Short-process rolling method for cold-rolled 5052 alloy tank cover material

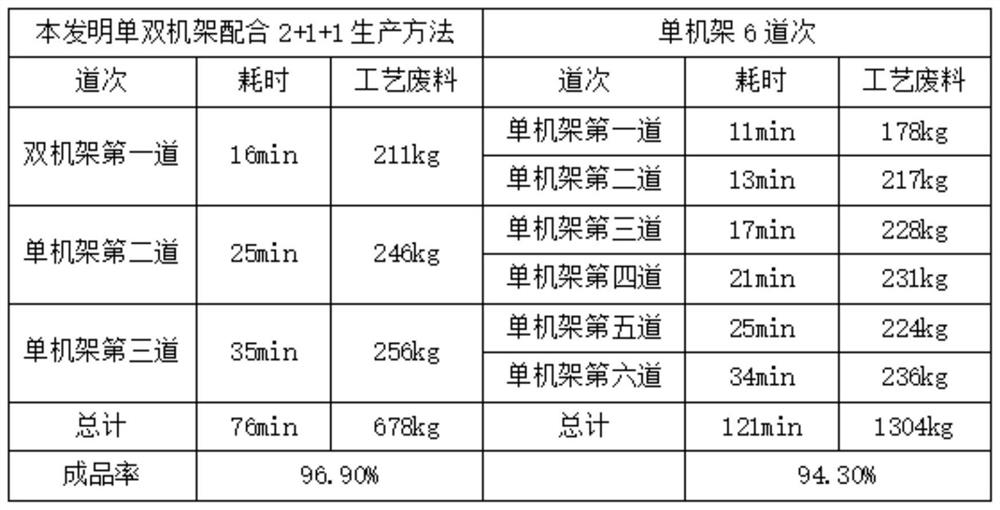

A short process, can lid technology, applied in metal rolling and other directions, can solve the problems of low production efficiency, many rolling process waste, and low yield.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0022] refer to figure 1 , is a short-flow rolling method for cold-rolling 5052 alloy can lid material disclosed by the present invention, including casting and rolling. The cast-rolled coil is formed after a series of steps such as heating, annealing, edge trimming and coiling of the raw material of the strip, and hot continuous rolling by a rolling mill. According to the national production standard, the plate thickness of the cast-rolled coil used to produce the 5052 alloy can cover is generally 2.7-3.0mm, and the specification of 3.0mm is selected in this embodiment. Prepare the cold rolling mill required for unwinding collective rolling in advance, and check whether the equipment is working normally. After the preparation work is completed, start the cold rolling process. The cold rolling process includes the following steps:

[0023] Double-stand blan...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com