Heat-resistant steel for corrosion-resistant high-pressure boiler pipe and production method thereof

A technology for a high-pressure boiler and a production method, which is applied in the field of heat-resistant steel for corrosion-resistant high-pressure boiler tubes, can solve problems such as poor H2S corrosion resistance, and achieve the effects of reducing production costs, eliminating annealing procedures, and eliminating internal stress.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

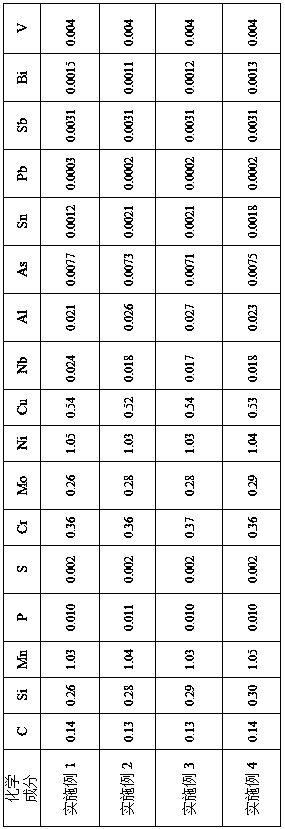

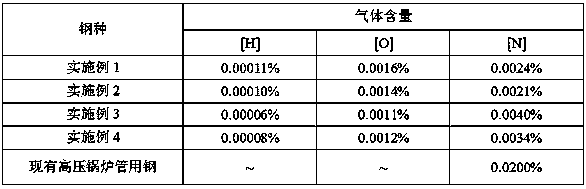

Examples

Embodiment Construction

[0074] 1) Molten iron transfer: A new type of molten iron ladle and its covered heat preservation device are used to transfer molten iron to reduce heat loss, facilitate pretreatment of molten iron, and improve smelting temperature conditions;

[0075]2) KR desulfurization: use the stirring head to stir clockwise in the ladle to make the molten iron form a vortex, put 450~900Kg self-made desulfurizer into the vortex at one time, stir for 12~15 minutes according to the sulfur content of the molten iron, and make the desulfurizer and molten iron The sulfur fully reacts, and then removes the desulfurization products through the slag remover, reduces the S content of the molten iron, and ensures that the S of the molten iron after desulfurization is ≤0.003%;

[0076] 3) Converter smelting: smelting in a top-bottom combined blowing converter with a capacity of more than 100 tons, using 85% molten iron and 15% high-quality scrap steel as raw materials for primary smelting to achieve ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com