Chemical raw material production equipment

A technology for production equipment and chemical raw materials, applied in the field of chemical raw material preparation equipment, can solve problems such as increasing difficulty, and achieve the effects of speeding up production efficiency and reducing process waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

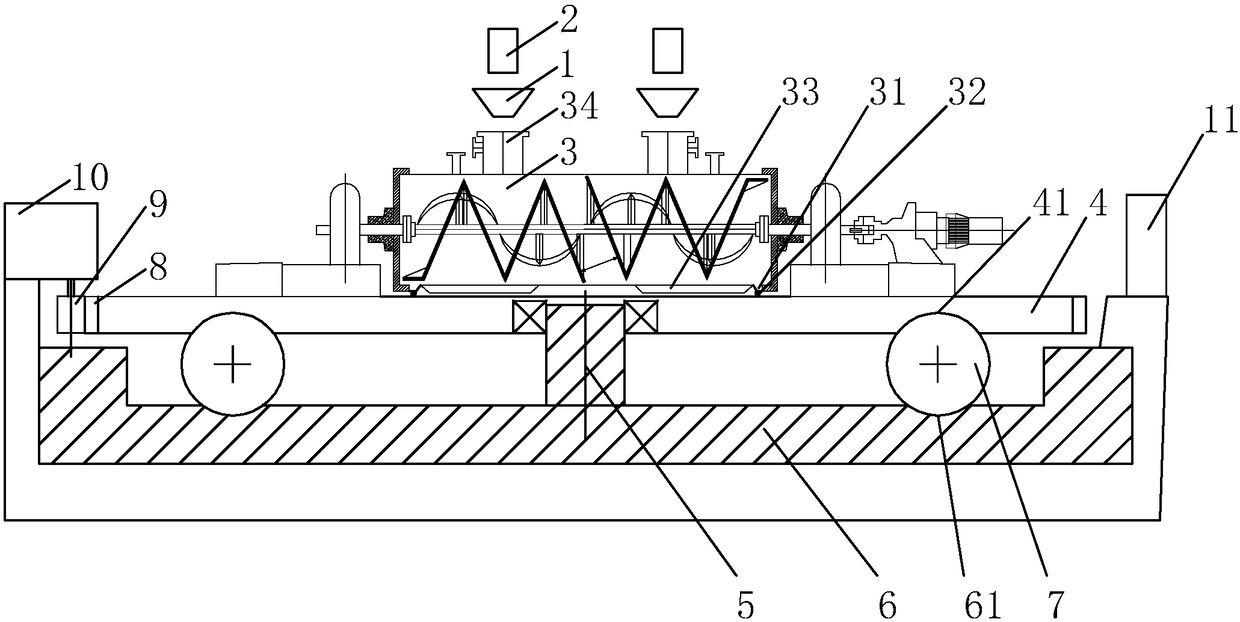

[0018] With reference to accompanying drawing, chemical raw material production equipment, equipment comprises feeding device, reaction device, receiving device; Feeding device, it comprises hopper 1 and feeding pipe 2; There is a rotating device at the bottom; the material receiving device is arranged on the side of the rotating device.

[0019] In this implementation, the rotating device includes a rotating table 4 that is flush with the floor of the workshop. The bottom of the rotating table 4 is connected to the rotating shaft 5 through a bearing, and the lower end of the rotating shaft 5 is fixed on a circular basin-shaped base 6 .

[0020] In this implementation, the base 6 is provided with an arc-shaped lower ring groove 61, the bottom of the turntable 4 is provided with an arc-shaped upper ring groove 41, and between the arc-shaped lower ring groove 61 and the arc-shaped lower ring groove 61, a plurality of steel ball7.

[0021] In this implementation, the base 6 is f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com