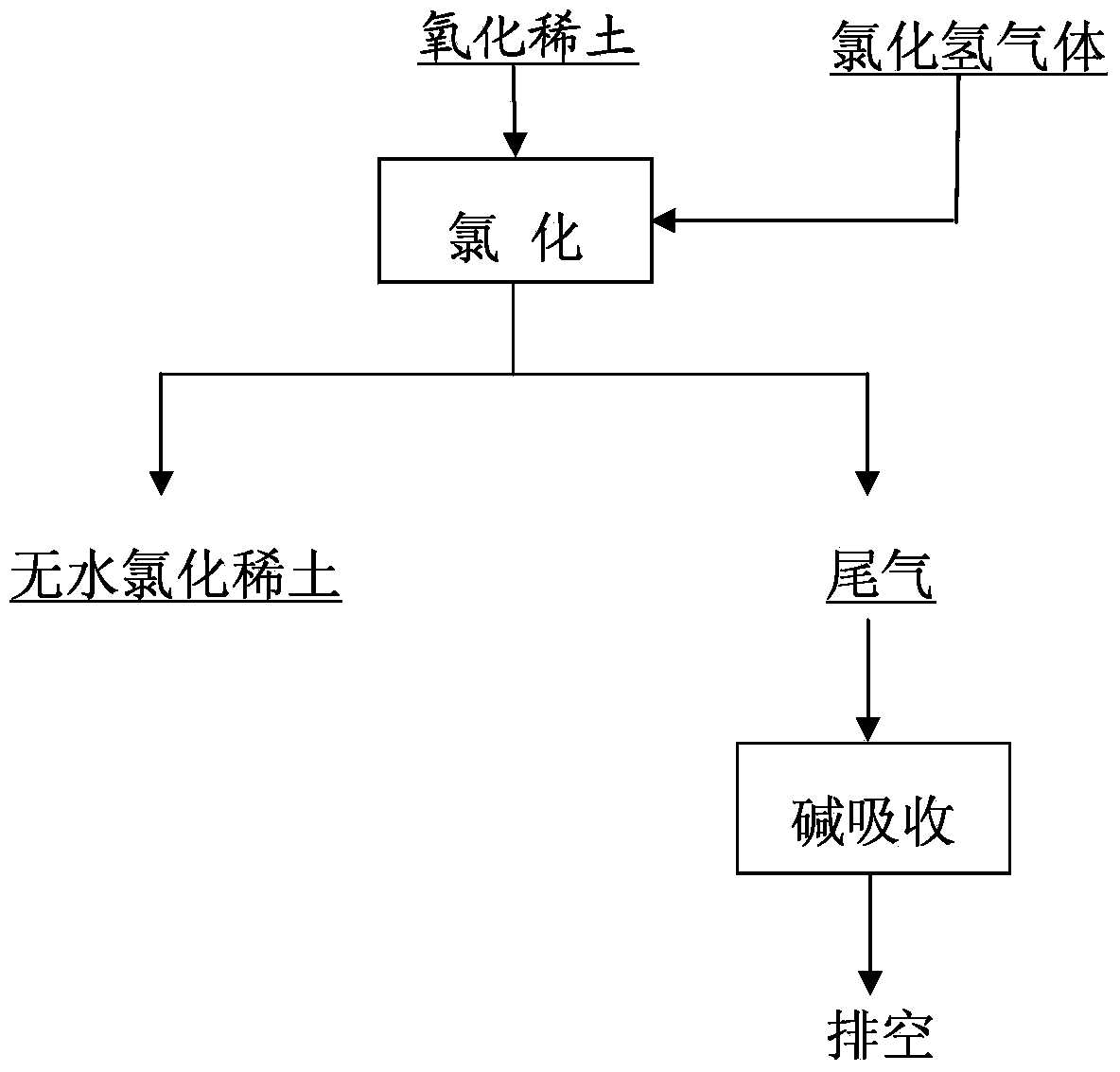

Method and device for preparing anhydrous rare earth chloride through gas phase method

A technology of water chlorination and gas phase method, applied in chemical instruments and methods, inorganic chemistry, rare earth metal compounds, etc., can solve the problems of serious ammonia volatilization, large energy consumption, long process flow, etc., so as to inhibit the production of rare earth oxychloride , easy to produce on industrial scale, simple process and equipment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

