Patents

Literature

33results about How to "Eliminate the annealing process" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

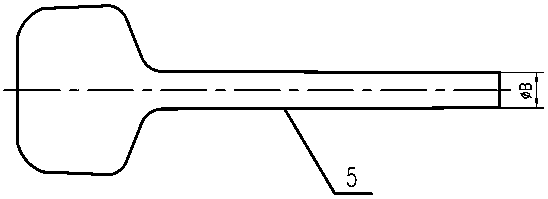

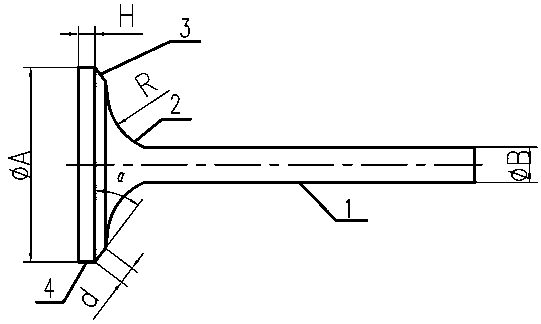

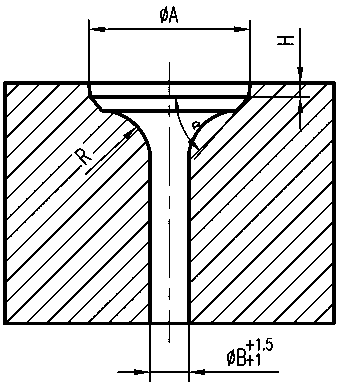

Laser strengthening process of piercing point

InactiveCN102732878AHigh surface hardnessImprove surface wear resistanceMetallic material coating processesPiercing pointHigh intensity

The invention relates to a laser strengthening process of a piercing point. The laser strengthening process comprises the following steps of: smelting a transition alloy layer on the surface of a substrate of the piercing point; smelting a high-strength alloy layer on the transition alloy layer by laser, wherein alloy powder used by the transition alloy layer is an nickel-based alloy; and the alloy powder used by the high-strength alloy layer is a cobalt-based alloy. In the process, the hardness of the transition alloy layer is lower than that of the high-strength alloy layer, has the transition effect on the high-hardness and high-abrasion-resistance high-strength alloy layer, and can better remit an overlaying stress, so that a residual overlaying stress does not cause great influences on tissues of a laser smelting layer even if the point is not pre-heated and not annealed, so that the phenomenon that the performance of the smelting layer is influenced by annealing can be effectively avoided and the surface hardness and the abrasion resistance of the piercing point are greatly improved; and meanwhile, the pre-heating and annealing processes are saved and the production efficiency is improved.

Owner:佛山市顺德区新特瓦钢型材有限公司

High intensity, corrosion resistant and high ductility steel for mooring chain and production process thereof

InactiveCN101182622AEliminate the annealing processAvoid problemsRoll mill control devicesMetal rolling arrangementsCorrosion resistantDuctility

The invention discloses a steel for mooring chains with high strength, corrosion resistance and high toughness and a production process thereof. Its chemical composition (wt%) is: C 0.18-0.25%, Si 0.10-0.35%, Mn 1.40-1.80%, Cr0.80-1.40%, Ni 0.60-1.20%, Mo 0.40-0.70%, Nb 0.02-0.06 %, Al0.02-0.06%, S≤0.010%, P≤0.020%, B≤0.005%, Cu≤0.20%, Sb≤0.010%, Sn≤0.03%, As≤0.04%, [O]≤0.0018% , [N]≤0.0060%, the rest is Fe. The present invention avoids the generation of martensitic structure through the composition optimization design, so that when the base metal does not adopt an annealing process, the material structure will not change and produce central cracks after a long time of storage, and the precious metal Ni is saved at the same time. The invention adopts RH / VD to degas and remove inclusions, which can significantly improve the cleanliness of steel, and reduce energy consumption and cost by adopting converter smelting.

Owner:JIANGSU SHAGANG GROUP HUAIGANG SPECIAL STEEL CO LTD

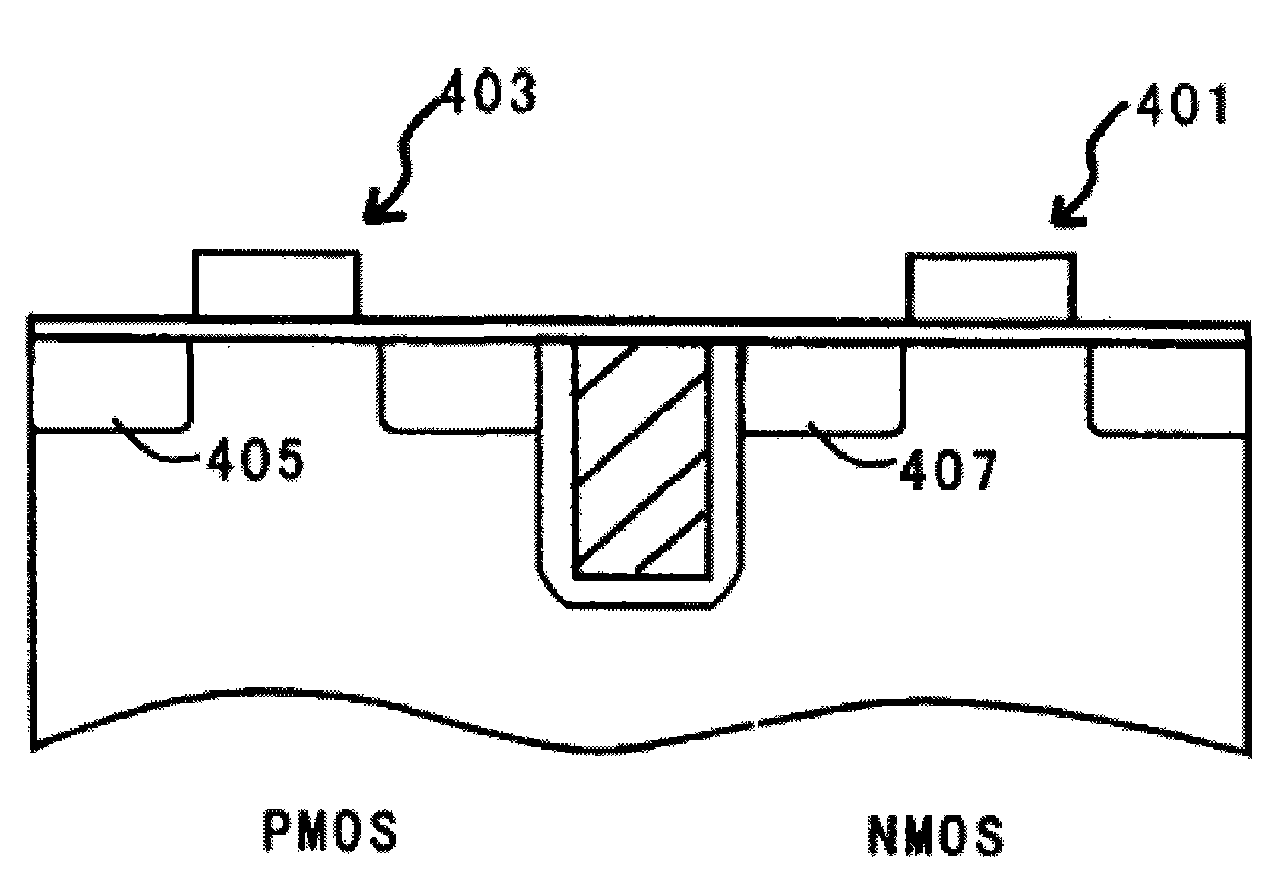

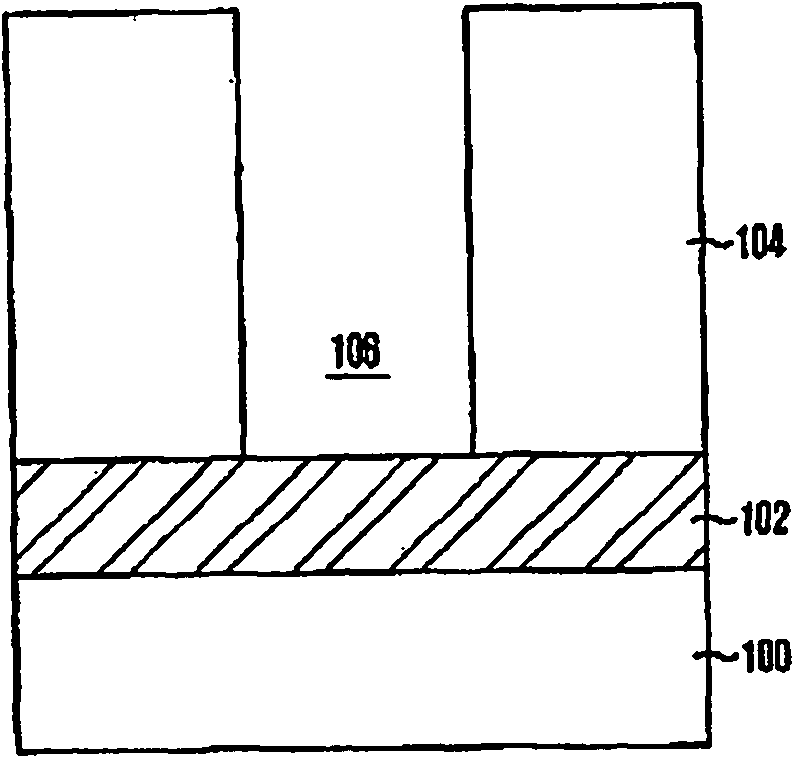

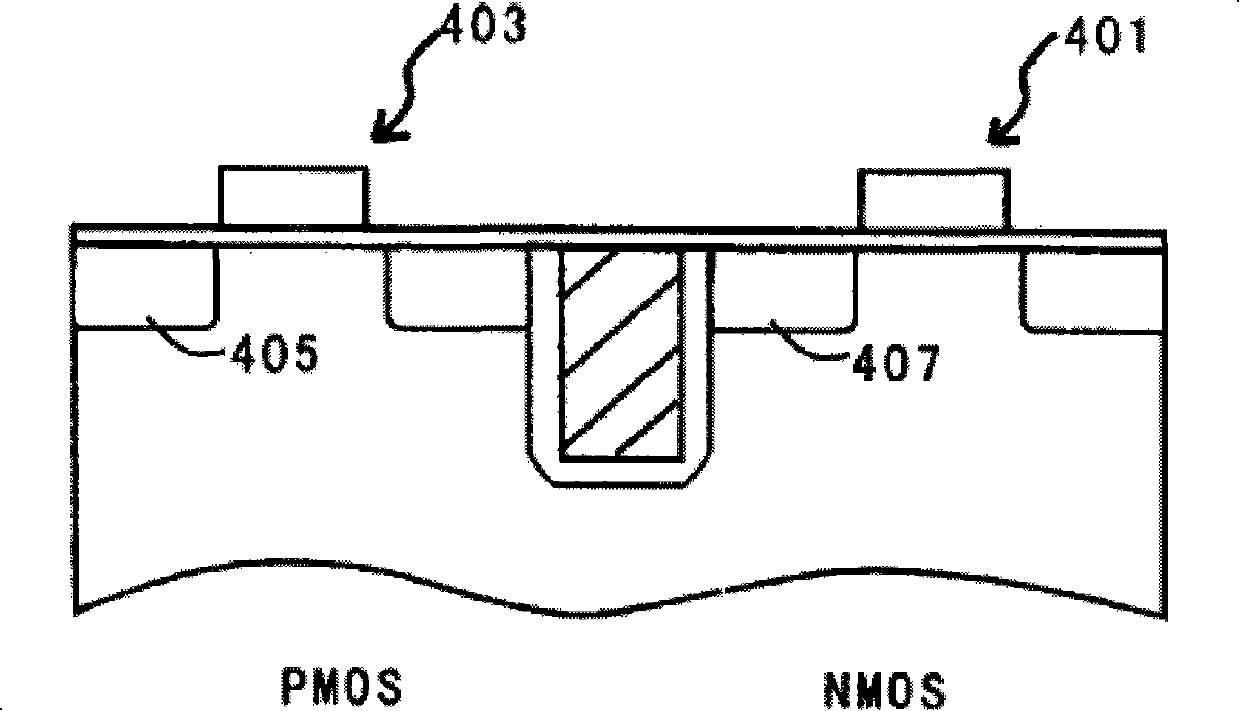

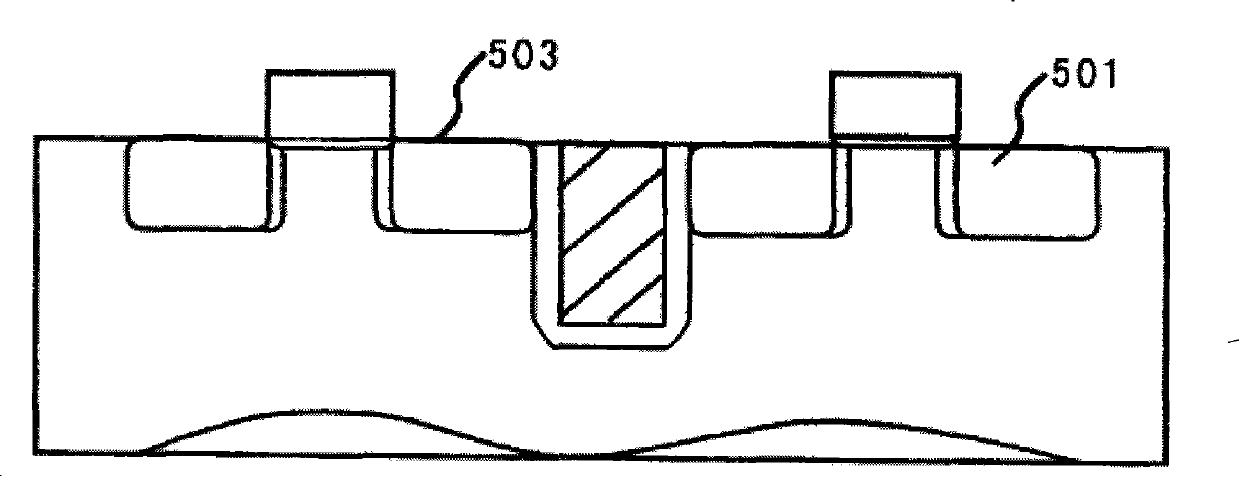

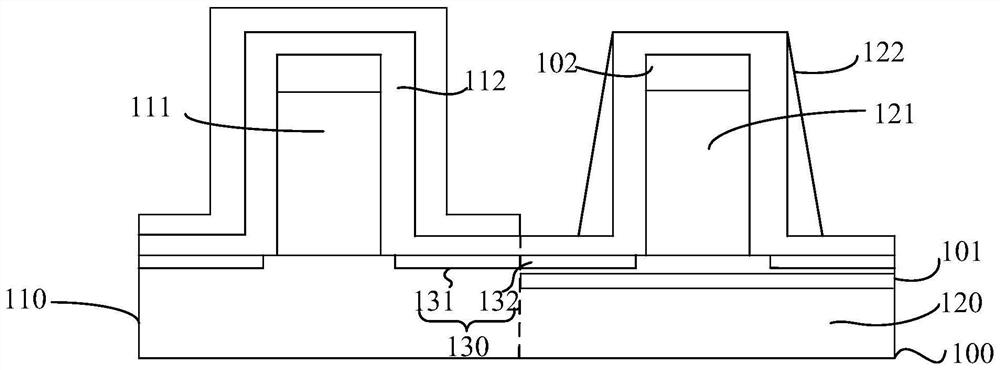

Stress NMOS device and manufacturing method of stress CMOS

ActiveCN101593701AImprove stabilityIncrease stressSemiconductor/solid-state device manufacturingDriving currentCMOS

A manufacturing method of a stress NMOS device comprises the followings: semiconductor substrates with grid structures are offered; a source electrode and a drain electrode are formed in the semiconductor substrates at two sides of the grid structures; wherein after the grid structures are formed and before the source electrode and the drain electrode are formed, or after the source electrode and the drain electrode are formed, the method further comprises the following steps: ions are implanted, and carbon impurities are doped in the semiconductor substrates at two side of the grid structures; solid phase epitaxy process is carried out to facilitate the carbon impurities react with silicon to form a strain silicon carbide layer. The invention also provides a manufacturing method of the stress CMOS device. Carbon in the strain silicon carbide layer in the stress MOS device formed by the invention has comparatively high content, the stress applied to an NMOS conducting channel by an epitaxial layer of a silicon carbide material is greatly increased; the mobility of carriers can be effectively improved, thus enlarging the drive current and improving the performance of the NMOS device.

