Appliance for turnover of automobile auxiliary instrument board assemblies

A technology for sub-dashboards and appliances, applied in the field of auto parts packaging, can solve the problems of unconformity with ergonomics, visualization, and low work efficiency, and achieve the effects of eliminating economic losses, improving operations, and reducing transportation and storage costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

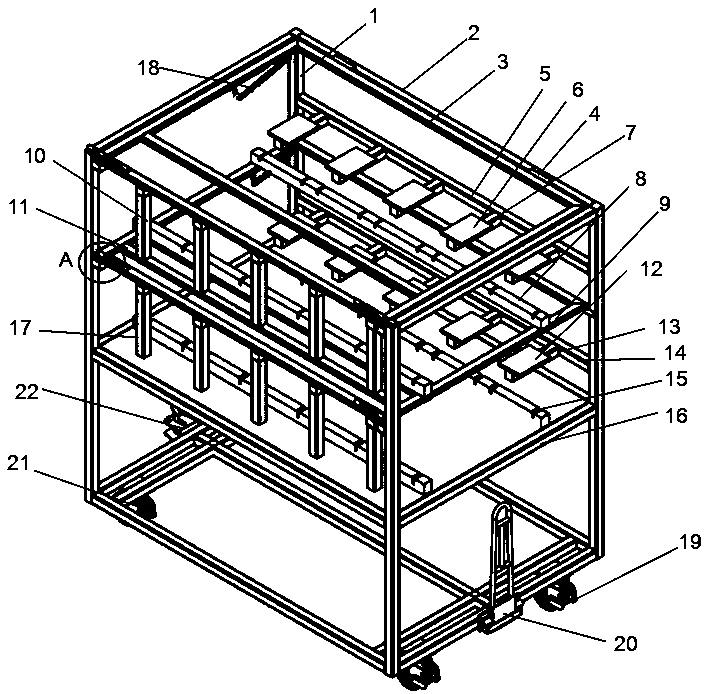

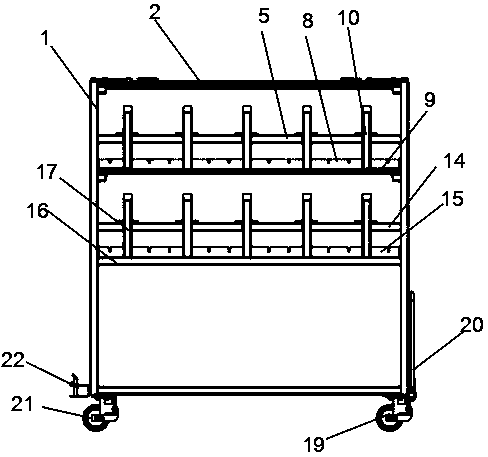

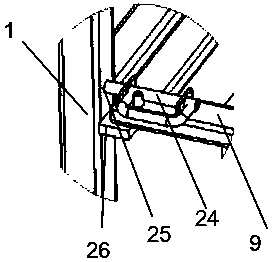

[0041] Combine below Figure 1-Figure 5 To describe in detail the specific working conditions proposed by the present invention, an appliance for a turnaround automobile sub-dashboard assembly, the appliance includes an appliance body, a movement mechanism, a placement layer and a top cover 3 .

[0042] The appliance body is formed by welding the beams and columns on the side and the back side, its top is welded to the main column 1 by the main beam 2 , and its base is welded to the main column 1 by the base beam. The beams and columns are made of Q235 and shaped as rectangular square tubes. The rectangular square tube as the main structure of the appliance body can not only meet the strength requirements of the appliance, but compared with the whole surface material similar to wooden boxes, the present invention can save material and realize visualization, that is, the staff can use it without opening the appliance. The quantity and condition of the car sub-dashboard assembl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com