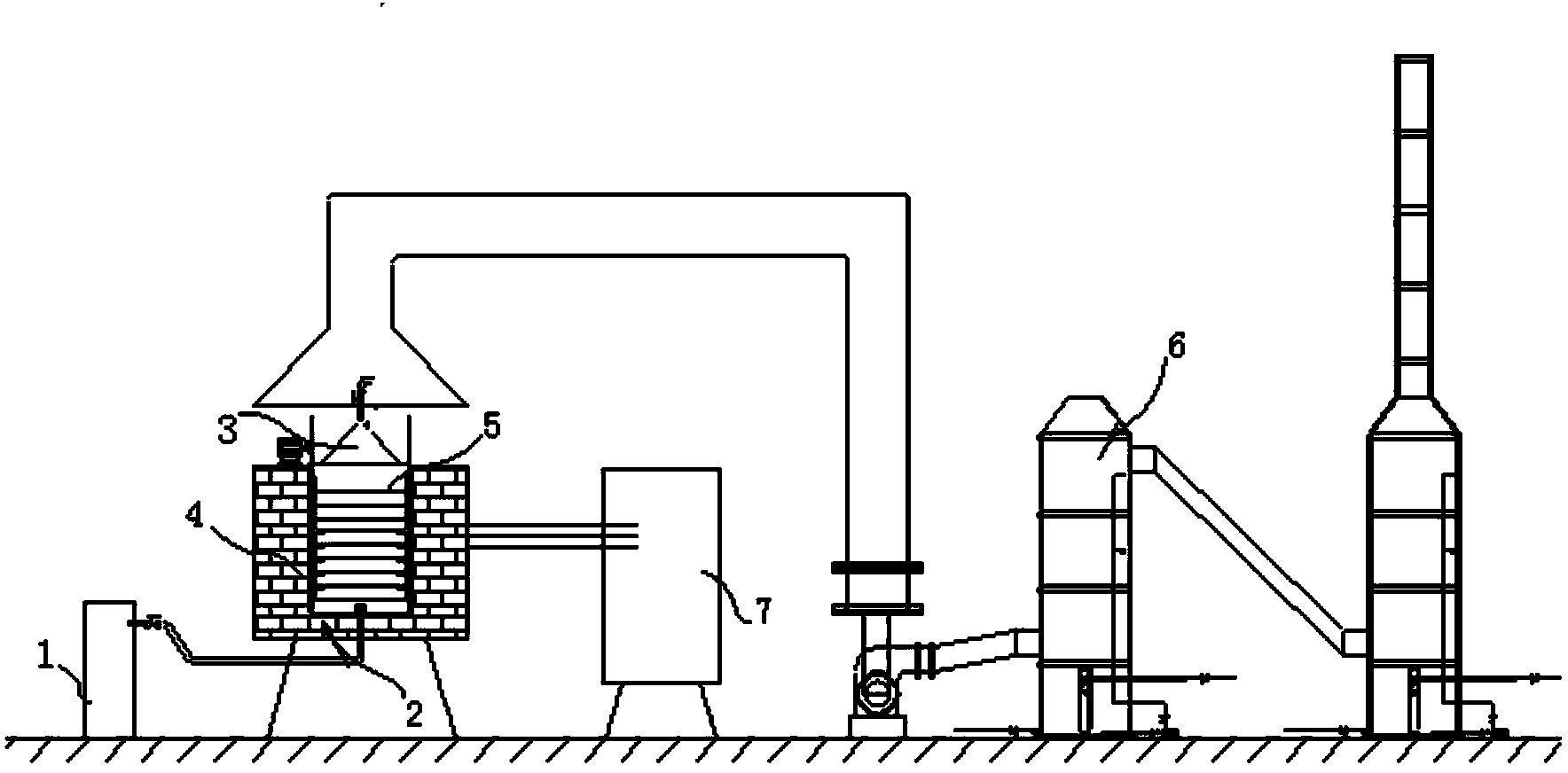

Embodiment 1

[0034] Embodiment 1: lanthanum oxide 120Kg is packed in the container 4 with holes, on the material tray 5, the thickness of the material layer is 8cm, the container is put into the chlorination furnace 2, heated to 400°C, and the chlorine is introduced through the air inlet device 3 HCl gas was introduced into the chemical furnace 2, the temperature was kept for 27 hours, the heating was stopped, and the temperature of the chlorination furnace was allowed to cool down naturally. When the temperature dropped below 100°C, the chlorination furnace was opened, and the chlorinated rare earth chloride was taken out, and vacuum-packed to obtain 178.65Kg of anhydrous lanthanum chloride, after analysis and inspection, the purity of anhydrous lanthanum chloride is 98.00%. The hydrogen chloride tail gas generated in the chlorination furnace enters the acid mist absorption tower 6 through the gas outlet device 3 to be absorbed and then emptied. The whole system is controlled by an automa...

Embodiment 2

[0035] Embodiment 2: lanthanum oxide 120Kg is packed in the container with holes, on the material tray 5, the thickness of the material layer is 10cm, the container is put into the chlorination furnace, heated to 600°C, and the chlorination furnace is started through the air inlet device 3 HCl gas was introduced into the chlorination furnace, kept warm for 22.5 hours, stopped heating, and let the chlorination furnace cool down naturally. When the temperature dropped below 100°C, open the chlorination furnace, take out the chlorinated rare earth chloride, and vacuum pack it to obtain 177.96Kg of Anhydrous lanthanum chloride, after analysis and inspection, the purity of anhydrous lanthanum chloride is 98.5%. The hydrogen chloride tail gas generated in the chlorination furnace enters the acid mist absorption tower 6 through the gas outlet device 3 to be absorbed and then emptied. The whole system is controlled by an automatic control device 7 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com