Owner:SEMICONDUCTOR MANUFACTURING INTERNATIONAL (BEIJING) CORP

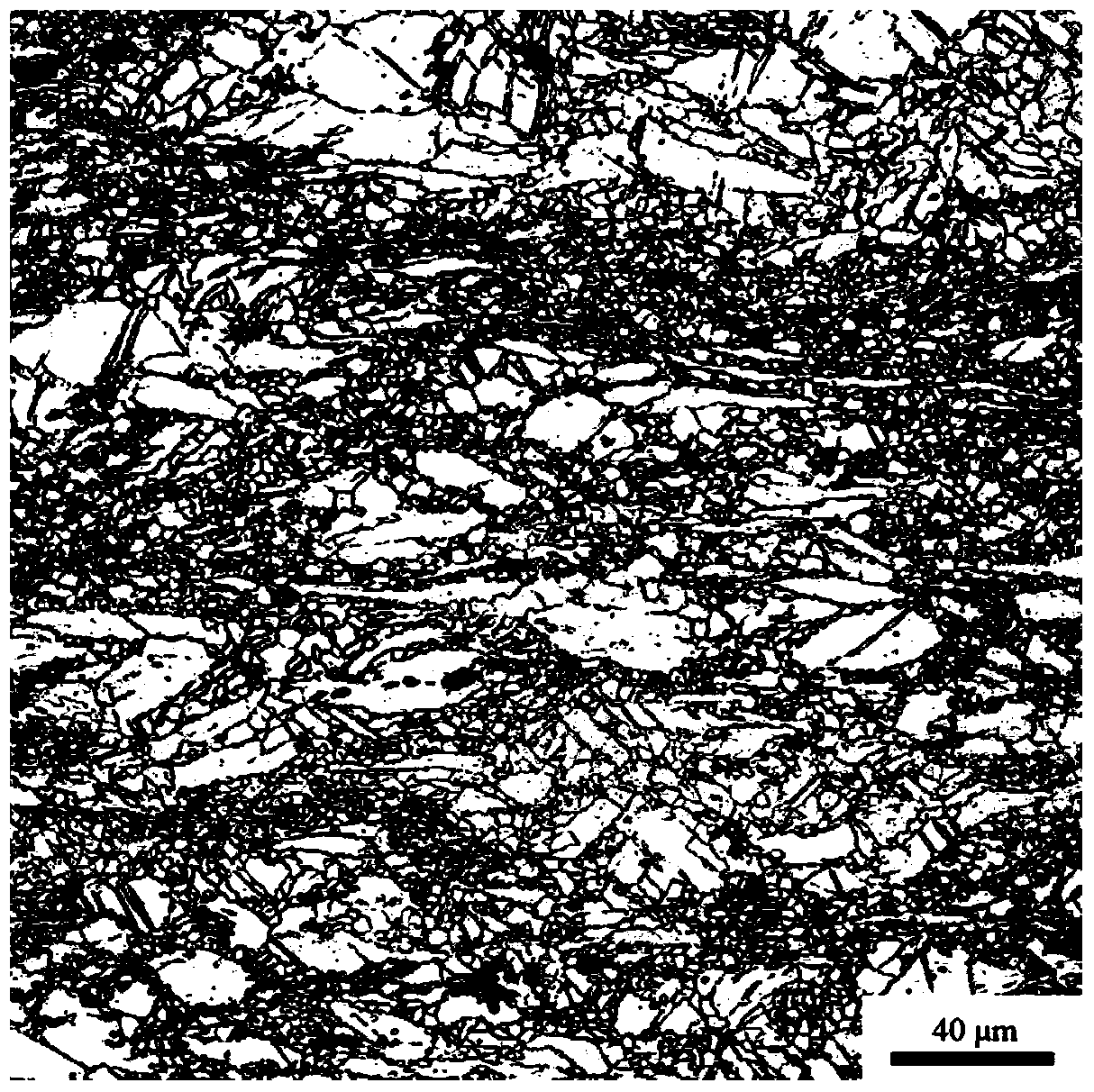

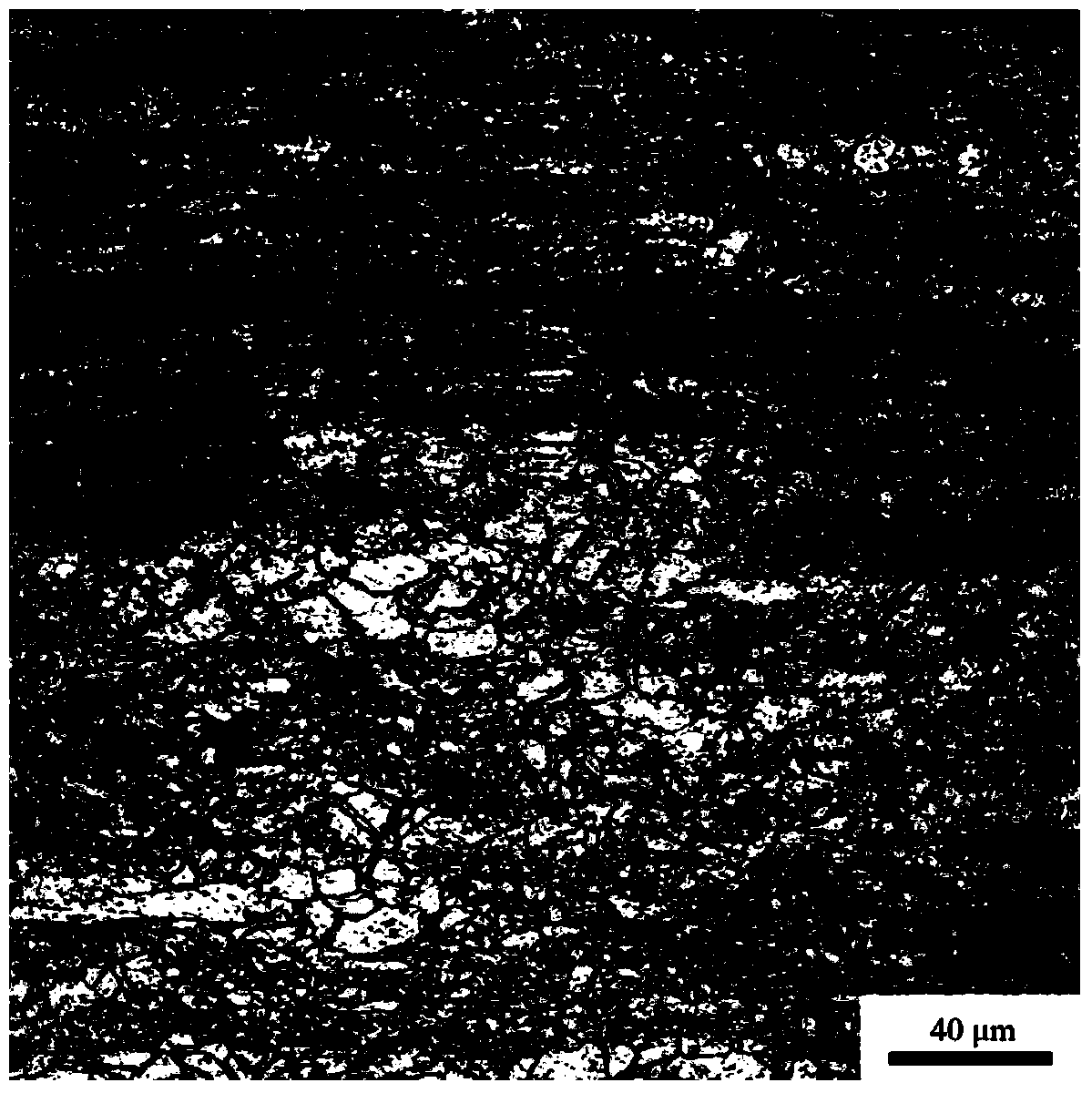

Method for rolling high-ductility and high-scalability Mg-Al series magnesium alloy plates

InactiveCN104259201AEnhanced ability to recover and recrystallizeImprove plasticityTemperature control deviceTension/compression control deviceDynamic recrystallizationSingle pass

The invention relates to a magnesium alloy processing method, in particular to a method for rolling high-ductility and high-scalability Mg-Al series magnesium alloy plates. The method comprises the steps of milling, heating and heat preservation of a plate, heating and heat preservation of a roller, rolling and cooling, wherein the rolling speed is 10-100 m / min; the rolling reduction of each time of rolling is 45%-80%. As the high-speed single-pass big-dependent-variable rolling is adopted for inducing obvious dynamic recrystallization, fully fine equiaxed grains are generated, and accordingly, the magnesium alloy plates of which the ductility and the scalability are greatly improved are acquired. Besides, as the annealing process is omitted, the manufacturing cost is greatly lowered, and the method is more suitable for large-scale industrial production.

Owner:CHONGQING UNIV

Production method of alloy steel roller

InactiveCN103614667AHigh temperature resistantSelf-lubricatingRollsProcess efficiency improvementIntermediate frequencyTemperature resistance

The invention relates to a production method of an alloy steel roller, which comprises the following steps: 1) smelting; 2) furnace pretreatment; 3) casting; 4) rough machining; 5) quenching; 6) tempering; 7) finish machining. Compared with the prior art, the method provided by the invention has the advantages that (1) ferrous sulfide is used as an alterant, the produced alloy steel roller has the advantages of high temperature resistance, self-lubrication, wear resistance and the like, and the roller does not need lubrication or needs a little lubrication in application so that the working strength of workers is reduced; (2) without rare metal Co, the production cost is lowered; (3) the method adopts an intermediate frequency furnace for smelting, a horizontal centrifuge for pouring and a common high-temperature resistance furnace for heat treatment, so that the equipment investment is low; moreover, since an annealing process is saved in processing, the production process is simple and reasonable, and the production efficiency is greatly improved.

Owner:湖州市银鑫轧辊有限公司

High-sulfur alloy steel roll and production method

InactiveCN102628147AHigh temperature resistantSelf-lubricatingRollsElectric furnaceChemical compositionIntermediate frequency

The invention relates to a high-sulfur alloy steel roll and a production method. The high-sulfur alloy steel roll comprises the following chemical components by weight percent: 0.4%-1.0% of C, 0.5%-1% of Si, 0.5%-1% of Mn, 1.5%-10% of S, less than 0.05% of P, 4%-6% of Cr, 0.05%-1.5% of V, 0.1%-0.4% of Mo, less than 2% of W, 0.05%-0.1% of Ti, 0.005%-0.1% of Ba, less than 0.05% of Re, and the balance of Fe. The acknowledged rule that sulfur cannot exceed 0.03% is broken by the high-sulfur alloy steel roll; harmful elements are converted into beneficial elements; the produced high-sulfur alloy steel roll has the advantages of high-temperature resistance, self-lubricating property, abrasion resistance, and the like; no lubrication or less lubrication is required by the roll during application process, so that the working strength of workers is relieved; the rare metal Co is not contained, so that the production cost is lowered; an intermediate frequency furnace is used for melting; a horizontal centrifuge is used for pouring; a common high-temperature resistance furnace is used for performing thermal treatment; the equipment investment is less; the processing technology is free from annealing process; the production technology is simple and reasonable; and the production efficiency is greatly increased.

Owner:常熟市轧辊厂限公司

Piercing plug laser strengthening process dispensing with preheating before laser cladding

ActiveCN103572280ARelieve surfacing stressImprove hardness and wear resistanceMetallic material coating processesHigh intensityHardness

The invention relates to a laser strengthening process of a piercing plug. The laser strengthening process is characterized by firstly carrying out laser cladding on a transition alloy layer on the surface of a piercing plug matrix and then carrying out laser cladding on the high-strength alloy layer on the transition alloy layer, wherein the alloy powder adopted by the transition alloy layer is the nickel base alloy; the alloy powder adopted by the high-strength alloy layer is the cobalt base alloy. The laser strengthening process has the advantages that the transition alloy layer in the process has lower hardness than the high-strength alloy layer, plays a role in transition for the high-strength alloy layer with high hardness and high wear resistance and can well relieve the surfacing stress, so that even if the plug is not preheated or annealed, the residual surfacing stress can not have great impacts on the tissues of a laser cladding layer, thus effectively avoiding impacting the properties of the cladding layer by annealing, substantially improving the surface hardness and wear resistance of the piercing plug, simultaneously omitting the processes of preheating and annealing and also improving the production efficiency.

