Hot isostatic pressure treatment method for chromium plane target material

A technology of hot isostatic pressing and treatment method, which is applied in the direction of metal material coating process, ion implantation plating, coating, etc., can solve the problems of low material strength and rigidity, workpiece deformation, bending, etc., to improve quality and reduce Side bending and deformation, the effect of low deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

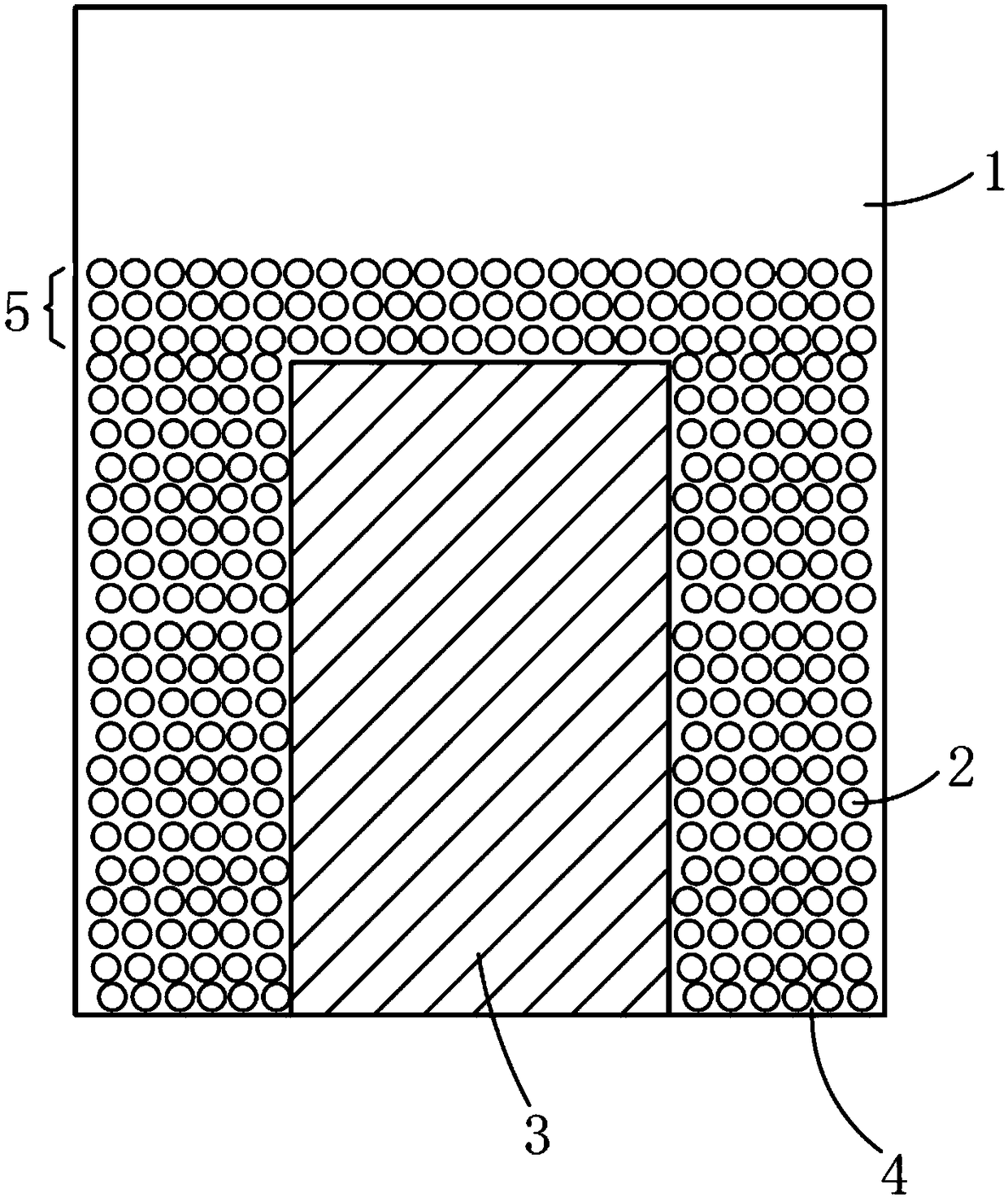

[0032] Chromium planar target hot isostatic pressing treatment method, figure 1 shown, including the following steps:

[0033] S1: Select a hot isostatic pressing furnace in which the furnace chamber 1 is larger than the target workpiece 3;

[0034] S2: place the target workpiece 3 vertically or horizontally in the furnace chamber 1, and leave a flow gap 4 between the target workpiece 3 and each inner wall of the furnace chamber 1, and leave a flow space above the target workpiece 3 ;

[0035] S3: Fill the furnace cavity 1 with ceramic beads 2, and the ceramic beads 2 fill the flow gap 4. The ceramic beads are ceramic beads 2 with a diameter of 6-10 mm, and ceramic beads 2 with a fluid spherical shape are selected. Ceramic beads 2 The diameter of the flow gap 4 is less than 0.5 times; the flow gap 4 is filled with at least 3 to 20 ceramic beads 2 in the width direction; preferably, the flow gap 4 is filled with at least 10 to 15 ceramic beads 2 in the width direction;

[00...

