Method for manufacturing cmos image sensor

A technology of image sensor and manufacturing method, applied in semiconductor/solid-state device manufacturing, semiconductor device, electric solid-state device, etc., can solve the problems of reduced device yield and defective devices, reduce thermal budget, prevent interconnection delamination, etc. , Improve the effect of dark characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

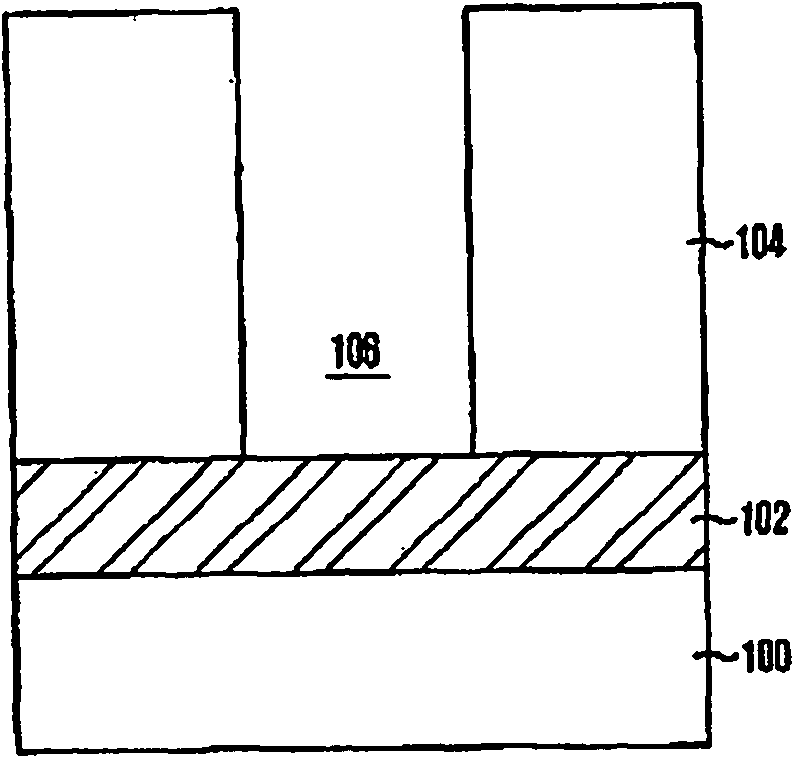

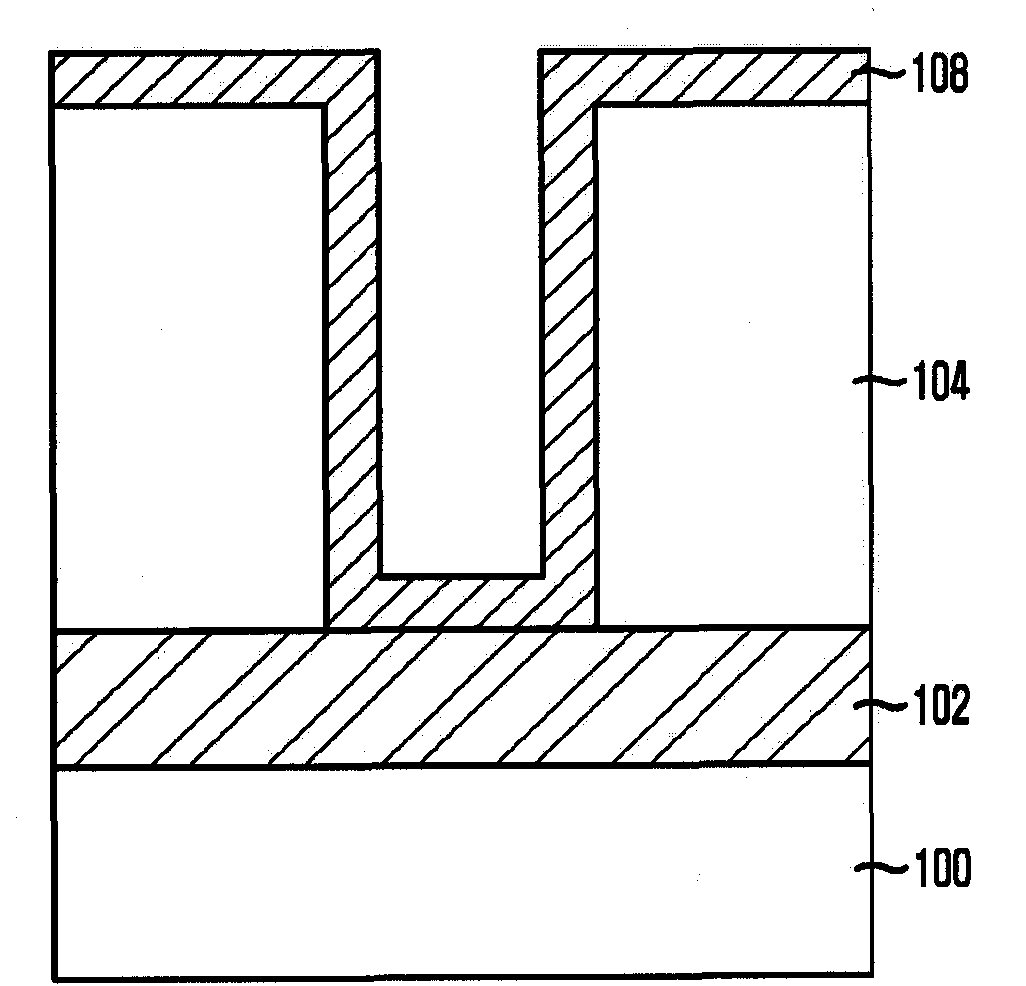

[0026] Figures 2 to 8 is a cross-sectional view illustrating a method of manufacturing a CMOS image sensor according to an embodiment of the present invention.

[0027] Such as figure 2 As shown, a first metal interconnection 102 is formed on a substrate 100 including a semiconductor structure including a plurality of transistors and a photodiode serving as a light receiving device. In this case, the first metal interconnection 102 may include one selected from the group consisting of aluminum (AL), copper (Cu), tungsten (W), or platinum (Pt). Preferably, the first metal interconnection 102 includes Al.

[0028] Then, an insulating interlayer 104 is formed on the substrate 100 to cover the first metal interconnection 102 . In this case, the interlayer insulating layer 104 includes oxide, preferably, silicon oxide (SiO 2 ). For example, the interlayer insulating layer 104 may include a material made of BPSG (borophosphosilicate glass) film, PSG (phosphosilicate glass) fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com