Owner:JIANGSU ZHONGOU FERTILIZER

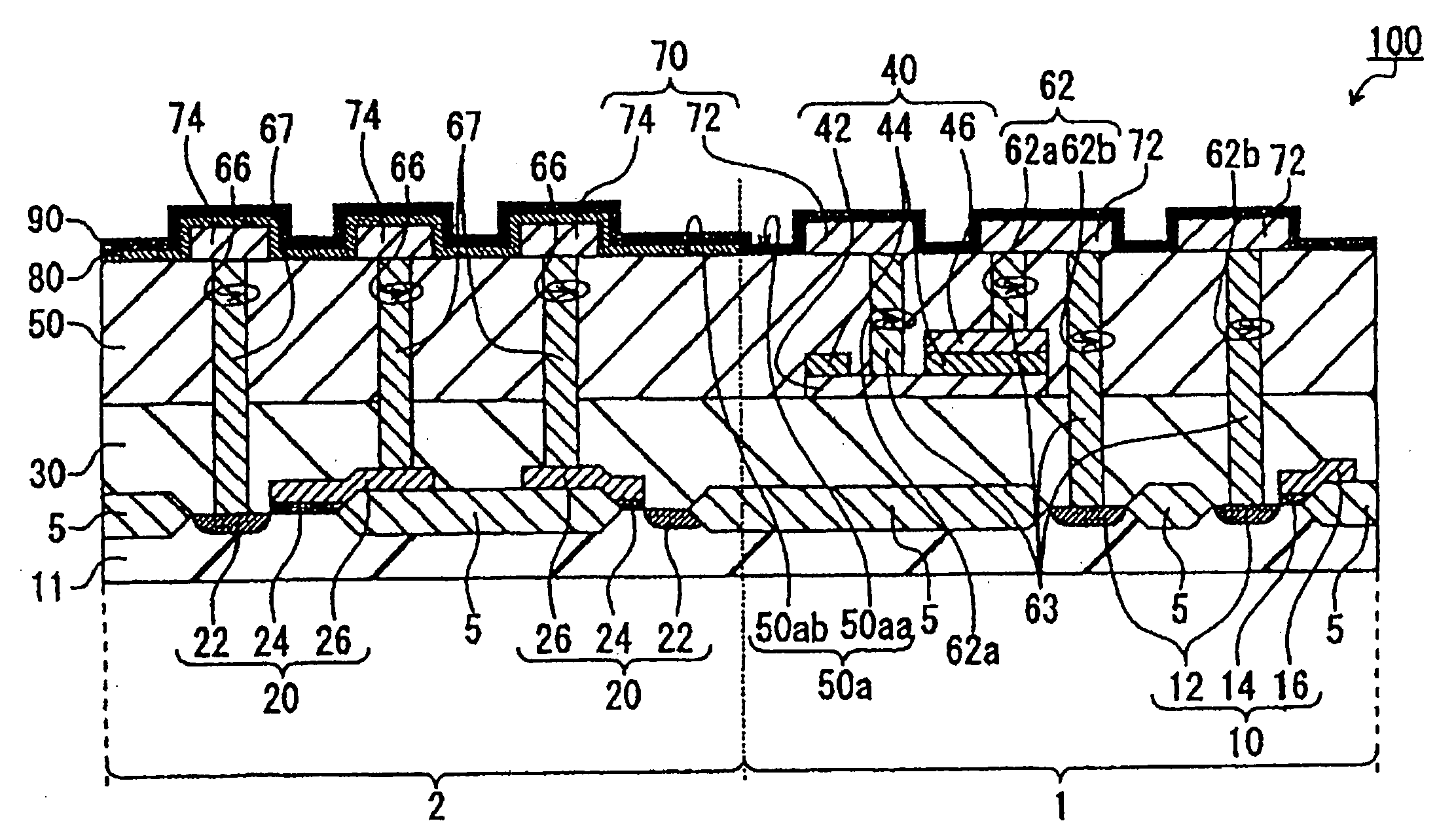

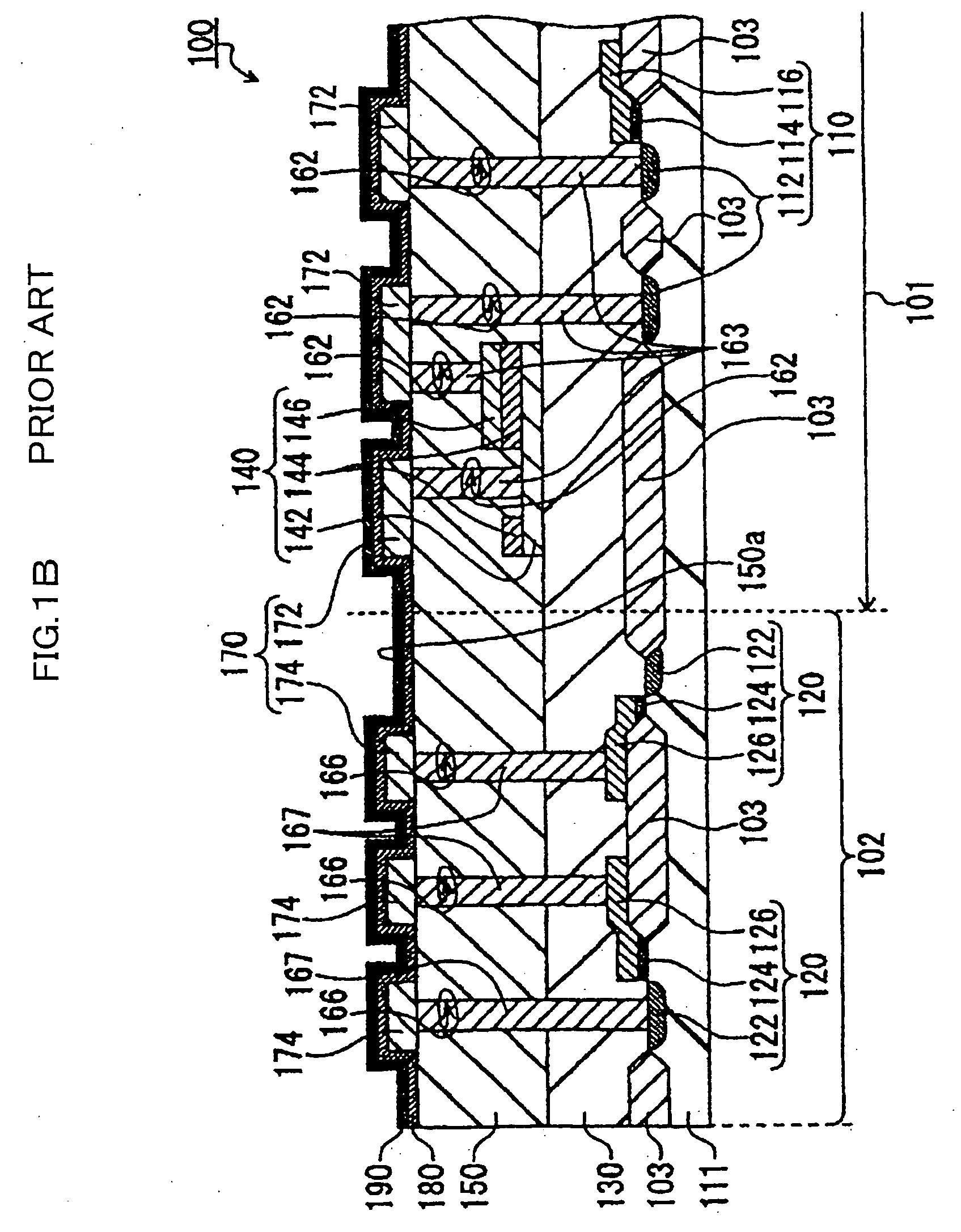

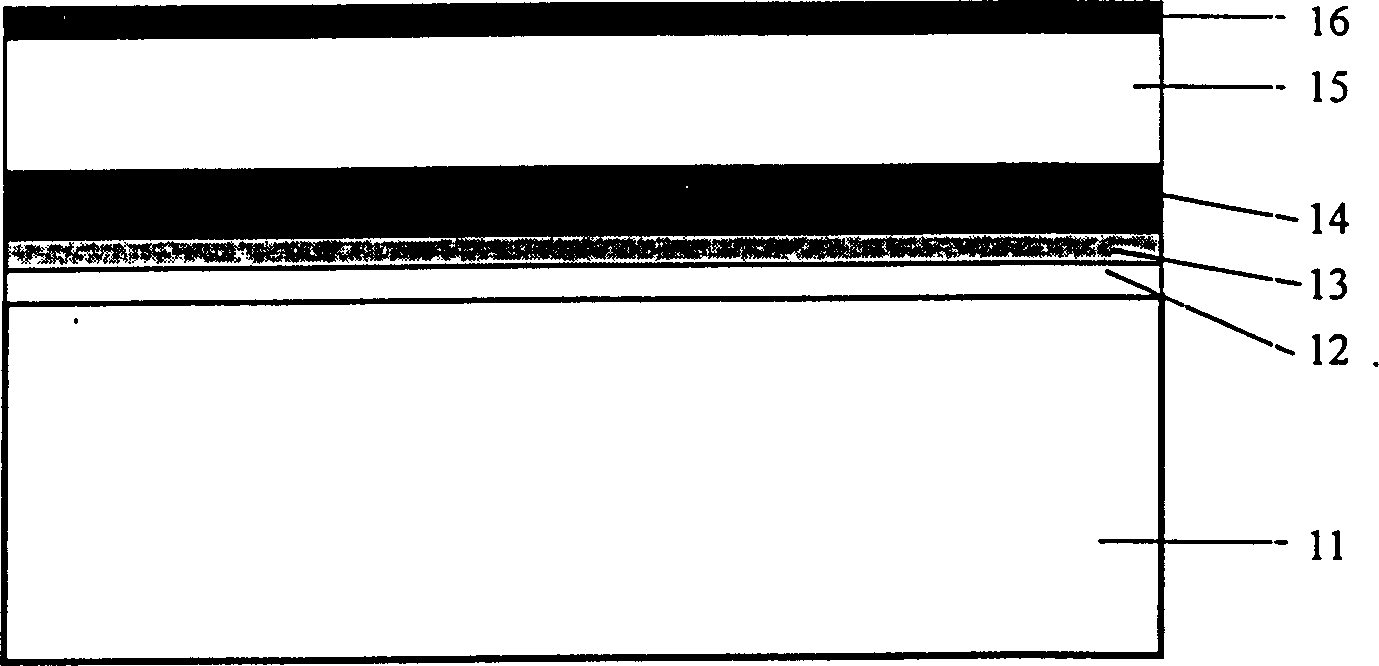

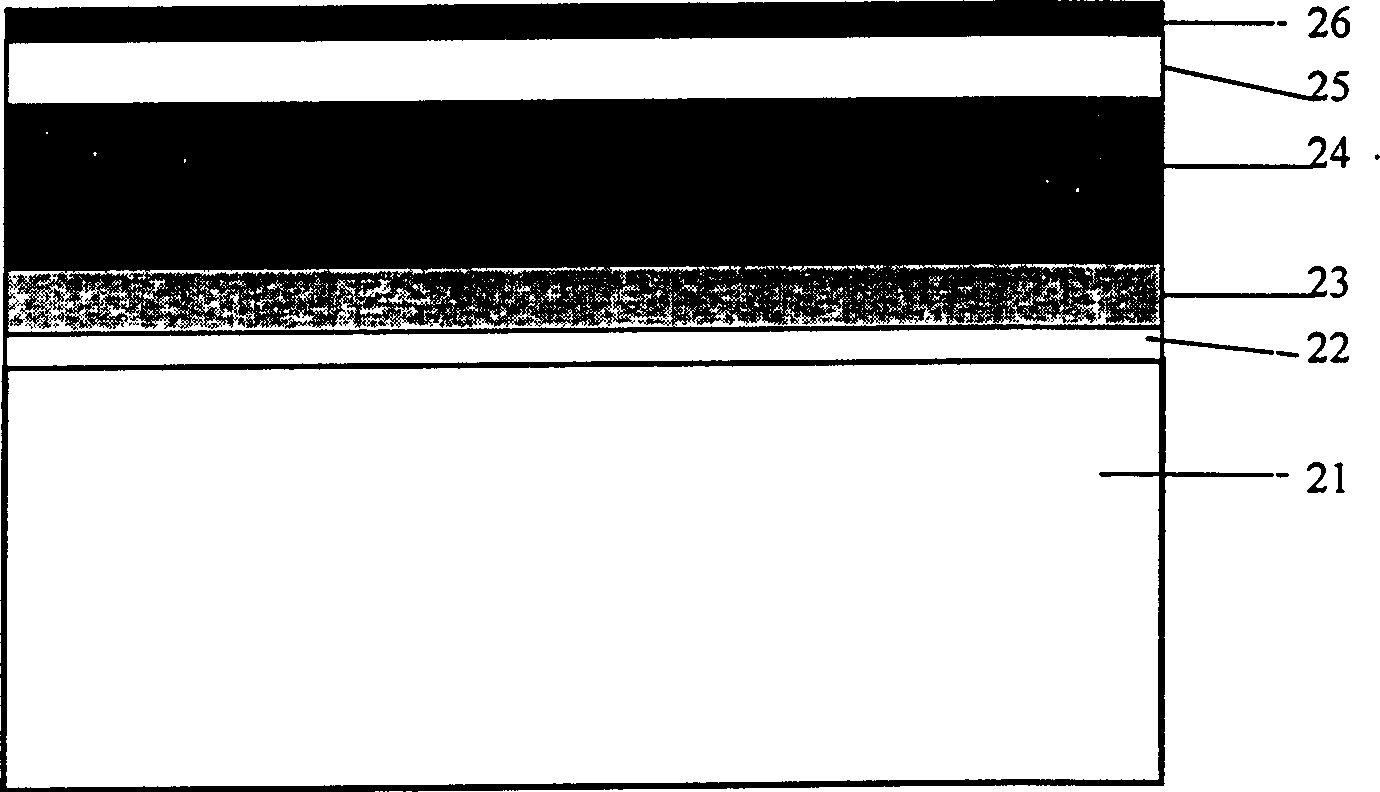

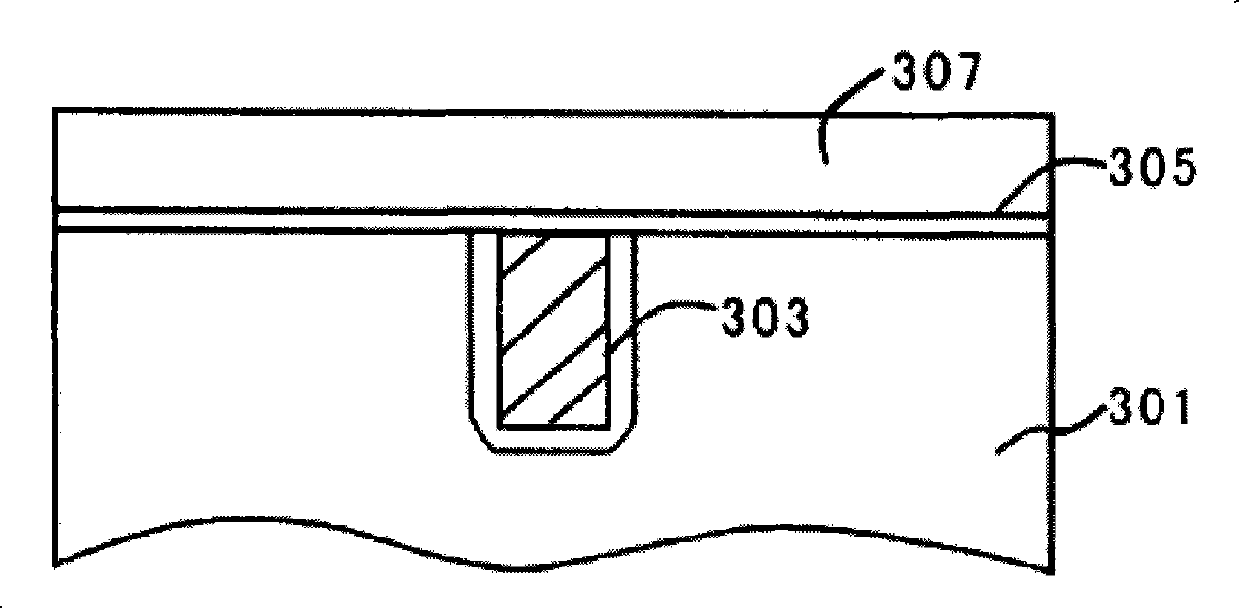

Hybrid memory device and method for manufacturing the same

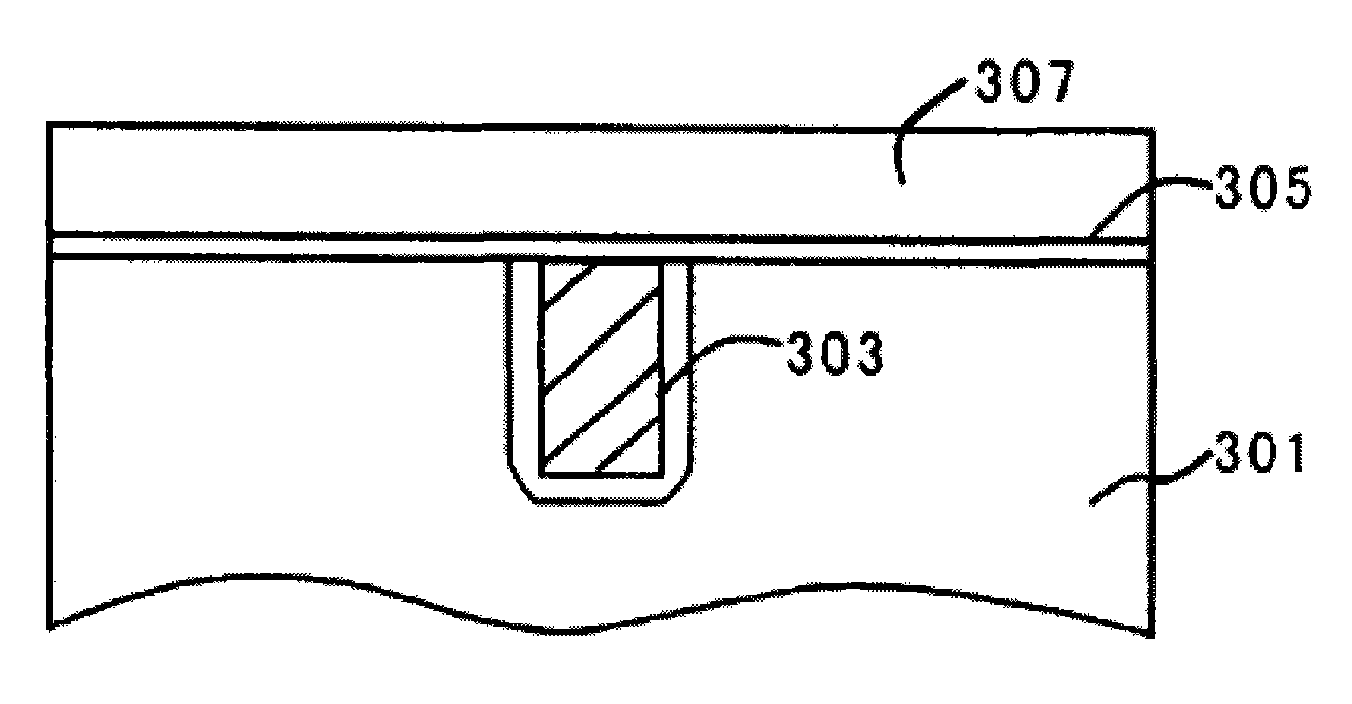

InactiveUS20060065917A1High performance ferroelectric memory cell arrayDeterioration of characteristicSolid-state devicesSemiconductor/solid-state device manufacturingEngineeringStorage cell

A hybrid memory device includes a plurality of regions including a memory cell array region upon which are formed a plurality of memory cells and a logic circuit region upon which is formed a logic circuit device, and is provided with a liner oxide layer formed on a region covering the logic circuit region except the memory cell array region and a cover layer formed on the liner oxide layer while extending to the memory cell array region.

