3003H14 aluminum alloy sheet and production method thereof

A technology of aluminum alloy plate and production method, which is applied in the field of aluminum alloy manufacturing, can solve the problems that the surface quality cannot meet the requirements of high-end products, the surface quality cannot meet the requirements of high-end products, and the temperature control of the annealing furnace is poor, so as to save cold rolling and annealing Process, save production time, improve the effect of surface and shape quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] A chemical composition of a 3003H14 aluminum alloy plate: by mass percentage, Si: 0.063%, Fe 0.455%, Cu: 0.079%, Mn: 1.097%, Mg: 0.008%, Cr: 0.045%, Zn: 0.006%, Ti : 0.017%, other impurities ≤ 0.01%, all impurities ≤ 0.15%, the balance is Al;

[0033] A production method of 3003H14 aluminum alloy plate, using aluminum ingot as raw material, through melting and casting, sawing, face milling, ingot heating, hot rolling (hot rough rolling, hot finish rolling), cold rolling, cleaning and straightening and cross shearing ,Specific steps are as follows:

[0034] 1) Melting and casting: Aluminum ingots are used as raw materials to obtain ingots after melting and casting. The melting temperature is 730°C, the refining temperature is 725°C, and the casting temperature is 685°C;

[0035] 2) Heating the ingot obtained in step 1) after sawing and face milling, the heating temperature of the ingot is 510°C, and the holding time is 4h;

[0036] 3) Hot rolling: use four-high reversi...

Embodiment 2

[0044] A chemical composition of a 3003H14 aluminum alloy plate: by mass percentage, Si 0.080%, Fe: 0.441%, Cu: 0.074%, Mn: 1.148%, Mg: 0.038%, Cr: 0.003%, Zn: 0.009%, Ti : 0.016%, other impurities ≤ 0.01%, all impurities ≤ 0.15%, the balance is Al;

[0045] A production method of 3003H14 aluminum alloy plate, using aluminum ingot as raw material, through melting and casting, sawing, face milling, ingot heating, hot rolling (hot rough rolling, hot finish rolling), cold rolling, cleaning and straightening and cross shearing ,Specific steps are as follows:

[0046] 1) Melting and casting: Aluminum ingots are used as raw materials to obtain ingots after melting and casting. The melting temperature is 735°C, the refining temperature is 725°C, and the casting temperature is 689°C;

[0047] 2) Heating the ingot obtained in step 1) after sawing and face milling, the heating temperature of the ingot is 505°C, and the holding time is 5h;

[0048] 3) Hot rolling: use four-high reversi...

Embodiment 3

[0054] A chemical composition of a 3003H14 aluminum alloy plate, by mass percentage, Si: 0.121%, Fe: 0.493%, Cu: 0.089%, Mn: 1.090%, Mg: 0.009%, Cr: 0.031%, Zn: 0.007%, Ti: 0.015%, other impurities ≤ 0.01%, all impurities ≤ 0.15%, the balance is Al;

[0055] A production method of 3003H14 aluminum alloy plate, using aluminum ingot as raw material, through melting and casting, sawing, face milling, ingot heating, hot rolling (hot rough rolling, hot finish rolling), cold rolling, cleaning and straightening and cross shearing ,Specific steps are as follows:

[0056] 1) Melting and casting: Aluminum ingots are used as raw materials to obtain ingots after melting and casting. The melting temperature is 740°C, the refining temperature is 735°C, and the casting temperature is 695°C;

[0057] 2) Heating the ingot obtained in step 1) after sawing and face milling, the heating temperature of the ingot is 510°C, and the holding time is 6h;

[0058] 3) Hot rolling: use four-high reversi...

PUM

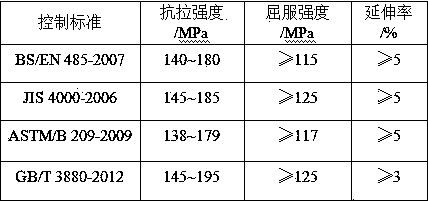

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com