A method of regulating and controlling the hardness of alloy structural steel 50crva

A technology for alloy structural steel and hardness, which is applied in the field of adjusting and controlling the hardness of alloy structural steel 50CrVA, which can solve the problems of low overall material utilization rate and high processing difficulty, and achieve the effects of eliminating annealing process, improving utilization rate and reducing use cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

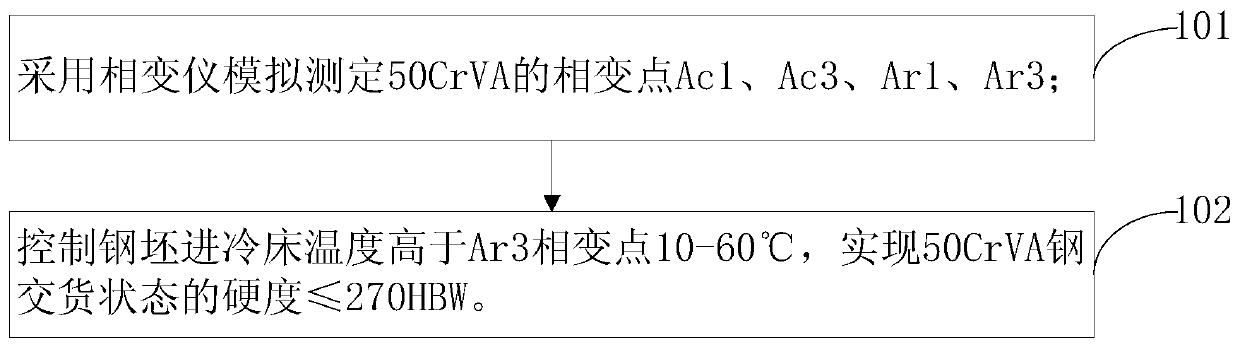

Method used

Image

Examples

Embodiment 1

[0042] The concrete composition of the 50CrVA steel that present embodiment provides is as follows:

[0043] C: 0.49, Si: 0.26, Mn: 0.7, P: 0.015, S: 0.003, Cr: 1.00, Ni: 0.04, Cu: 0.09, V: 0.152.

[0044] The phase transition points measured by DIL805L static phase transition instrument are: Ac1: 766°C, Ac3: 786°C, Ar1: 648°C, Ar3: 680°C.

[0045] In the above-mentioned embodiment, the above-mentioned material is firstly heated by a heating furnace, and then rolled by a step-by-step 26-stand continuous rolling mill.

[0046] Specifically, the above materials are used to make three round steel billets of the same specification, which are respectively rolled and tested on the upper cooling bed. At the same position of the three billets, water cooling before final rolling and water cooling before entering the cooling bed are carried out respectively. The final test results are as follows:

[0047] Specifications / mm P3 / ℃ P4 / ℃ P5 / ℃ P6 / ℃ Hardness / HBW 50 825 ...

Embodiment 2

[0049] C: 0.5, Si: 0.29, Mn: 0.74, P: 0.015, S: 0.004, Cr: 1.02, Ni: 0.05, Cu: 0.12, V: 0.144.

[0050] The phase transition points measured by DIL805L static phase transition instrument are: Ac1: 770°C, Ac3: 789°C, Ar1: 652°C, Ar3: 683°C.

[0051] In the above-mentioned embodiment, the above-mentioned material is firstly heated by a heating furnace, and then rolled by a step-by-step 26-stand continuous rolling mill.

[0052] Specifically, the above materials are used to make three round steel billets of the same specification, which are respectively rolled and tested on the upper cooling bed. At the same position of the three billets, water cooling before final rolling and water cooling before entering the cooling bed are carried out respectively. The final test results are as follows:

[0053] Specifications / mm P3 / ℃ P4 / ℃ P5 / ℃ P6 / ℃ Hardness / HBW 50 827 794 880 683 310 50 847 814 900 718 268 50 876 825 889 741 268 50 874 825 88...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com