Manufacturing device and process of one-stroke drawn high square box-shaped pieces for titanium alloy sheets

A technology for single-stroke, box-shaped parts, applied in the direction of manufacturing tools, metal processing equipment, applications, etc., to achieve the effects of reducing tensile force, eliminating blank holders, and reducing stress-strain values of dangerous sections

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

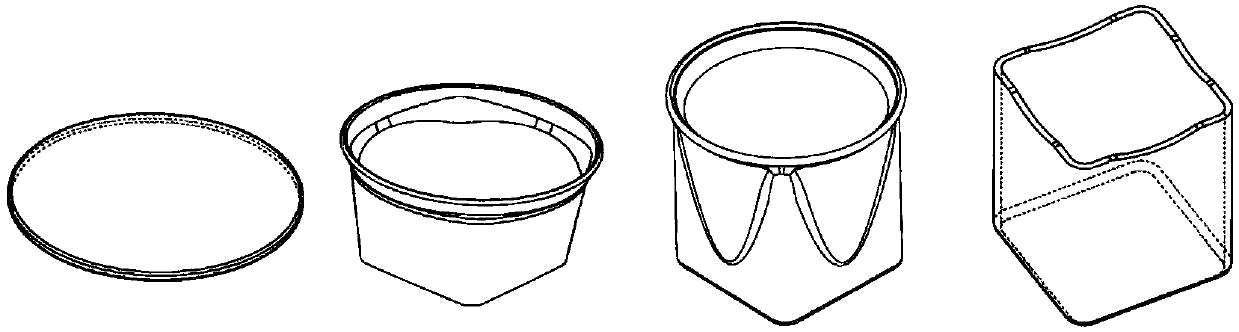

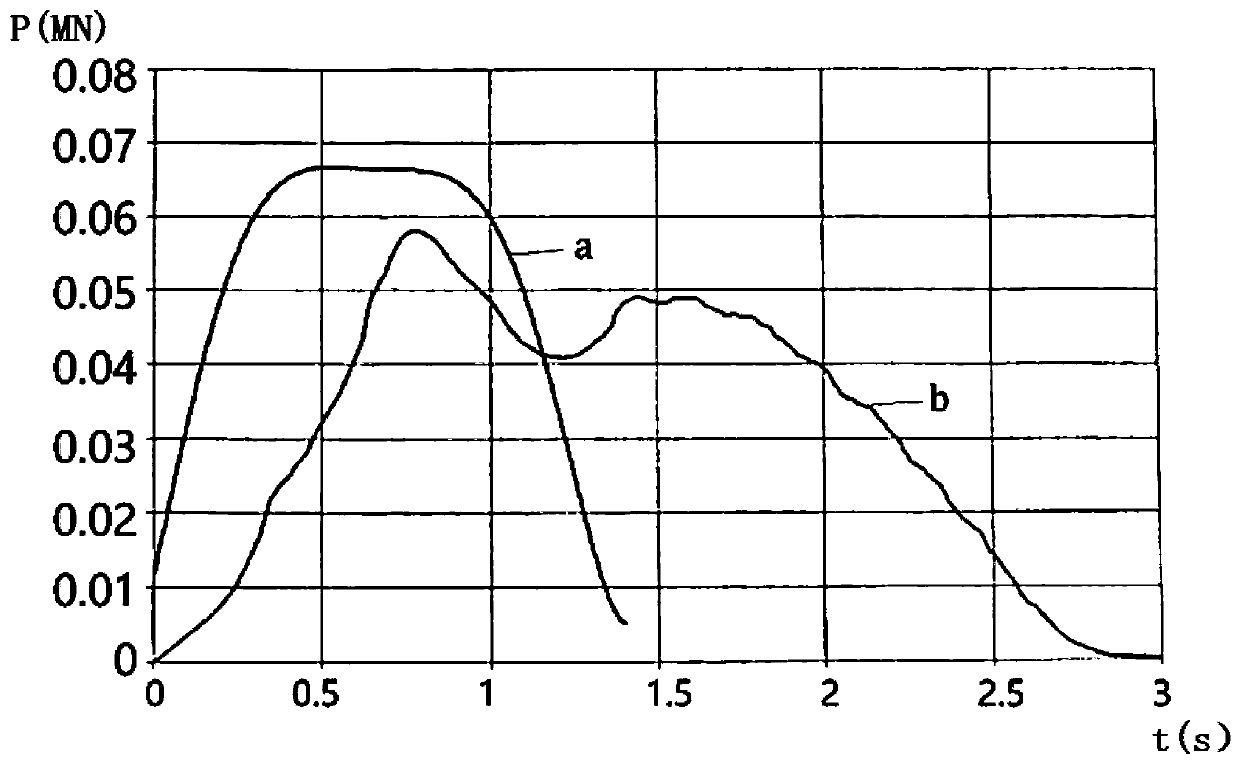

[0020] In this embodiment, TA1 industrial pure titanium plate is used to draw into a square box-shaped part: the side length is 45mm, the height is 50mm, and it is cut into a round blank by ordinary punching machine. Select a hydraulic press with a nominal force of 50MN and a hydraulic press with a slider speed of 50mm / s. The friction coefficient of material contact boundary and mold adopts μ=0.15. According to the recommendation of the current die design manual, the total drawing coefficient m=0.52 and the relative thickness of the blank (s / D)×100=1.36.

