Preparation method of anhydrous yttrium chloride

A technology of yttrium chloride and ammonium chloride, applied in chemical instruments and methods, inorganic chemistry, rare earth metal chlorides, etc., can solve the problems that it is difficult to obtain pure anhydrous rare earth chloride, unfavorable for industrial production, unsuitable for industrial production, etc. , to achieve the effect of safe and effective production method, high yield of reaction product and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

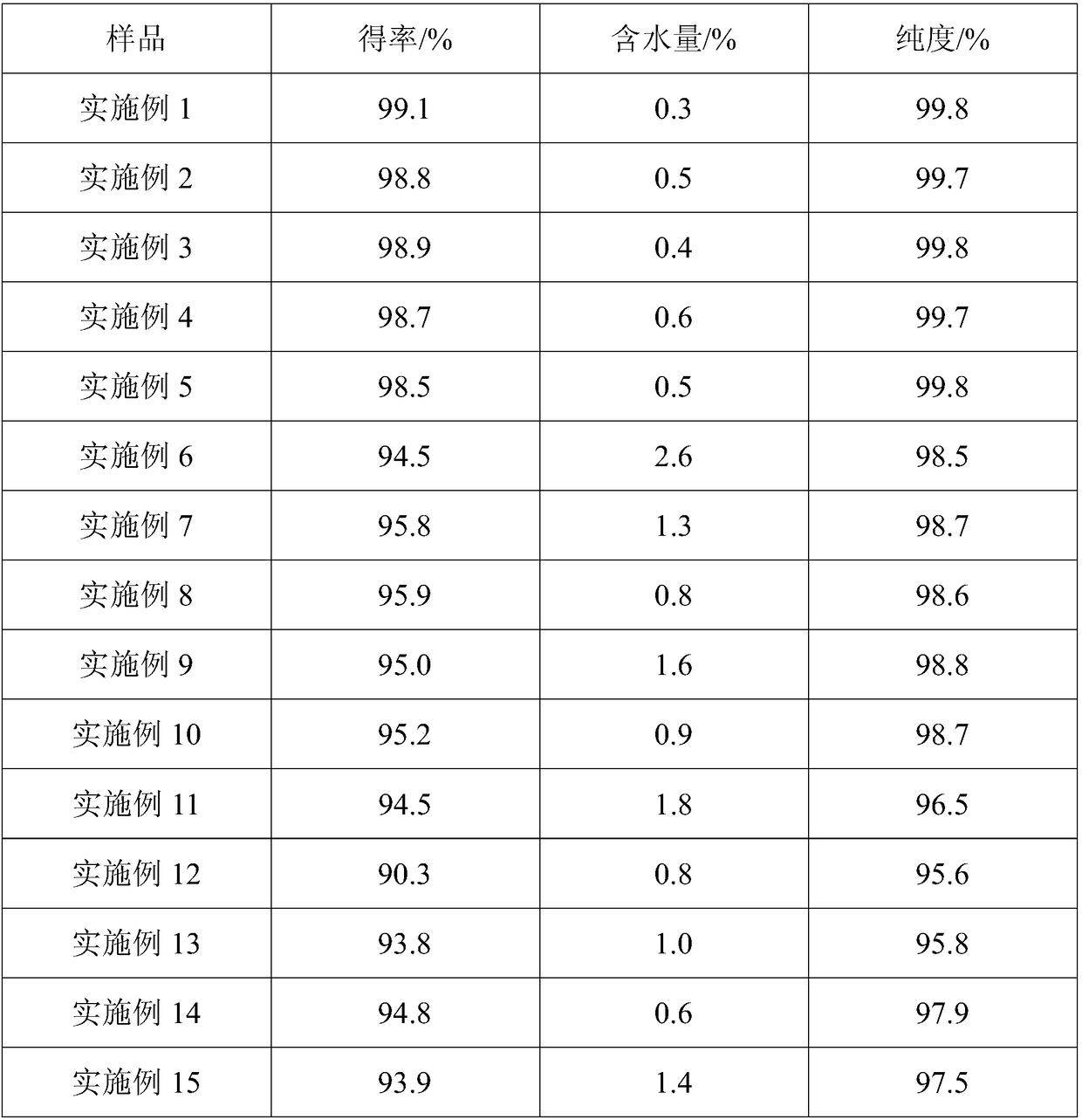

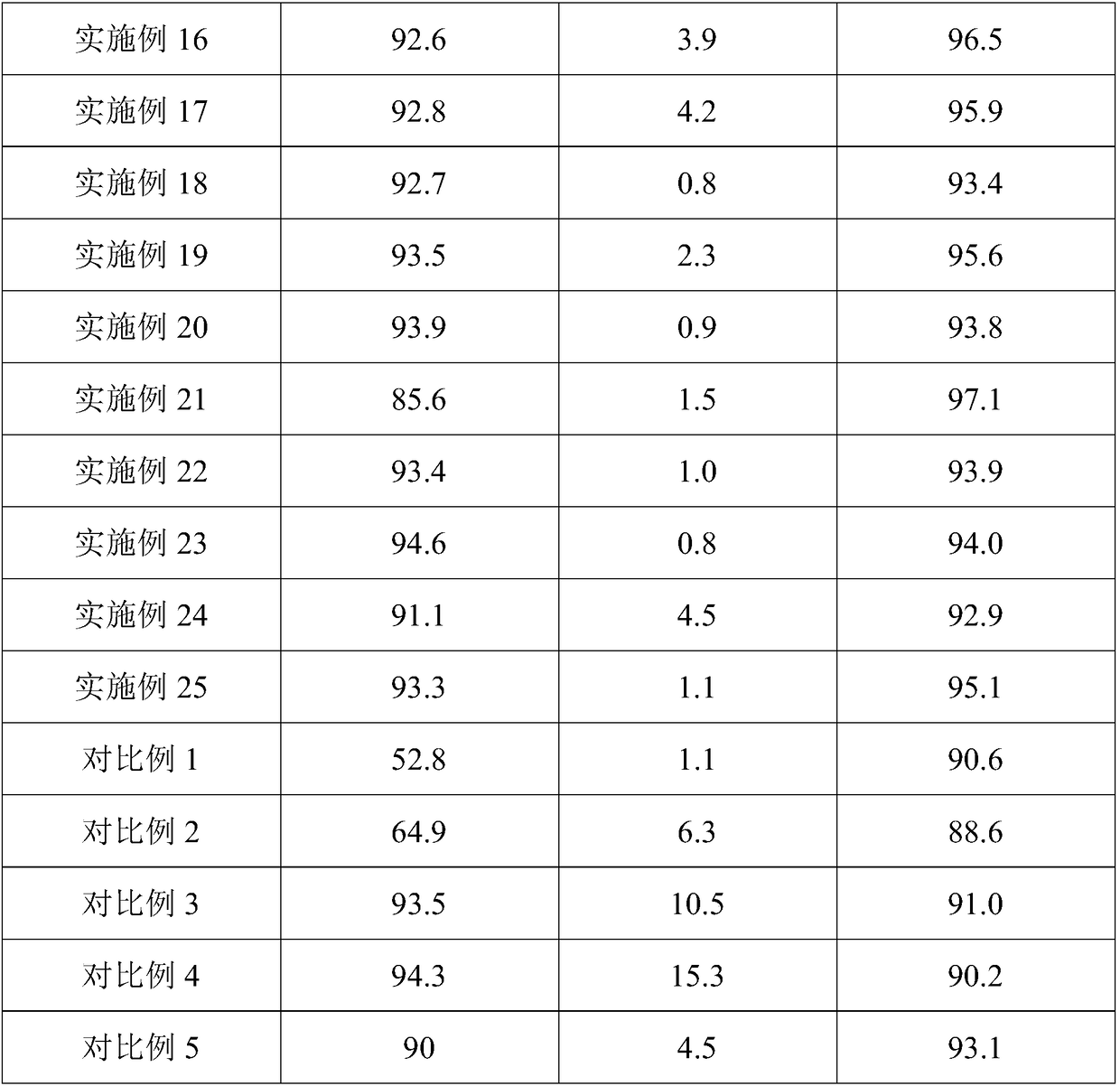

Examples

Embodiment 1

[0054] (1) pretreatment: yttrium oxide is pulverized through a 150-mesh sieve, and ammonium chloride is pulverized through a 150-mesh sieve;

[0055] (2) The ammonium chloride is tiled on the bottom of the reaction device, the tile thickness is 10cm, and the yttrium oxide is tiled on the ammonium chloride solid, and the mass ratio of the yttrium oxide to the ammonium chloride is 1:1.5;

[0056] (3) Gradient heating, the heating rate is 20°C / min, stop heating when the temperature reaches 240°C, constant temperature reaction, constant temperature reaction time is 4.5h;

[0057] (4) Feed dry hydrogen chloride gas after 2 hours from the start of the constant temperature reaction, and the ventilation rate is 0.7L / min;

[0058] (5) The reaction product obtained in step (4) is fluidized and dried under an argon atmosphere, and the inlet air temperature is 180° C., and fluidized and dried for 3 hours;

[0059] (6) Dry the product obtained in step (5) for 6 hours at a temperature of 2...

Embodiment 2

[0061] (1) pretreatment: yttrium oxide is pulverized through a 160 mesh sieve, and ammonium chloride is pulverized through a 140 mesh sieve;