Owner:LAPIS SEMICON CO LTD

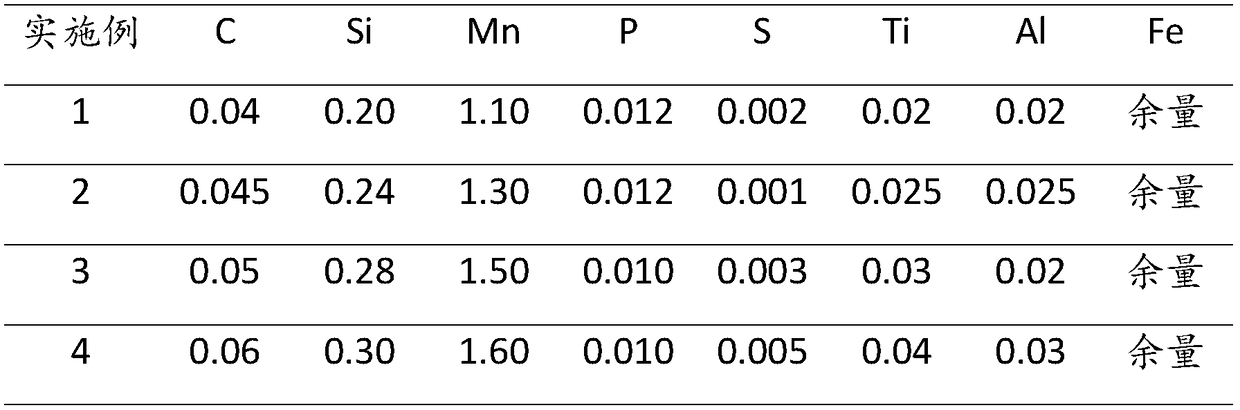

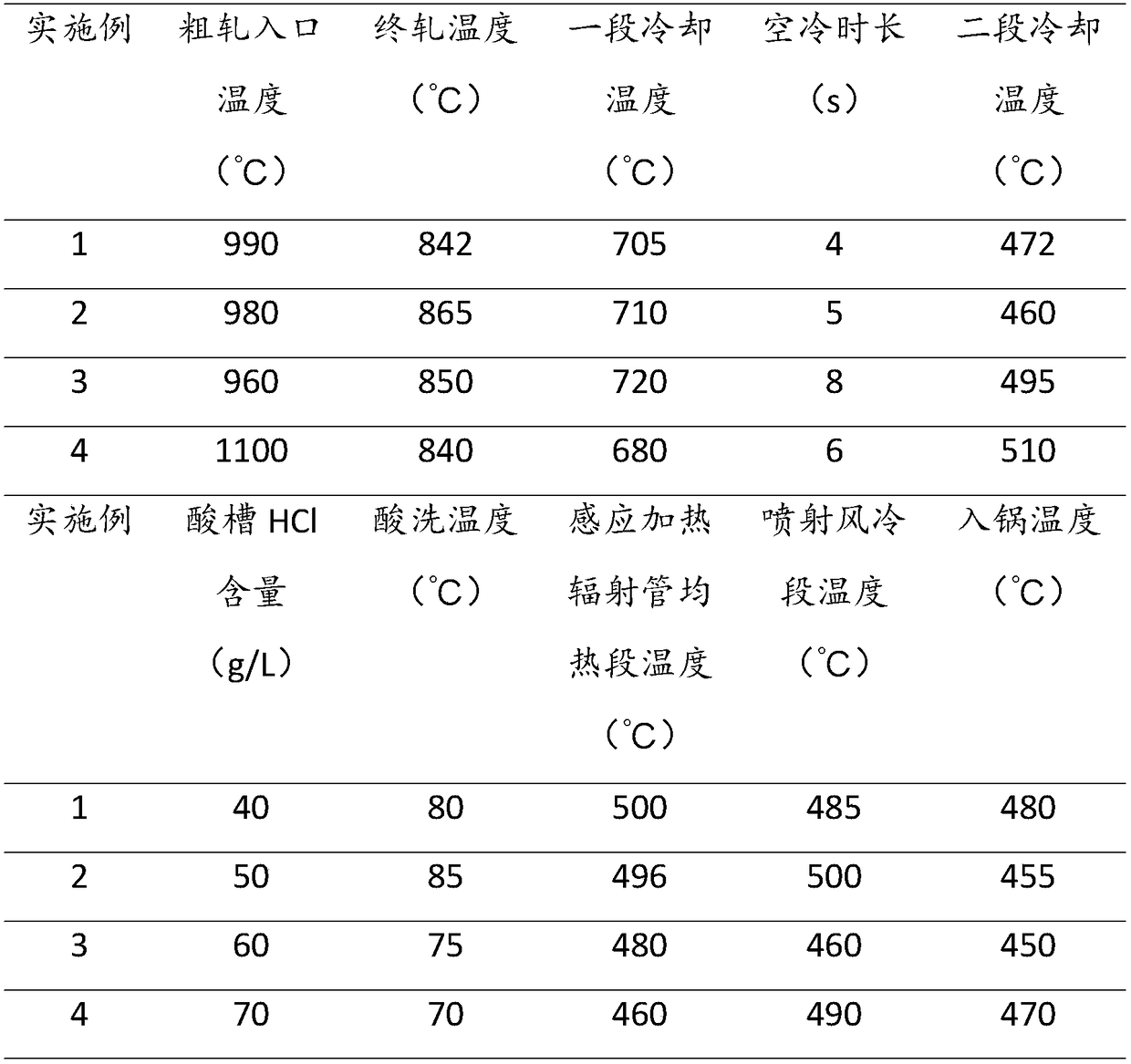

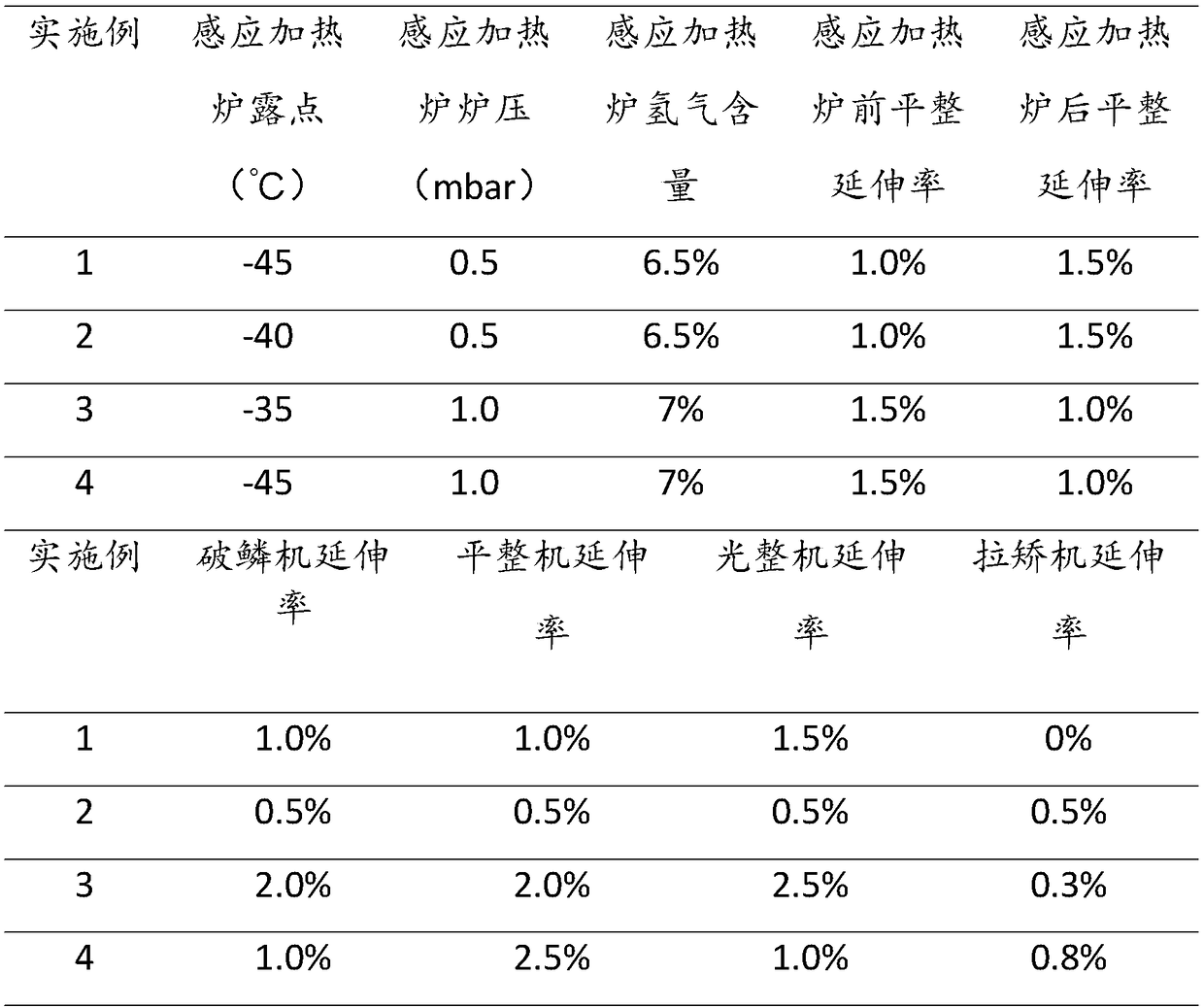

Method for producing highly-reaming hot-dip galvanized sheet with tensile strength of 540 MPa

ActiveCN109055867ASolve the impact of safe and stable operationHigh elongationHot-dipping/immersion processesSteelmakingProduction line

The invention discloses a method for producing a highly-reaming hot-dip galvanized sheet with the tensile strength of 540 MPa and belongs to the technical field of hot-dip galvanized sheets. The technical solution is as follows: (1) preparing molten iron; (2) pretreating the molten iron, and performing converter steelmaking and LF furnace refining; (3) after treatment by the LF furnace, performingtreatment on an ESP production line, so that a hot-rolled strip steel with the thickness of 1.0 4.0 mm is prepared; (4) cooling the hot-rolled strip steel obtained in step (3), reeling the cooled hot-rolled strip steel and putting the same into a warehouse, so that a hot-rolled raw material reel is prepared; and step (5), after the prepared hot-rolled raw material reel is inspected, transferringthe hot-rolled raw material reel to a PGL acid-plating continuous production line for hot galvanizing, so that the hot-dip galvanized sheet is prepared. The tensile strength of the hot-dip galvanizedsheet produced through the method disclosed by the invention is greater than 540 MPa; and compared with a traditional hot-dip galvanized sheet production method, the method disclosed by the inventionhas the advantages that the process procedure is shortened and the energy saving and cost reduction are achieved.

Owner:RIZHAO STEEL HLDG GROUP

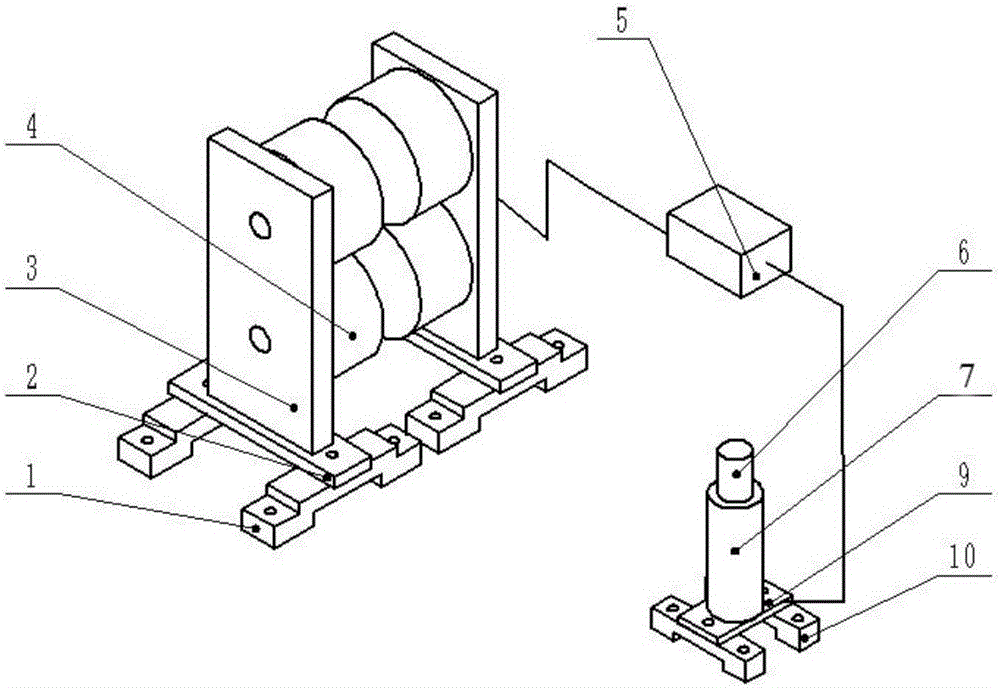

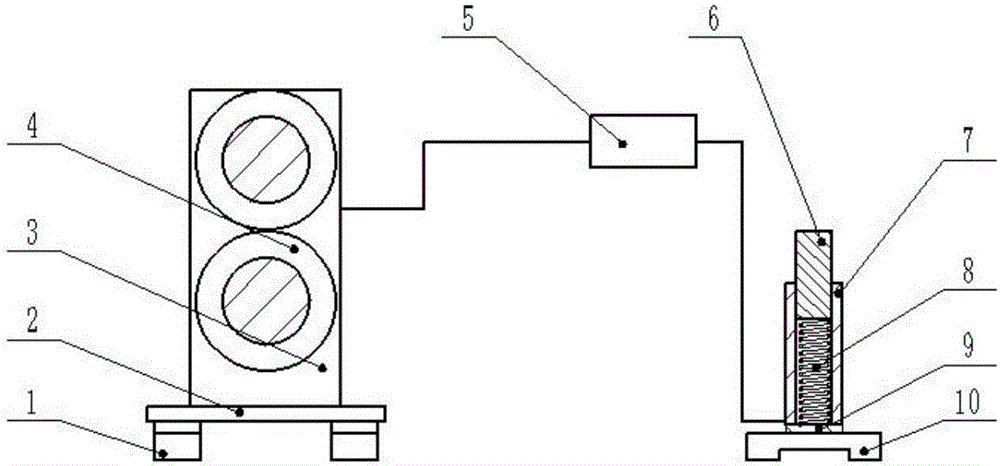

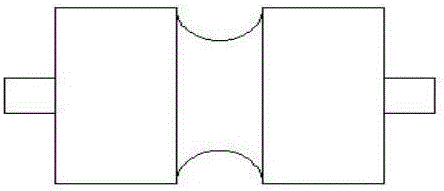

Pulse current auxiliary inner grooved copper tube forming device

The invention discloses a pulse current auxiliary inner grooved copper tube forming device, which comprises a power, a tube blank contact device and a formed tube contact device. The tube blank contact device comprises a bottom plate, an insulating plate, support frames, rolling bodies, wherein two rolling bodies in up and down arrangement form a group and are fixed between the two support frames; a formed tube contact device comprises a tightening spring, a sleeve and a graphite block; the tube blank contact device and a copper tube before reducing processing are in rolling contact; a positive electrode of the power supply is connected with the tube blank contact device; the formed tube contact device contacts with the copper tube after spinning of internal thread and sizing process; and the negative electrode of the power supply is connected with the formed tube contact device. During operation, the power supply continuously outputs pulse current to form a closed loop with the tube blank contact device, the copper tube and the formed tube contact device. The invention uses the electro plastic effect of metal in the inner grooved copper tube machining process to improve the elongation of the copper tube, so that the metal has good fluidity in spinning forming to obtain an ideal tooth shape; and the device reduces deformation resistance, is easy for drawing, and omits an annealing process.