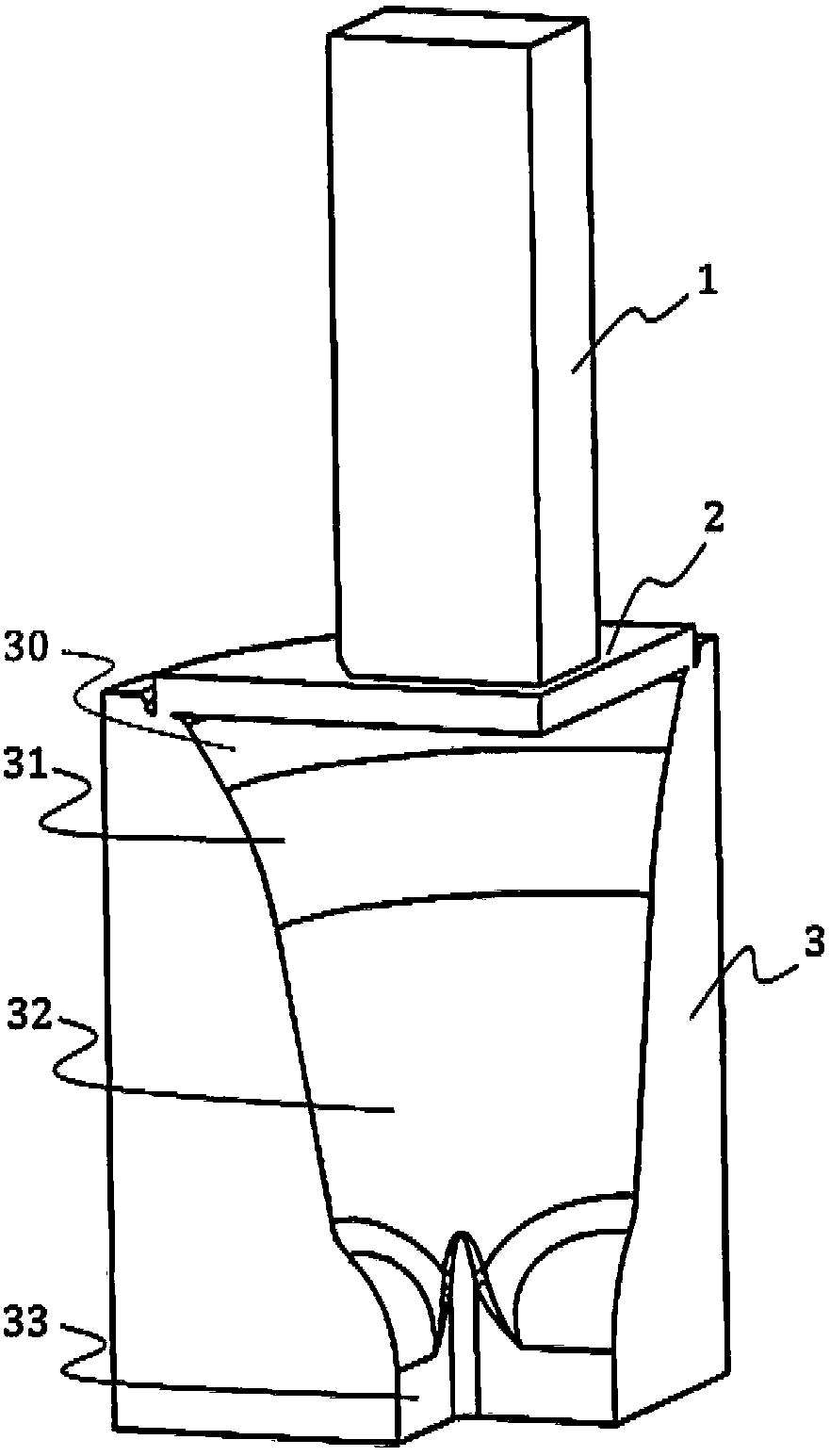

[0021] Such as figure 1 As shown, the tapered die 3 of this embodiment includes a two-stage structure of an upper part and a lower part, wherein: the upper part includes: a first taper 30, a second taper 32 intersecting with it, and a A smooth transition section 31 with a sufficiently large radius between the second taper and the second taper, and the lower part is a rectangular hollow column structure 33 .

[0022] In t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com