[0062] (2) The ammonium chloride is tiled on the bottom of the reaction device, the tile thickness is 12cm, and the yttrium oxide is tiled on the ammonium chloride solid, and the mass ratio of the yttrium oxide to the ammonium chloride is 1:1.2;

[0063] (3) Gradient heating, the heating rate is 22 ° C / min, stop heating when the temperature reaches 250 ° C, constant temperature reaction, constant temperature reaction time is 5h;

[0064] (4) Pass into dry hydrogen chloride gas after the constant temperature reaction starts 3h, and the ventilation rate is 0.8L / min;

[0065] (5) The reaction product obtained in step (4) is fluidized and dried under a nitrogen atmosphere, and the inlet air temperature is 190° C., and fluidized and dried for 2 hours;

[0066] (6) Dry the product obtained in step (5) for 5 hours at a temperature of 230° C...

Embodiment 3

[0068] (1) pretreatment: yttrium oxide is pulverized through a 140 mesh sieve, and ammonium chloride is pulverized through a 130 mesh sieve;

[0069] (2) The ammonium chloride is tiled on the bottom of the reaction device, the tile thickness is 8cm, and the yttrium oxide is tiled on the ammonium chloride solid, and the mass ratio of the yttrium oxide to the ammonium chloride is 1:0.5;

[0070] (3) Gradient heating, the heating rate is 15°C / min, stop heating when the temperature reaches 220°C, constant temperature reaction, constant temperature reaction time is 4h;

[0071] (4) 1 hour after the start of the constant temperature reaction, dry hydrogen chloride gas is introduced, and the ventilation rate is 0.5L / min;

[0072] (5) The reaction product obtained in step (4) is fluidized and dried under a helium atmosphere, and the inlet air temperature is 160° C., and fluidized and dried for 1 hour;

[0073] (6) Dry the product obtained in step (5) for 4 hours at a temperature of 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com