Embodiment 2

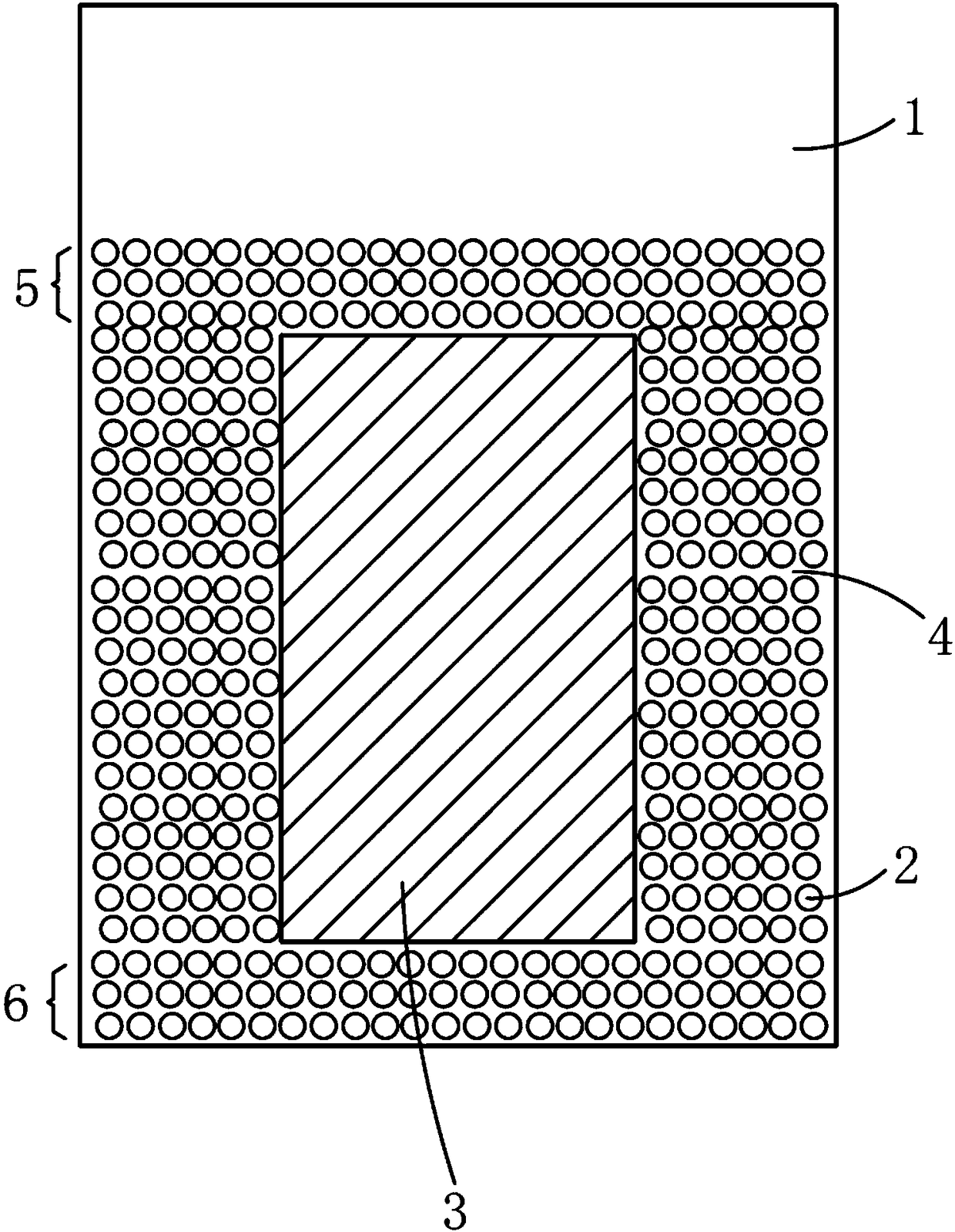

[0041] Chromium planar target hot isostatic pressing treatment method, figure 2 shown, including the following steps:

[0042] S1: Select a hot isostatic pressing furnace in which the furnace chamber 1 is larger than the target workpiece 3;

[0043] S2: Put ceramic beads 2 at the bottom of the furnace cavity 1 first, choose ceramic beads 2 with a diameter of 6-10 mm, and choose ceramic beads 2 in the shape of a fluid sphere to form a ceramic bead flow supporting layer 6 , and then place the target workpiece 3 on the ceramic bead flow supporting layer 6, and leave a flow gap 4 between the periphery of the target workpiece 3 and the inner wall of the furnace chamber 1. The ceramic bead flow support layer 6 is filled with at least 10-50 ceramic beads 2 in the height direction, preferably, the ceramic bead flow support layer 6 is filled with at least 20-30 ceramic beads 2 in the height direction.

[0044] Then place the target workpiece 3 vertically or horizontally in the furna...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com