Owner:JIANGSU RUNFU MECHANICAL ROLL MFG

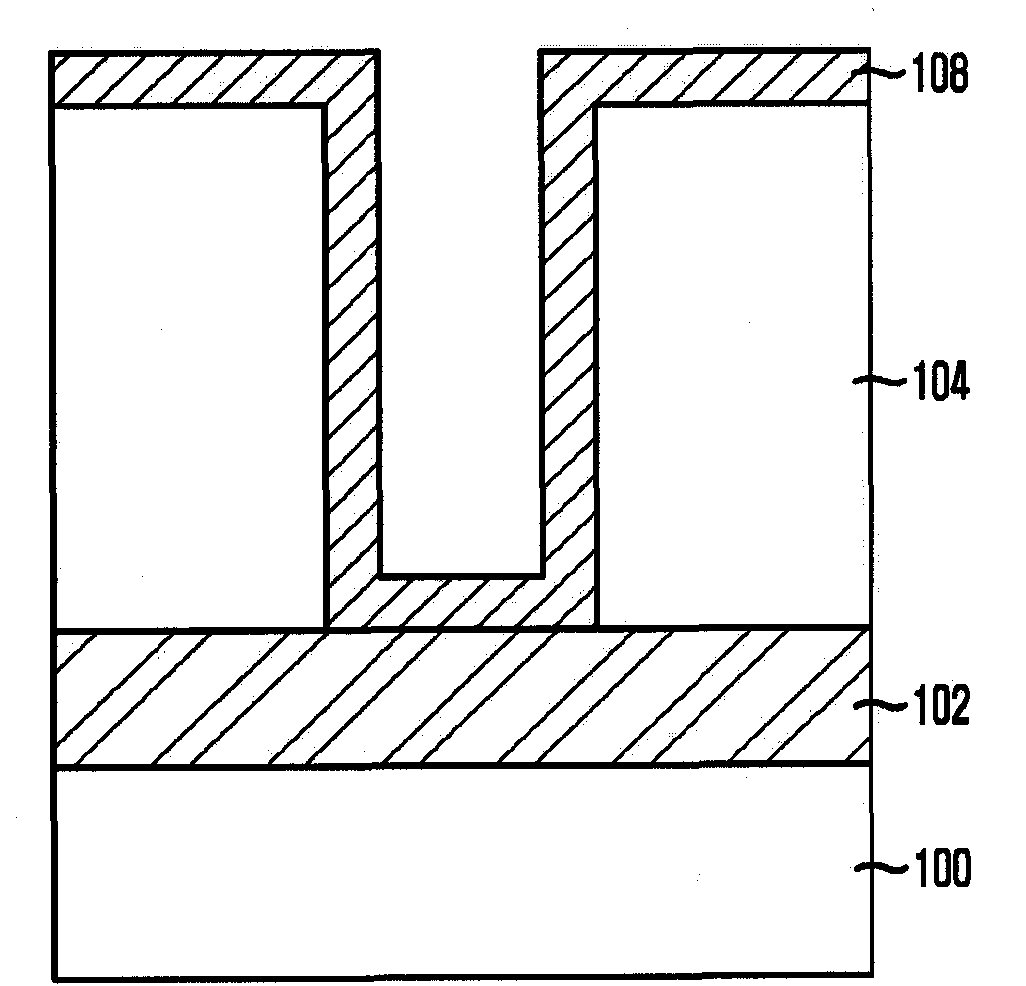

Method for manufacturing cmos image sensor

InactiveCN102099914AImprove dark featuresShorten the timeSolid-state devicesSemiconductor/solid-state device manufacturingCMOSBiomedical engineering

An object of the present invention is to provide a method for manufacturing a CMOS image sensor, capable of preventing hillock defects caused by a wire lifting phenomenon in a CMOS image sensor. To this end, the present invention provides a method for manufacturing a CMOS image sensor, including the steps of: preparing a substrate on which a first metal wire is formed; forming an interlayer insulating layer on the first metal wire; etching the interlayer insulating layer to form a contact hole for exposing a part of the first metal wire; forming a buffer layer on the interlayer insulating layer along an inner surface of the contact hole; performing a heat treatment process; etching the buffer layer to form a spacer on an inner wall of the contact hole; forming a barrier metal layer along an upper surface of the interlayer insulating layer including the spacer; forming a contact plug on the barrier metal layer such that the contact hole is buried; and forming a second metal wire on theinterlayer insulating layer such that the second metal wire is connected to the contact plug.

Owner:INTELLECTUAL VENTURES II

Piercing plug laser strengthening process dispensing with annealing after laser cladding

ActiveCN103572281AHigh surface hardnessImprove surface wear resistanceMetallic material coating processesHigh intensityHigh wear resistance

The invention relates to a laser strengthening process of a piercing plug. The laser strengthening process is characterized by firstly carrying out laser cladding on a transition alloy layer on the surface of a piercing plug matrix and then carrying out laser cladding on the high-strength alloy layer on the transition alloy layer, wherein the alloy powder adopted by the transition alloy layer is the nickel base alloy; the alloy powder adopted by the high-strength alloy layer is the cobalt base alloy. The laser strengthening process has the advantages that the transition alloy layer in the process has lower hardness than the high-strength alloy layer, plays a role in transition for the high-strength alloy layer with high hardness and high wear resistance and can well relieve the surfacing stress, so that even if the plug is not preheated or annealed, the residual surfacing stress can not have great impacts on the tissues of a laser cladding layer, thus effectively avoiding impacting the properties of the cladding layer by annealing, substantially improving the surface hardness and wear resistance of the piercing plug, simultaneously omitting the processes of preheating and annealing and also improving the production efficiency.

Owner:邳州市润宏实业有限公司

Laser strengthening process of piercing plug

ActiveCN103572283AHigh surface hardnessImprove surface wear resistanceMetallic material coating processesHardnessHigh intensity

The invention relates to a laser strengthening process of a piercing plug. The laser strengthening process is characterized by firstly carrying out laser cladding on a transition alloy layer on the surface of a piercing plug matrix and then carrying out laser cladding on a high-strength alloy layer on the transition alloy layer, wherein the alloy powder adopted by the transition alloy layer is the nickel base alloy; the alloy powder adopted by the high-strength alloy layer is the cobalt base alloy. The laser strengthening process has the advantages that the transition alloy layer in the process has lower hardness than the high-strength alloy layer, plays a role in transition for the high-strength alloy layer with high hardness and high wear resistance and can well relieve the surfacing stress, so that even if the plug is not preheated or annealed, the residual surfacing stress can not have great impacts on the tissues of a laser cladding layer, thus effectively avoiding impacting the properties of the cladding layer by annealing, substantially improving the surface hardness and wear resistance of the piercing plug, simultaneously omitting the processes of preheating and annealing and also improving the production efficiency.

Owner:邳州市润宏实业有限公司

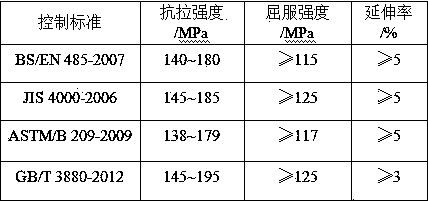

3003H14 aluminum alloy sheet and production method thereof

The invention provides a 3003H14 aluminum alloy sheet and a production method thereof. The 3003H14 aluminum alloy sheet comprises the following components in percentage by mass: less than or equal to0.20% of Si, 0.40-0.50% of Fe, less than or equal to 0.15% of Cu, 1.05-1.20% of Mn, less than or equal to 0.05% of Mg, less than or equal to 0.05% of Cr, less than or equal to 0.10% of Zn, 0.01-0.05%of Ti, less than or equal to 0.05% of other single impurity, less than or equal to 0.15% of all impurities in all and the balance being Al. The production method comprises the following steps: carrying out fusion casting, saw cutting, face-milling, ingot casting heating, hot rolling, cold rolling, cleaning, pulling straightening and transverse shear in sequence. The production method has the beneficial effects that the production method can ensure the performances of the product and shorten the production process; the mechanical properties are controlled by hot rolling plus one-pass cold rolling; and the 3003H14 aluminum alloy sheet product with the thickness of 2.0-4.0mm is produced, and the cost is saved.

Owner:CHINALCO RUIMIN

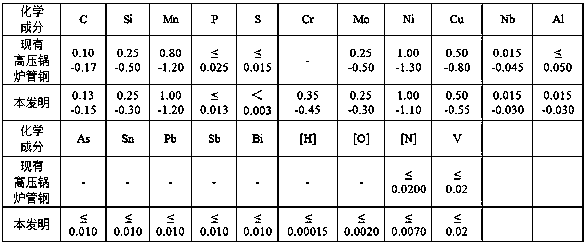

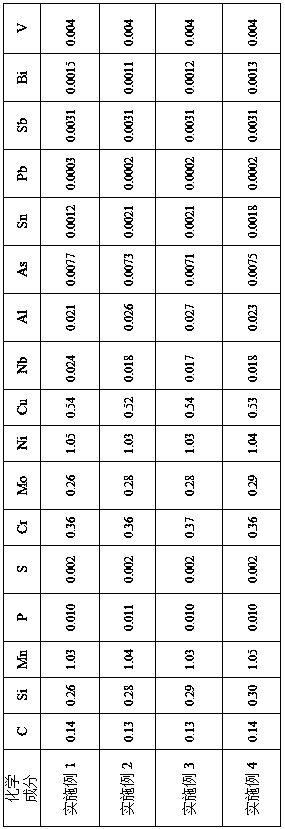

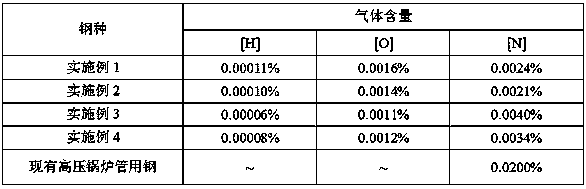

Heat-resistant steel for corrosion-resistant high-pressure boiler pipe and production method thereof

ActiveCN109930064AReduce hardnessEliminate internal stressMelt-holding vesselsManufacturing convertersComposite effectHigh pressure

The invention discloses heat-resistant steel for a corrosion-resistant high-pressure boiler pipe and a production method thereof. The heat-resistant steel comprises the following chemical components of, by weight, 0.13%-0.15% of C, 0.25%-0.30% of Si, 1.00%-1.20% of Mn, 0.35%-0.45% of Cr, 0.25%-0.30% of Mo, 1.00%-1.10% of Ni, 0.50%-0.55% of Cu, 0.015%-0.030% of Nb, 0.015%-0.030% of Al, less than orequal to 0.013% of P, less than 0.003% of S, less than or equal to 0.010% of As, less than or equal to 0.010% of Sn, less than or equal to 0.010% of Pb, less than or equal to 0.010% of Sb, less thanor equal to 0.010% of Bi, less than or equal to 0.035% of As+Sn+Sb+Pb+Bi, less than or equal to 0.02% of V, less than or equal to 0.00015% of [H], less than or equal to 0.0020% of [O], less than or equal to 0.0070% of [N] and the balance Fe. According to the components, the heat-resistant steel for the corrosion-resistant high-pressure boiler pipe and the production method thereof have the advantages that a small amount of Cr elements are added, the Cu-Cr composite effect is utilized, and the high-temperature strength, the creep resistance and the H2S corrosion resistance of the high-pressureboiler pipe are improved.

Owner:JIANGSU LIHUAI IRON AND STEEL CO LTD +1

Inorganic electroluminescent display and its manufacturing method

InactiveCN1808732AImprove pressure resistanceReduce the impactSemiconductor devicesHigh volume manufacturingDielectric layer

This invention discloses one inorganic electroluminescence display and its process method and relates to the relative technique field suitable for alternating driving, wherein, the display upper dielectric layer is thicker than the down one; the dielectric layer touching to the light layer adopts high dielectric parameter materials; the light layer is mixed with light semiconductor layer; the said upper dielectric layer is formed by multiple compound medium film. The invention method processes some parts by annealing procedure to omit one light layer annealing process.

Owner:INESA ELECTRON

Machining method of diesel engine valve blank

ActiveCN110814662AEliminate the annealing processEliminate the rough turning process before valve surface strengtheningSolution treatmentDieseling

The invention discloses a manufacturing method of a diesel engine valve blank. The manufacturing method comprises the following steps of S1, hot upsetting forming, specifically, conducting upsetting on a bar on an electric upset forging machine to form a rough blank and conducting forging and pressing in a die to form a forging blank; S2, heat treatment, specifically, feeding the forging blank into a high-temperature furnace to be subjected to solution treatment immediately after completion of forging and pressing, conducting water cooling to the indoor temperature, conducting heat preservation and aging treatment at 750-780 DEG C for 10-12 h and then discharging the forging blank from the furnace; and S3, deformation strengthening, specifically, feeding the forging blank into a deformation strengthening die within 3-5 s after aging treatment and furnace discharge, conducting forging and pressing at pressure of 6500-17000 KN for 1-3 times, conducting oil cooling on the forging blank tothe indoor temperature to obtain the diesel engine valve blank. Through the manufacturing method, the requirement for the performance of the valve blank can be met, the service life of the valve blank can be prolonged, the production procedures can be reduced, the consumption and production cost of a raw material can be reduced, and the production cycle can be shortened.

Owner:CHONGQING YUEJIN MACHINERY

Laser strengthening process of perforated plug

ActiveCN103572283BHigh surface hardnessImprove surface wear resistanceMetallic material coating processesPiercing pointHigh intensity

The invention relates to a laser strengthening process of a piercing point. The laser strengthening process comprises the following steps of: smelting a transition alloy layer on the surface of a substrate of the piercing point; smelting a high-strength alloy layer on the transition alloy layer by laser, wherein alloy powder used by the transition alloy layer is an nickel-based alloy; and the alloy powder used by the high-strength alloy layer is a cobalt-based alloy. In the process, the hardness of the transition alloy layer is lower than that of the high-strength alloy layer, has the transition effect on the high-hardness and high-abrasion-resistance high-strength alloy layer, and can better remit an overlaying stress, so that a residual overlaying stress does not cause great influences on tissues of a laser smelting layer even if the point is not pre-heated and not annealed, so that the phenomenon that the performance of the smelting layer is influenced by annealing can be effectively avoided and the surface hardness and the abrasion resistance of the piercing point are greatly improved; and meanwhile, the pre-heating and annealing processes are saved and the production efficiency is improved.

