Drawing and straightening equipment of copper bars

A technology of equipment and copper bars, applied in the field of drawing and straightening equipment, can solve the problems of increasing the waste of the head and tail processes, reducing the side bending process, and large waste of materials, and achieves the effects of reducing energy consumption, reducing processes, and reducing process waste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

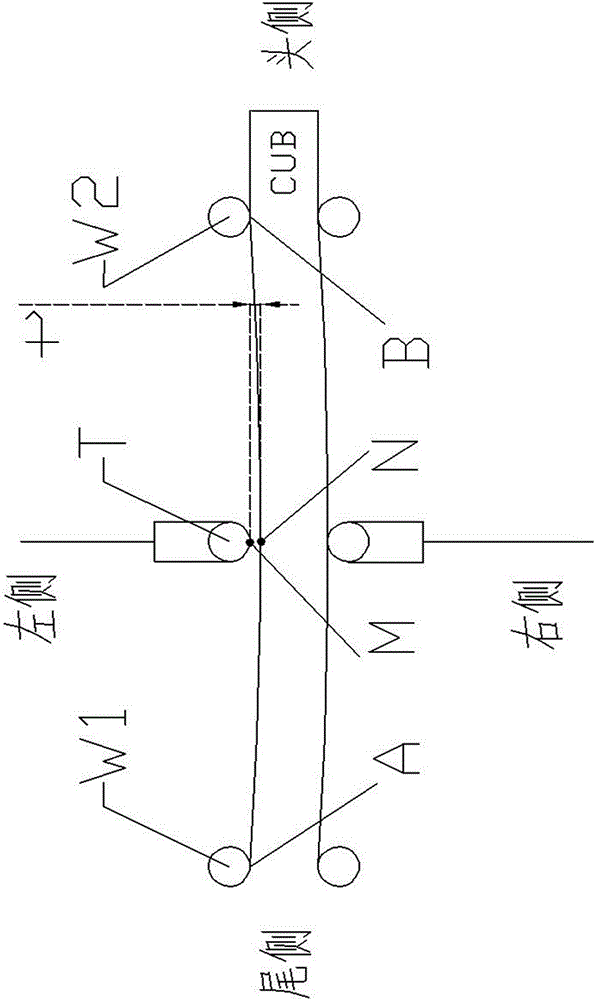

[0024] For the convenience of description, the present invention defines: "head side" is the direction in which the copper bar blank moves, "tail side" is its opposite direction, "left side" is the direction of the left hand side when facing the head side and back to the tail side, " Right” is the opposite direction to the left, such as image 3 shown.

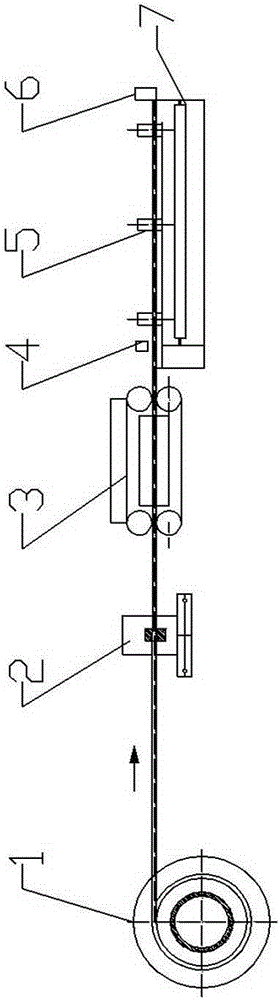

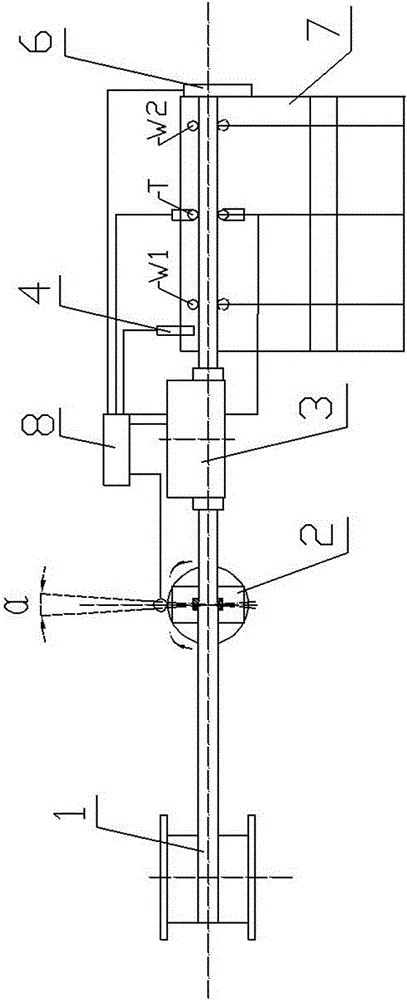

[0025] The copper bar drawing and straightening equipment of the present invention comprises a drawing die 2, a tire puller 3, a reciprocating section cutting machine 4, a bending measuring mechanism 5, a length fixing mechanism 6, a thermoplastic packaging system 7 and a controller 8 . The controller 8 adopts the field bus to control the intelligent automatic drawing and straightening of the entire production line, cutting to length, measuring and straightening.

[0026] The drawing die 2 is connected with the servo motor, and the servo motor is connected with the controller 8. Under the control of the controller 8, the dra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com