Method for producing highly-reaming hot-dip galvanized sheet with tensile strength of 540 MPa

A hot-dip galvanized sheet, tensile strength technology, applied in hot-dip galvanizing process, coating, metal material coating process, etc. The effect of eliminating the heating process of the heating furnace and reducing the energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-4

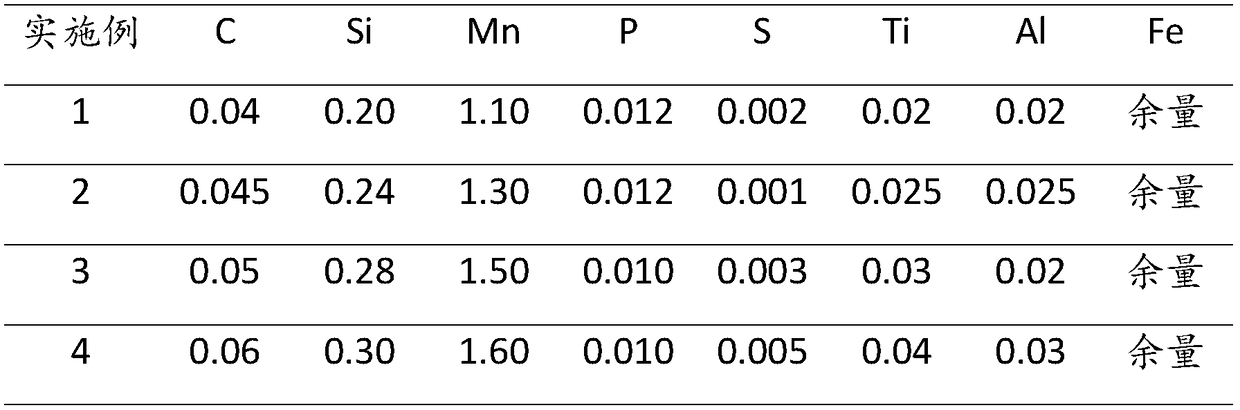

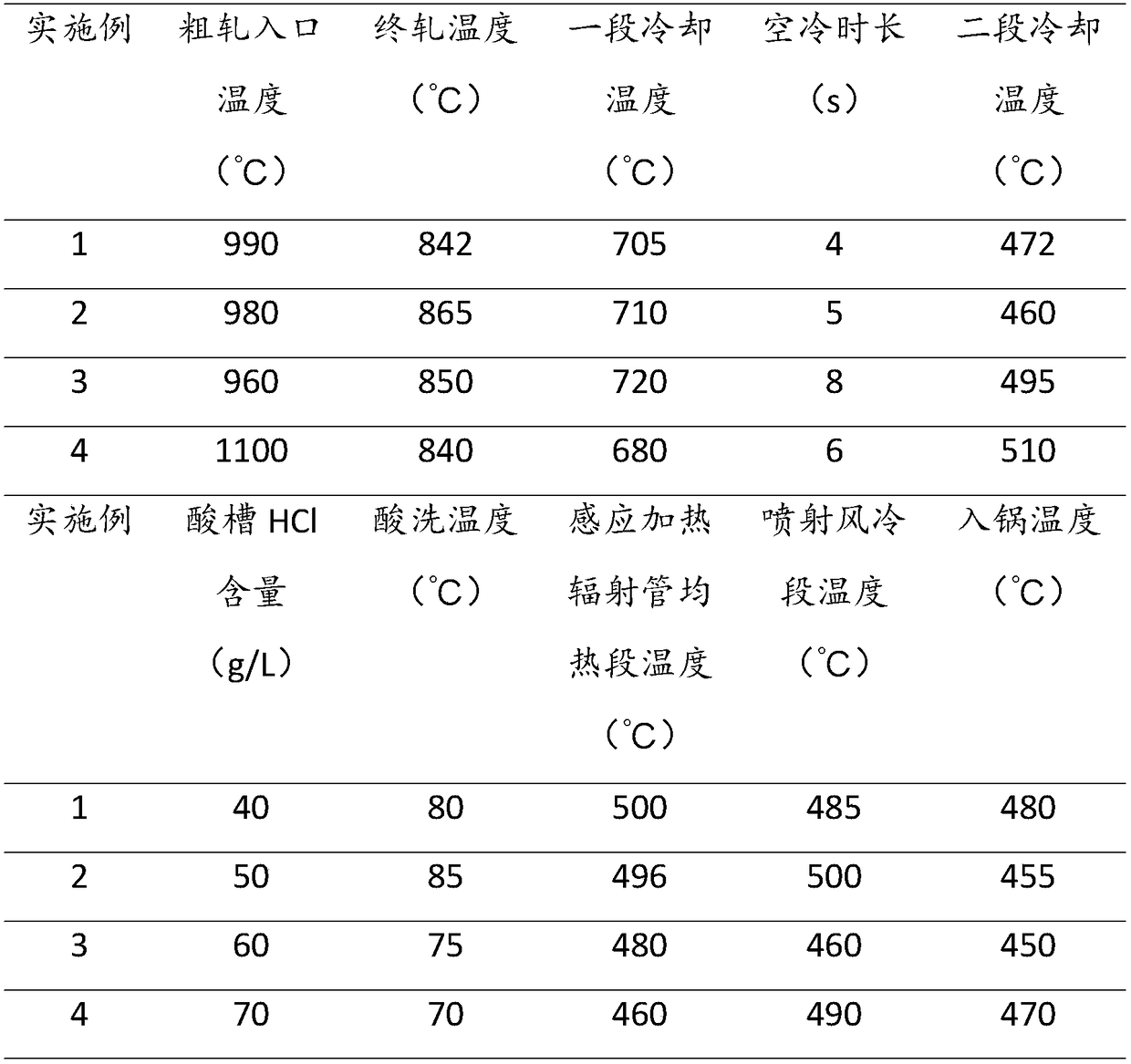

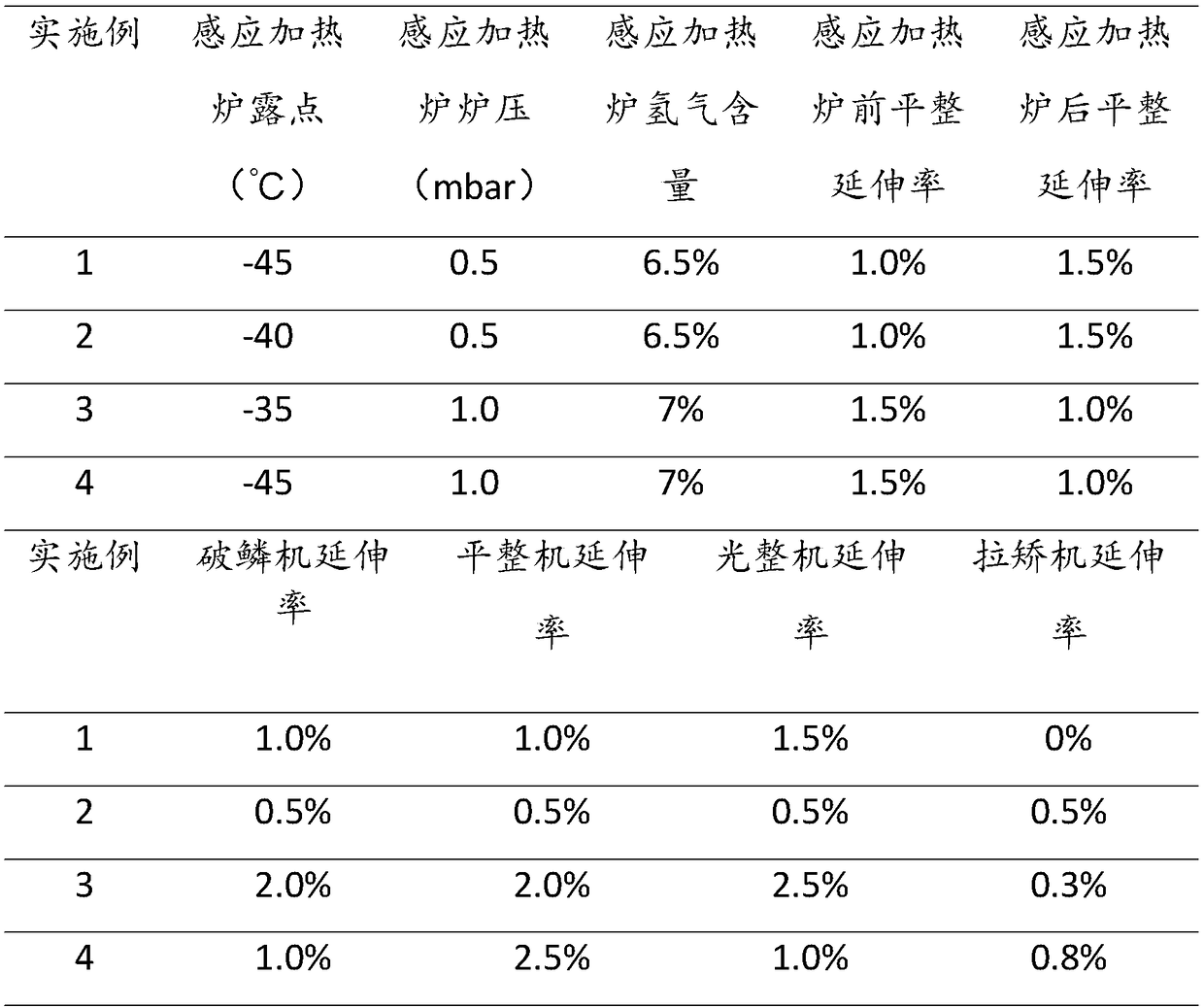

[0030]The technological process of the method for producing the hot-dip galvanized sheet with high tensile strength of 540MPa and high expansion hole of the present invention is: first prepare the molten iron of required composition, wherein the composition of the molten iron of each embodiment is as shown in Table 1 (unit is wt.%) , pretreatment of molten iron, converter steelmaking and LF furnace refining, and then enter the ESP production line to produce hot-rolled strip steel. In the ESP production line, the molten iron is refined by RH furnace, cast by continuous casting machine, rough rolled by rough rolling mill, pendulum shear, stacker, rotary hub type flying shear, electromagnetic induction heating, high pressure water descaling and finish rolling. The hot-rolled steel strip is then coiled and put into storage after undergoing segmental layer cooling to obtain hot-rolled raw material coils. After inspection, the hot-rolled raw material coils are transferred to the con...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com