Owner:PIZHOU RUNHONG IND CO LTD

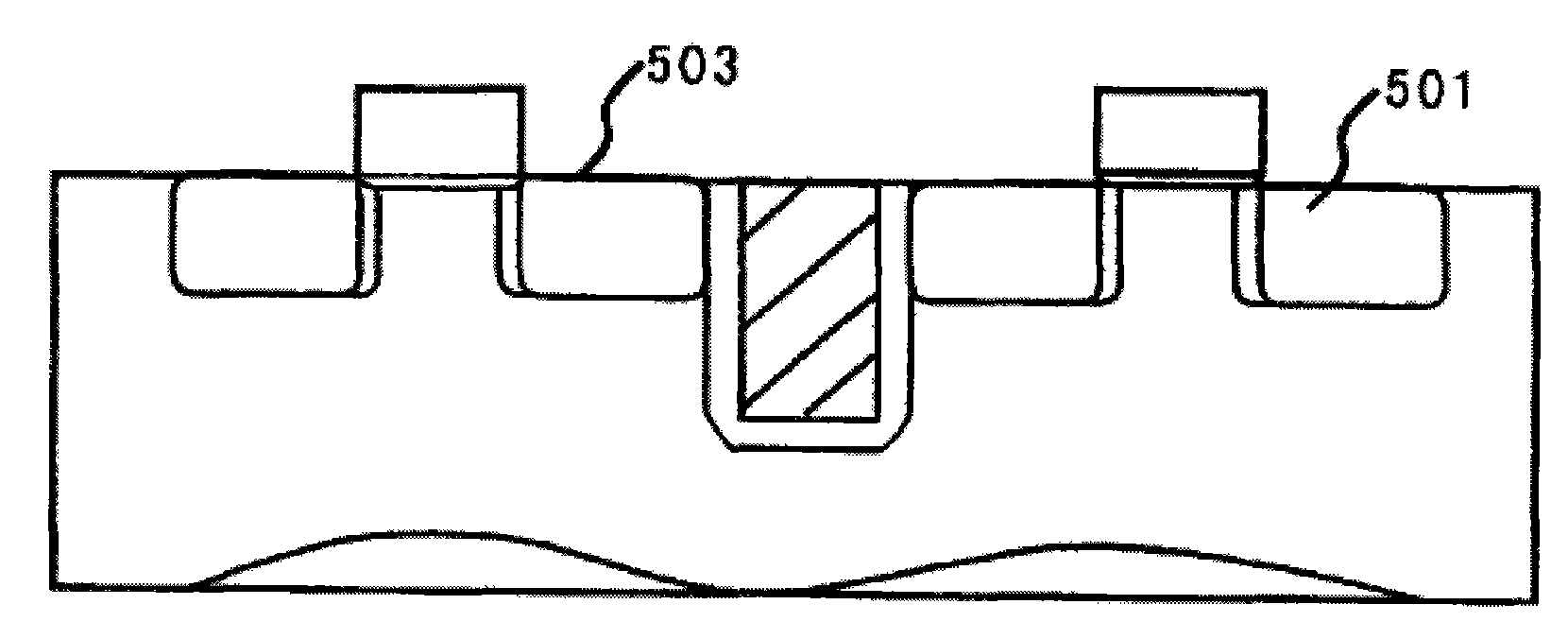

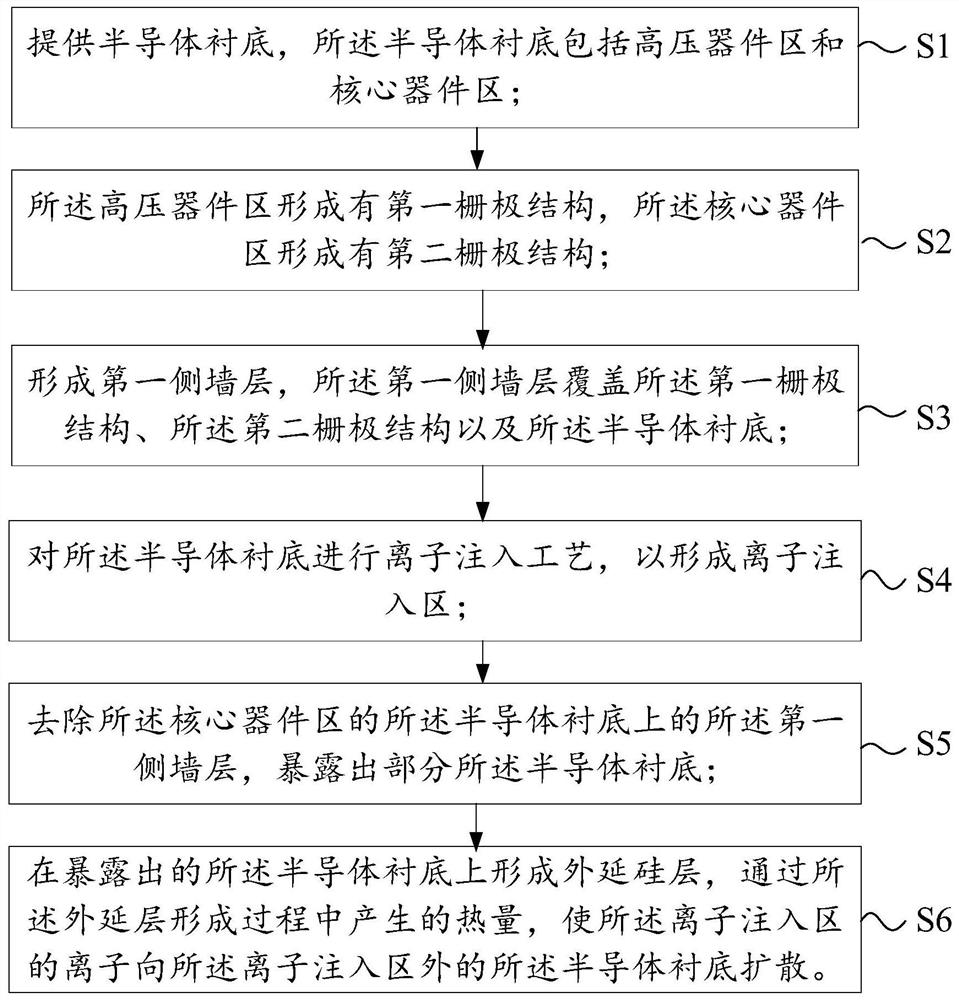

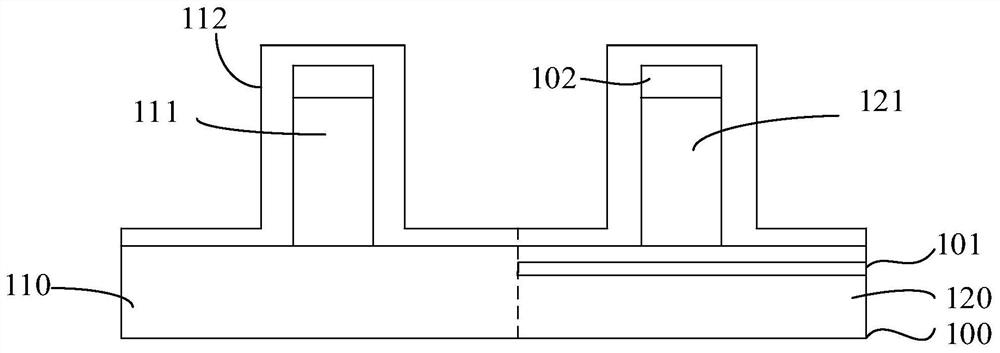

Method for manufacturing MOS device

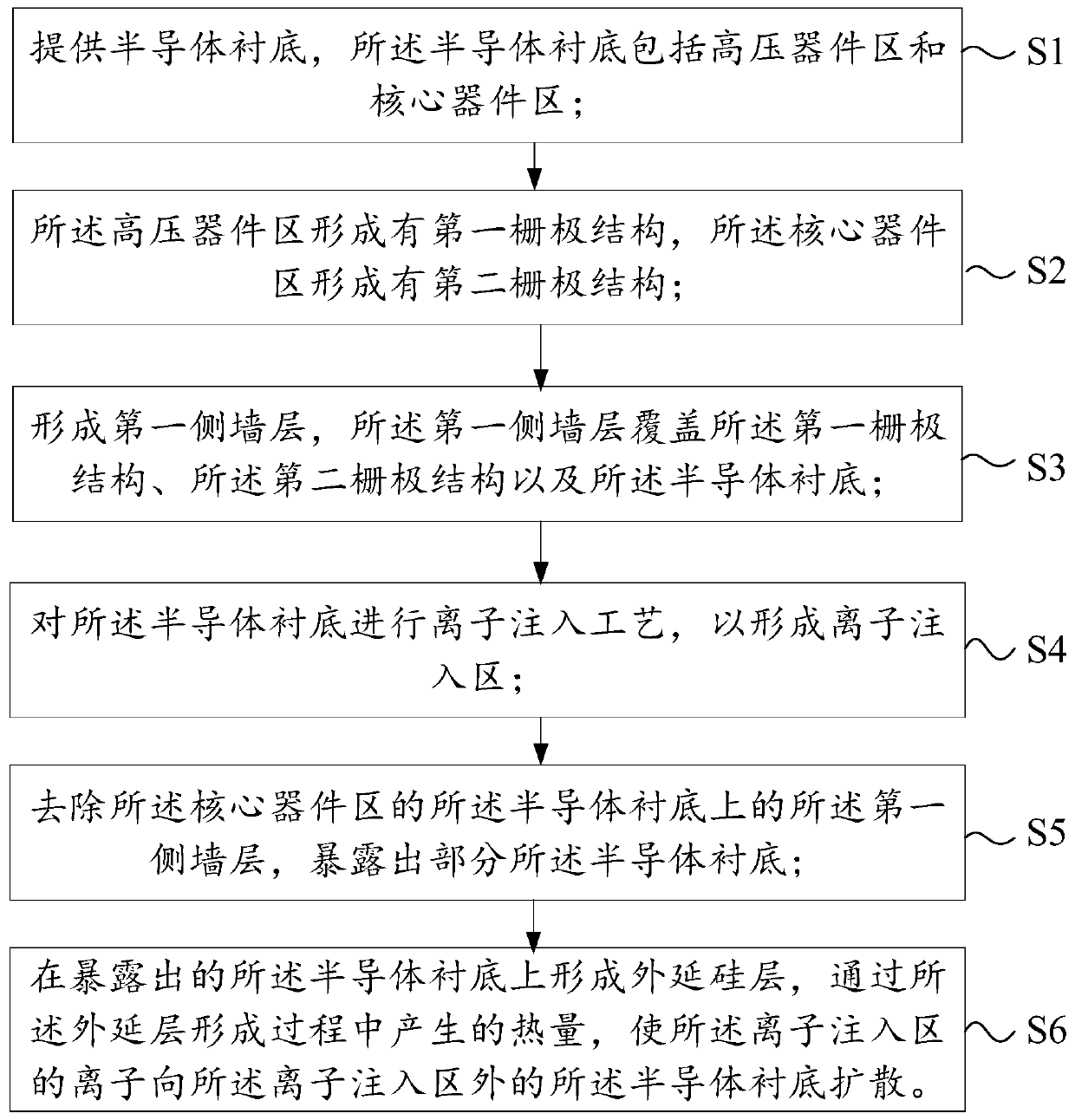

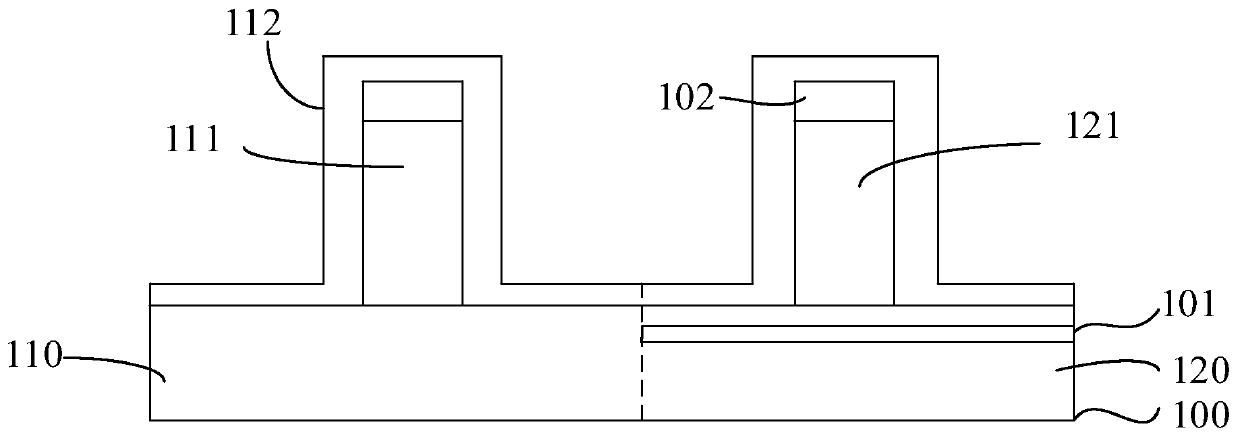

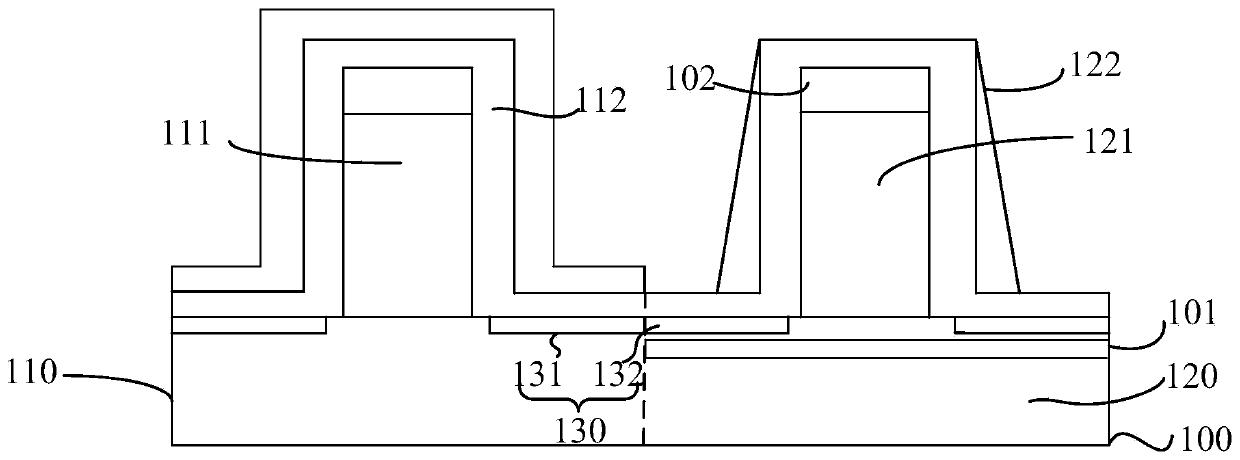

ActiveCN110867412AImprove performanceSuppress injection effectTransistorSemiconductor/solid-state device manufacturingEngineeringIon implantation

A method for manufacturing a MOS device provided by the present invention comprises: forming a first spacer layer covering a first gate structure, a second gate structure, and a semiconductor substrate; performing an ion implantation process on the semiconductor substrate to form an ion implantation region; removing the first spacer layer on the semiconductor substrate in a core device region to expose a portion of the semiconductor substrate; forming an epitaxial silicon layer on the exposed semiconductor substrate, wherein heat is generated during the growth of the epitaxial silicon layer, and ions in the ion implantation region can diffuse to the semiconductor substrate outside the ion implantation region. Thus, the method can replace an annealing process to suppress a hot carrier injection effect and improve the performance of the device. In addition, since a subsequent annealing process is eliminated, processing time can be saved.

Owner:SHANGHAI HUALI MICROELECTRONICS CORP

Laser hardening process of perforated plugs without preheating before laser cladding

ActiveCN103572280BHigh surface hardnessImprove surface wear resistanceMetallic material coating processesHigh intensityHardness

Owner:JIANGSU ZHONGOU FERTILIZER

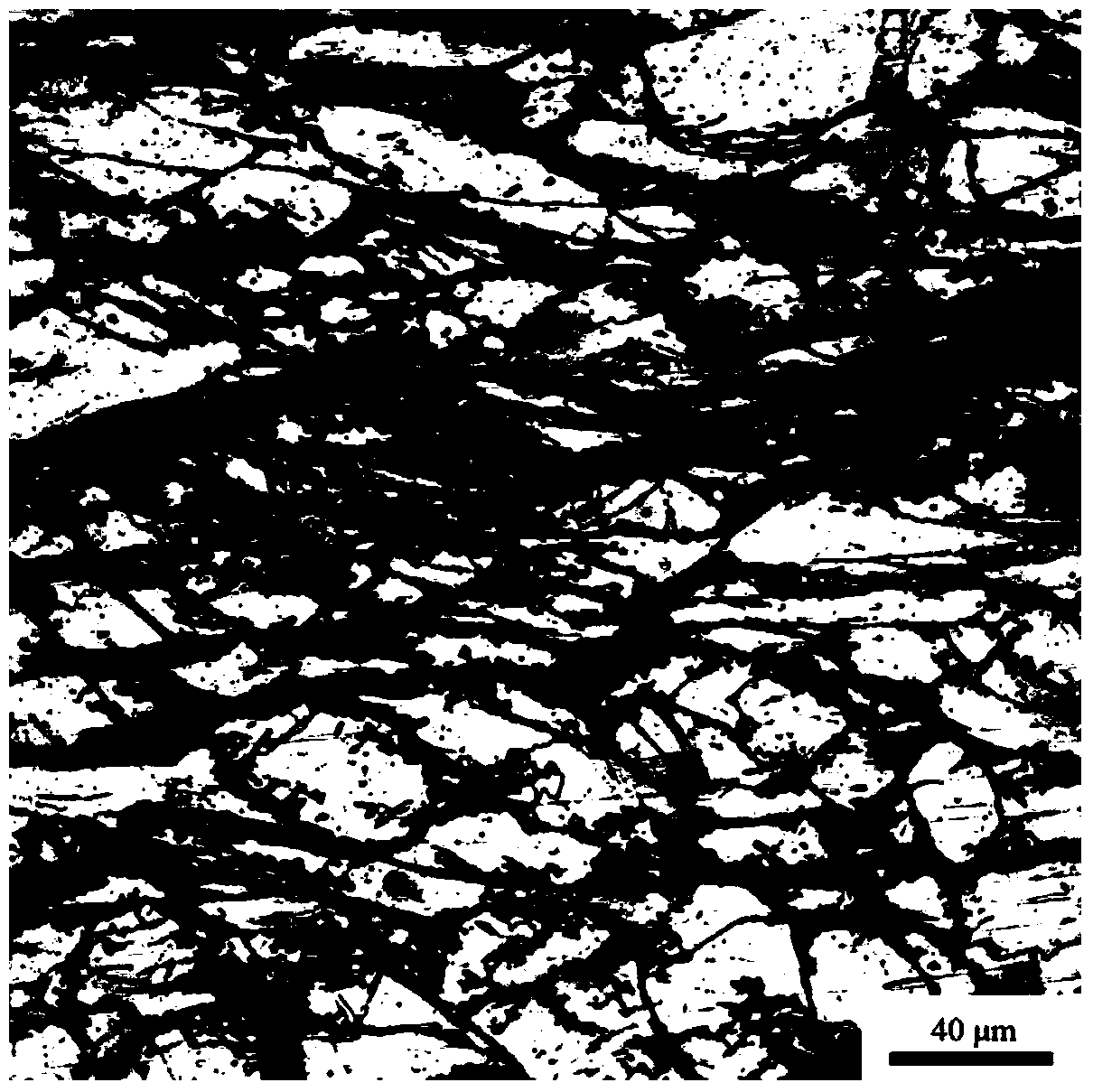

Method for producing medium-carbon steel deformation induced ferrite

ActiveCN100432244CReduce intensityReduce hardnessHeat treatment process controlSlow coolingPrecipitation

Production of medium-carbon steel deformation induced ferrite by excess precipitation is carried out by heating medium-carbon steel deformation at 1190-1230degree, 1-body frame first pressing by high-speed wire-rod production line, 12-body frame medium pressing and 4 / 8 body frame pre-fine pressing, controlled cooling at 0.2-15degree / s, fast phase changing at 660-700degree, isothermal or slow-cooling treating and naturally cooling to normal temperature. Accumulation draft is 50-80%, deformation speed-ration is 10-30 / s, precipitation content reaches to 60-65%. It saves energy resources and has less environmental pollution.

Owner:MAANSHAN IRON & STEEL CO LTD

Stress NMOS device and manufacturing method of stress CMOS

ActiveCN101593701BImprove stabilityIncrease stressSemiconductor/solid-state device manufacturingDevice formEngineering

A manufacturing method of a stress NMOS device comprises the followings: semiconductor substrates with grid structures are offered; a source electrode and a drain electrode are formed in the semiconductor substrates at two sides of the grid structures; wherein after the grid structures are formed and before the source electrode and the drain electrode are formed, or after the source electrode andthe drain electrode are formed, the method further comprises the following steps: ions are implanted, and carbon impurities are doped in the semiconductor substrates at two side of the grid structures; solid phase epitaxy process is carried out to facilitate the carbon impurities react with silicon to form a strain silicon carbide layer. The invention also provides a manufacturing method of the stress CMOS device. Carbon in the strain silicon carbide layer in the stress MOS device formed by the invention has comparatively high content, the stress applied to an NMOS conducting channel by an epitaxial layer of a silicon carbide material is greatly increased; the mobility of carriers can be effectively improved, thus enlarging the drive current and improving the performance of the NMOS device.

Owner:SEMICONDUCTOR MANUFACTURING INTERNATIONAL (BEIJING) CORP

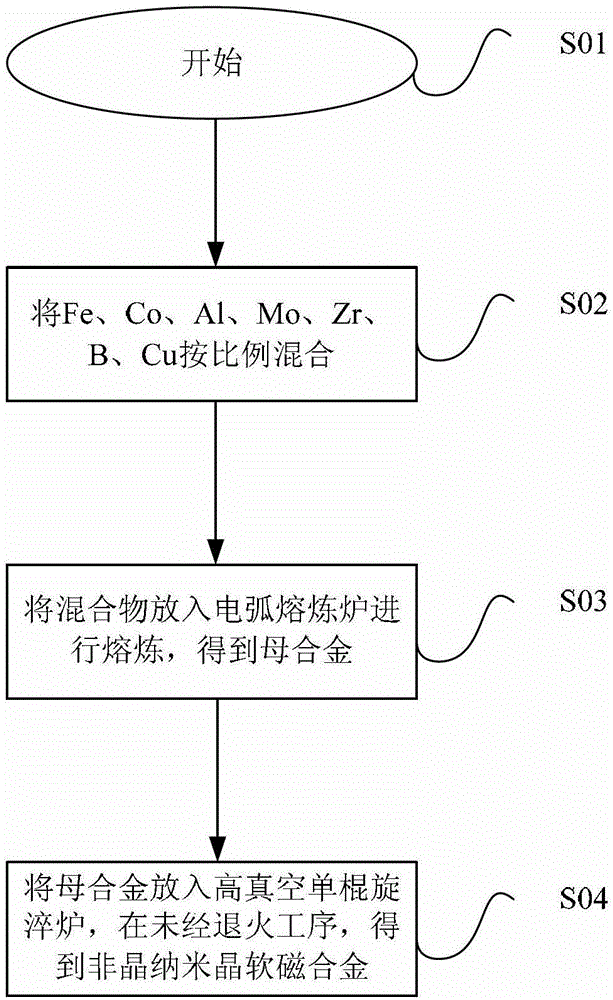

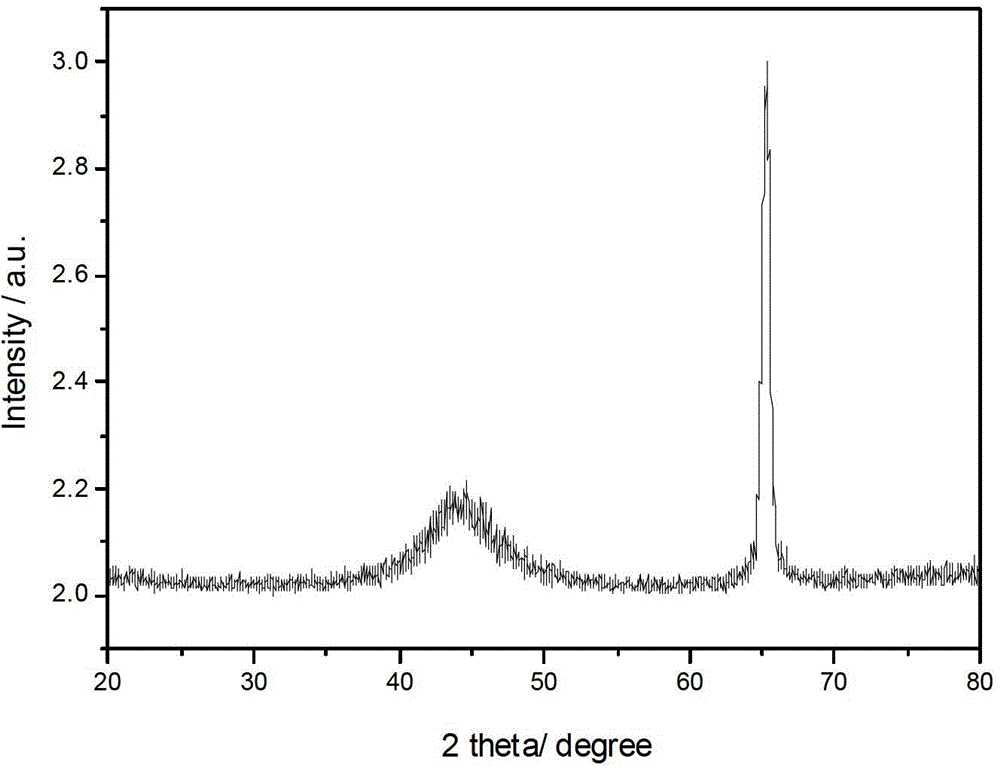

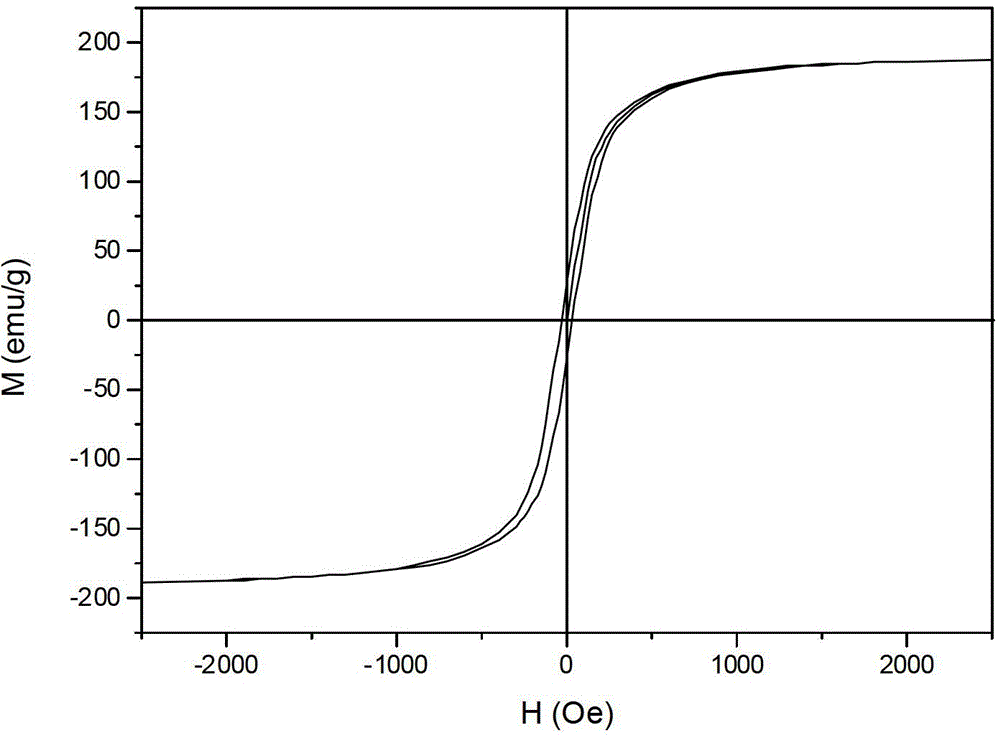

Amorphous nanocrystalline magnetically soft alloy and preparation method thereof

InactiveCN103060723BImprove surface qualityGood bending toughnessMagnetic materialsDistribution transformerChemical composition

The invention relates to an amorphous nanocrystalline magnetically soft alloy and a preparation method of the magnetically soft alloy. The amorphous nanocrystalline magnetically soft alloy comprises the following chemical components in percentage by atom: 39-44 of Fe, 39-44 of Co, 0-4 of Al, 0.6-1.5 of Mo, 5.5-7.4 of Zr, 3.6-5.5 of B and 0.5-1.4 of Cu. Compared with traditional iron-based amorphous, nanocrystalline magnetically soft alloys and the like, the amorphous nanocrystalline magnetically soft alloy has the advantages that a precious metal Nb is replaced by cheap Al, and simultaneously, a part of precious metal B is replaced by cheap Zr; an amorphous nanocrystalline ribbon in a quenching state is obtained by particularly adjusting the chemical components and optimizing a belt technology; a complicated annealing process is omitted, and the cost of amorphous nanocrystalline soft magnetic material is greatly reduced. The amorphous nanocrystalline magnetically soft alloy is simple in technology, low in cost and easy to industrialize; the obtained product has high saturation induction intensity, so that the magnetically soft alloy can be used for national defense and civilian industry products such as a distribution transformer, a motor magnetic core and a high-power switching power supply.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

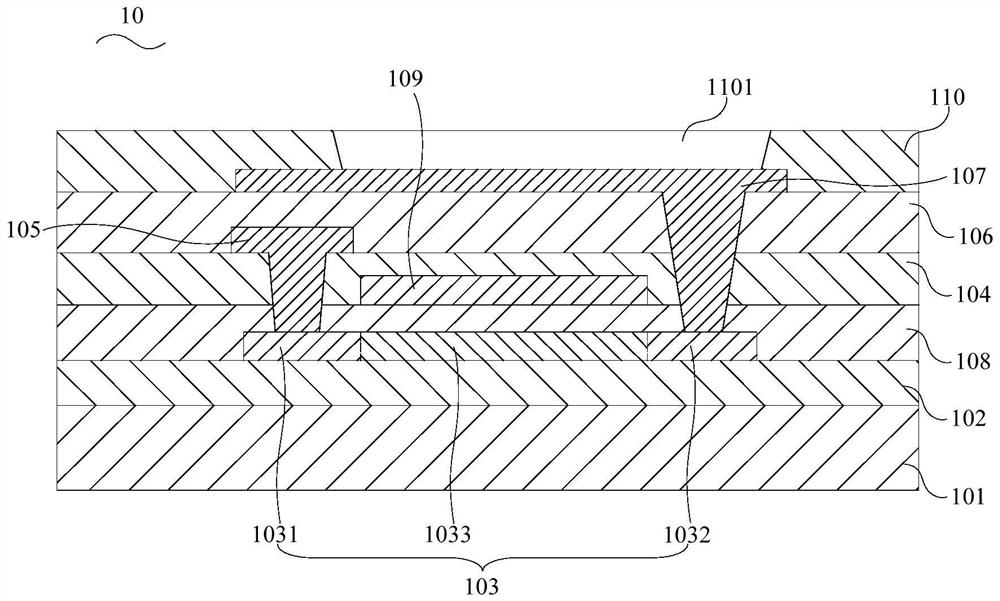

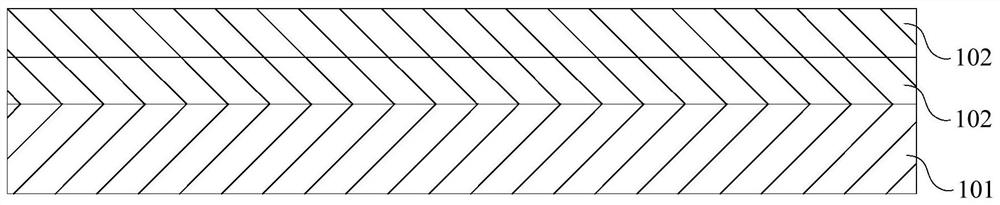

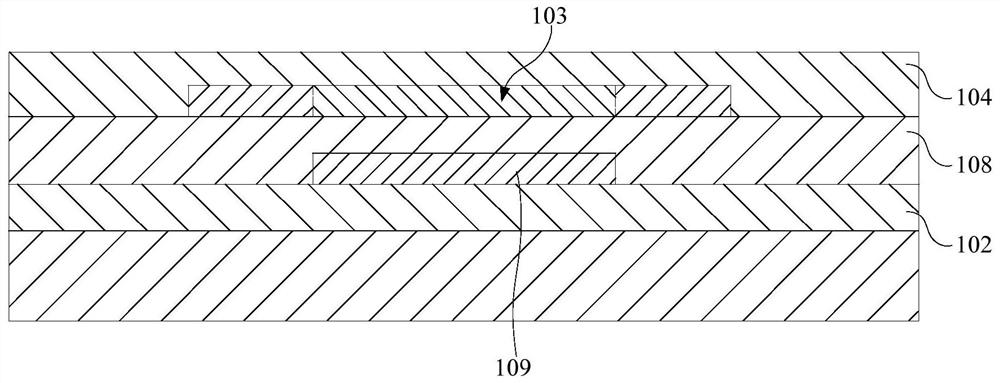

A kind of array substrate and preparation method thereof

ActiveCN109037234BAvoid contact resistanceImprove conductivitySolid-state devicesSemiconductor/solid-state device manufacturingEngineeringActive layer

The invention provides an array substrate and a preparation method thereof. Through the array substrate, compared with the prior art, by forming a drain pattern layer in contact with the other end ofan active layer, and then forming a pixel electrode layer in contact with the drain pattern layer, conduction between the pixel electrode layer and the other end of the active layer is realized, in the embodiment, a pixel electrode layer in direct contact with the other end of the active layer is formed, the is, the drain pattern layer and the pixel electrode layer in the prior art are prepared atone time, As the contact resistance generate by the contact between the drain pattern layer and the pixel electrode lay in the prior art is avoided, the electrical conductivity is improved, and an annealing process carried out to increase the good contact between the drain pattern layer and the pixel electrode layer is omitted, thereby simplifying the process steps.

Owner:WUHAN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

High-sulfur alloy steel roll and production method

InactiveCN102628147BHigh temperature resistantSelf-lubricatingRollsElectric furnaceChemical compositionSulfur

The invention relates to a high-sulfur alloy steel roll and a production method. The high-sulfur alloy steel roll comprises the following chemical components by weight percent: 0.4%-1.0% of C, 0.5%-1% of Si, 0.5%-1% of Mn, 1.5%-10% of S, less than 0.05% of P, 4%-6% of Cr, 0.05%-1.5% of V, 0.1%-0.4% of Mo, less than 2% of W, 0.05%-0.1% of Ti, 0.005%-0.1% of Ba, less than 0.05% of Re, and the balance of Fe. The acknowledged rule that sulfur cannot exceed 0.03% is broken by the high-sulfur alloy steel roll; harmful elements are converted into beneficial elements; the produced high-sulfur alloy steel roll has the advantages of high-temperature resistance, self-lubricating property, abrasion resistance, and the like; no lubrication or less lubrication is required by the roll during application process, so that the working strength of workers is relieved; the rare metal Co is not contained, so that the production cost is lowered; an intermediate frequency furnace is used for melting; a horizontal centrifuge is used for pouring; a common high-temperature resistance furnace is used for performing thermal treatment; the equipment investment is less; the processing technology is free from annealing process; the production technology is simple and reasonable; and the production efficiency is greatly increased.

Owner:常熟市轧辊厂限公司

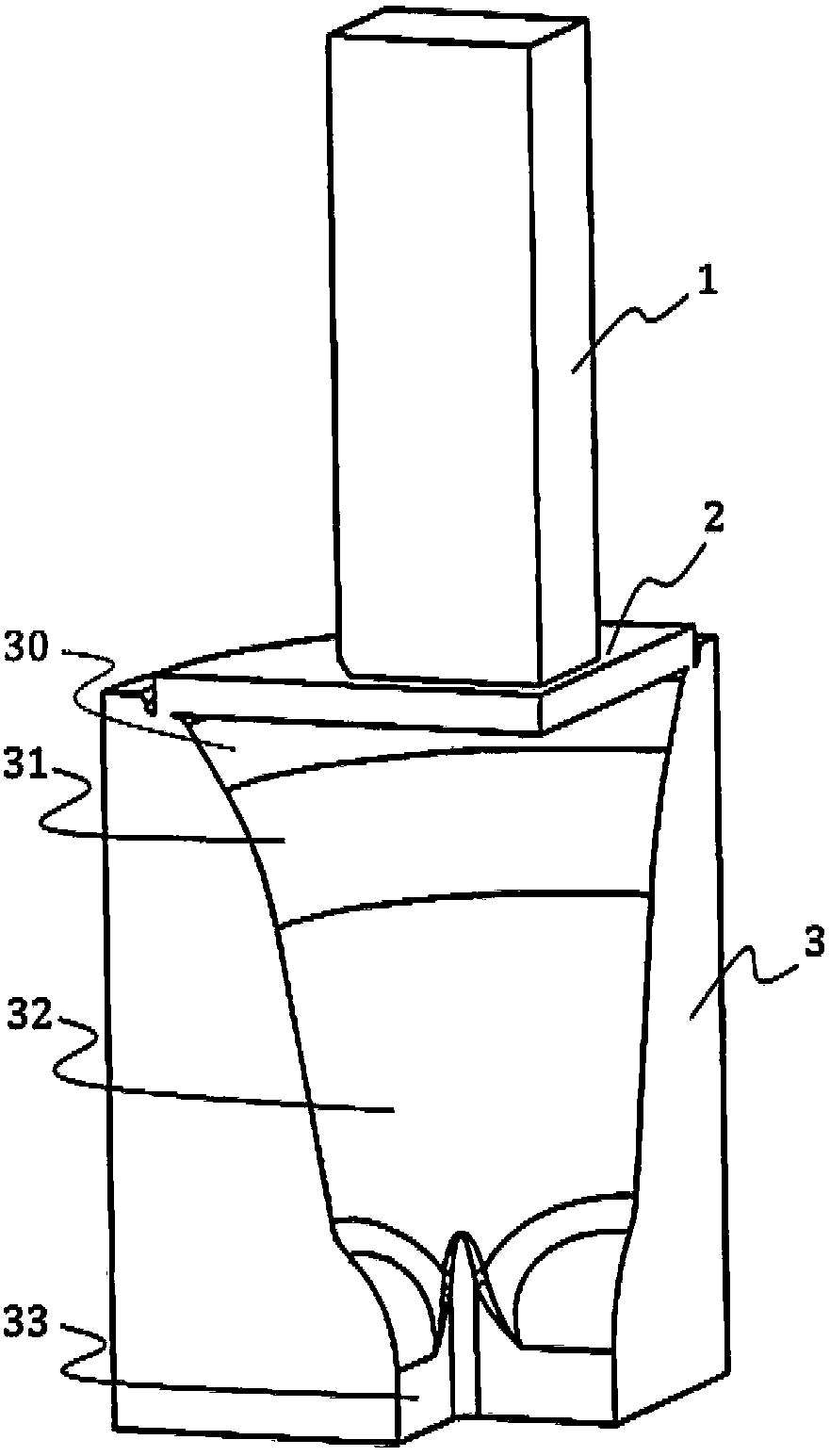

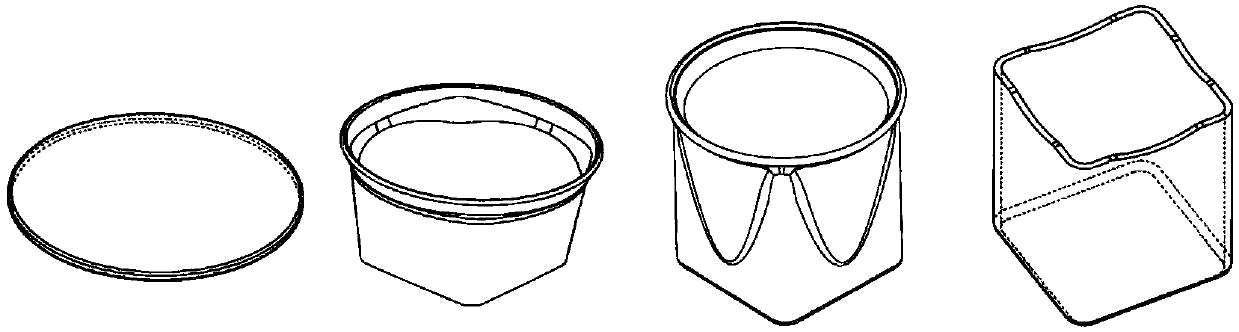

Manufacturing device and process of one-stroke drawn high square box-shaped pieces for titanium alloy sheets

ActiveCN110834046AExtend your lifeEliminate the annealing processShaping toolsHollow articlesEngineeringTitanium alloy

The invention discloses a manufacturing device and process of one-stroke drawn high square box-shaped pieces for titanium alloy sheets. Through a conical female die of a two-section structure, manufacturing is completed in various types of biconical female dies through one process step; the one-stroke drawn high square box-shaped pieces can be formed by circular blanks in the biconical female diesthrough square male dies under the condition of blank pressing without blank holders, the upper parts of the female dies are biconical, and the lower parts of the female dies are square; and at the moment, the intersecting lines of the conical surfaces and straight wall planes of the square parts form hyperbolically-drawn edges.

Owner:ZHEJIANG SHENJI TITANIUM IND

MOS device manufacturing method

ActiveCN110867412BImprove performanceSuppress injection effectTransistorSemiconductor/solid-state device manufacturingEngineeringIon implantation

In the manufacturing method of the MOS device provided by the present invention, by forming a first spacer layer, the first spacer layer covers the first gate structure, the second gate structure and the semiconductor substrate; performing an ion implantation process on the semiconductor substrate to form an ion implantation region; removing the first sidewall layer on the semiconductor substrate in the core device region to expose part of the semiconductor substrate; An epitaxial silicon layer is formed on the semiconductor substrate, heat is generated during the growth process of the epitaxial silicon layer, and ions in the ion implantation area can diffuse to the semiconductor substrate outside the ion implantation area. Therefore, the annealing process can be replaced, thereby suppressing the hot carrier injection effect and improving the performance of the device. In addition, because the subsequent annealing process is omitted, processing time can be saved.

Owner:SHANGHAI HUALI MICROELECTRONICS CORP

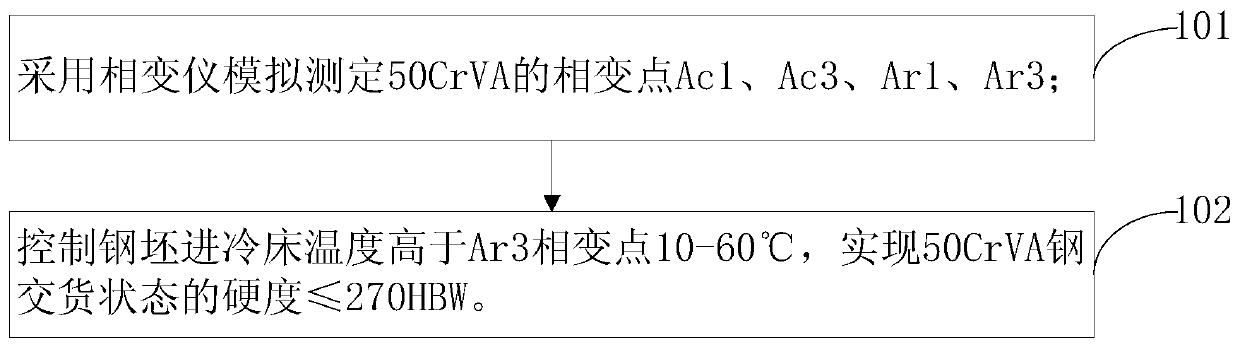

A method of regulating and controlling the hardness of alloy structural steel 50crva

The invention provides a method for regulating and controlling the hardness of alloy structural steel 50CrVA. The method is especially suitable for the hardness regulation and control of 50CrVA rolledround steel with the specification being equal to and less than 60 mm and includes the steps that the temperature of steel billet entering a cold bed after rolling is controlled to be 10-60 DEG C higher than the Ar3 phase change point, and the fact that the hardness of the 50CrVA steel in a factory delivery state is equal to and less than 270 HBW is achieved. By means of the method, the fact thatthe factory delivery hardness is equal to and less than 270 HBW can be achieved, the utilization rate of downstream customers for the whole material is improved, the annealing process of the 50CrVA rolled round steel in existing processes is eliminated, and the use cost of the material is reduced.

Owner:DAYE SPECIAL STEEL CO LTD

High intensity, corrosion resistant and high ductility steel for mooring chain and production process thereof

InactiveCN100516275CEliminate the annealing processAvoid problemsRoll mill control devicesMetal rolling arrangementsCrazingChemical composition

The invention discloses a high-strength corrosion resistant high-tenacity steel which is used for mooring chain and a production process hereof; the chemical components (wt percent) are: 0.18 percent to 0.25 percent of C, 0.10 percent to 0.35 percent of Si, 1.40 percent to 1.80 percent of Mn, 0.80 percent to 1.40 percent of Cr, 0.60 percent to 1.20 percent of Ni, 0.40 percent to 0.70 percent of Mo, 0.02 percent to 0.06 percent of Nb, 0.02 percent to 0.06 percent of Al, S which is less than or equal to 0.010 percent, P which is less than or equal to 0.020 percent, B which is less than or equal to 0.005 percent, Cu which is less than or equal to 0.20 percent, Sb which is less than or equal to 0.010 percent, Sn which is less than or equal to 0.03 percent, As is less than or equal to 0.04 percent, [O] which is less than or equal to 0.0018 percent, [N] which is less than or equal to 0.0060 percent and the rest is Fe. The invention avoid producing martensite tissue with optimized design of components and in this way the material tissue can not be converted to produce central crack in a long-term placement under the situation that the parent metal does not adopt annealing process; at the same time the precious metal Ni is saved. The invention adopts RH / VD for desaeration and removing impurities and in this way, the purity of the steel can be obviously increased; the invention adopts converter for melting which reduces the energy consumption and saves cost.

Owner:JIANGSU SHAGANG GROUP HUAIGANG SPECIAL STEEL CO LTD

A laser cladding method for perforated plug surface

ActiveCN103572282BHigh surface hardnessImprove surface wear resistanceMetallic material coating processesHigh intensityHardness

The invention relates to a laser strengthening process of a piercing plug. The laser strengthening process is characterized by firstly carrying out laser cladding on a transition alloy layer on the surface of a piercing plug matrix and then carrying out laser cladding on a high-strength alloy layer on the transition alloy layer, wherein the alloy powder adopted by the transition alloy layer is the nickel base alloy; the alloy powder adopted by the high-strength alloy layer is the cobalt base alloy. The laser strengthening process has the beneficial effects that the transition alloy layer in the process has lower hardness than the high-strength alloy layer, plays a role in transition for the high-strength alloy layer with high hardness and high wear resistance and can well relieve the surfacing stress, so that even if the plug is not preheated or annealed, the residual surfacing stress can not have great impacts on the tissues of a laser cladding layer, thus effectively avoiding impacting the properties of the cladding layer by annealing, substantially improving the surface hardness and wear resistance of the piercing plug, simultaneously omitting the processes of preheating and annealing and also improving the production efficiency.

Owner:JIANGSU ZHONGOU FERTILIZER

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com